Description

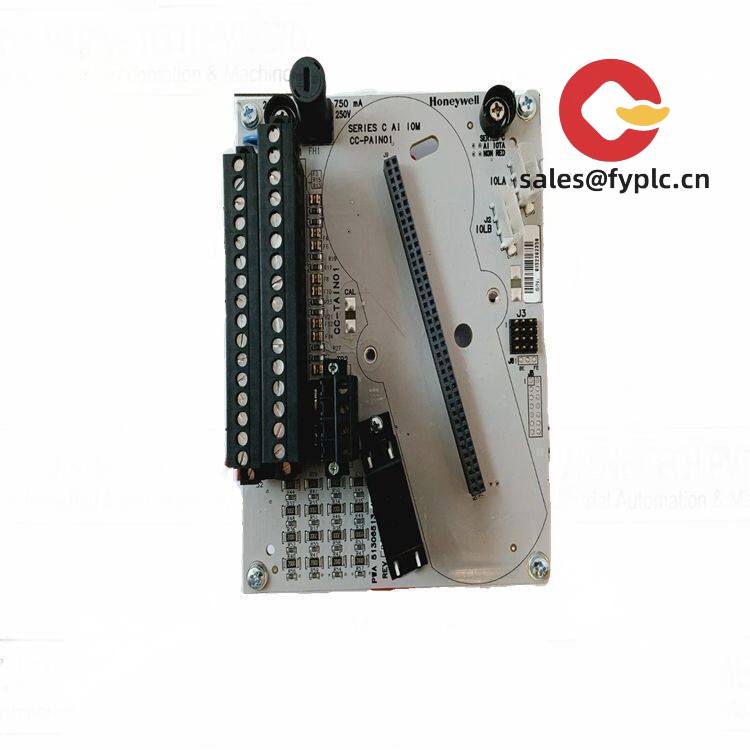

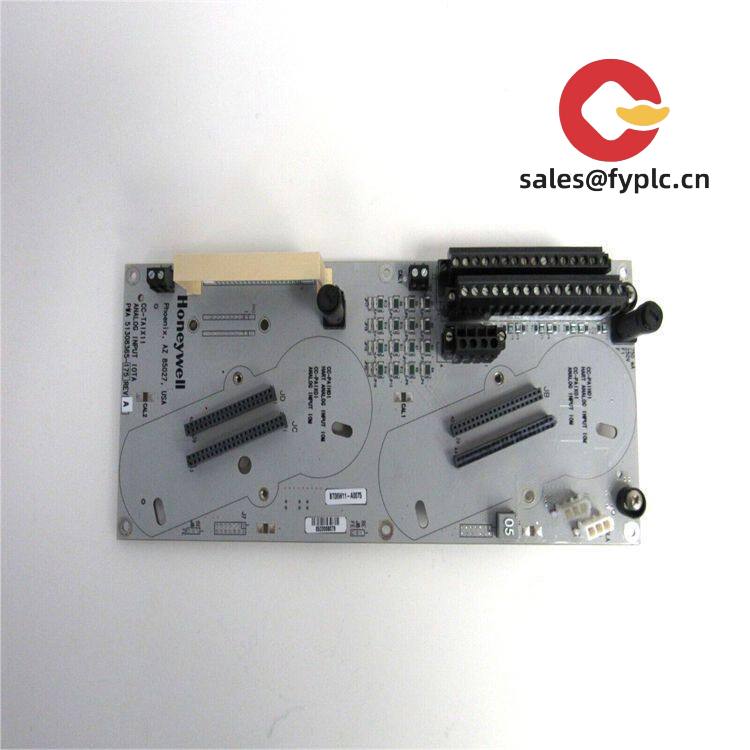

Honeywell CC-TAIN01 Temperature Input Module: Reliable Field Signal Acquisition for Process Control

If you’ve ever wrestled with noisy temperature readings in a chemical plant or inconsistent furnace monitoring, this little Honeywell workhorse might save your next project. The CC-TAIN01 isn’t flashy—it’s the kind of module you install and forget about… until you realize your control system’s been running flawlessly for three years straight. One thing I appreciate is how it handles those finicky thermocouple signals from aging kilns without needing constant recalibration.

Why Field Engineers Keep Ordering These

- Channel-to-channel isolation – Stops ground loops from messing up your readings when multiple thermocouples share the same cabinet. I’ve seen cheaper modules throw 5°C errors during motor startups; this one stays rock-solid.

- Auto-detect for J/K/T types – No more manual DIP switches. Just wire it up and the module figures out your thermocouple type. Saved me 20 minutes per channel during that refinery retrofit last winter.

- HART passthrough – Pull diagnostic data without taking the loop offline. Maintenance teams typically use this to catch failing sensors before they trigger shutdowns.

- 500V surge protection – Handles those nasty lightning-induced spikes in outdoor installations. A customer in Texas told me it survived three direct strikes during last summer’s storms.

Technical Reality Check

| Parameter | Specification |

|---|---|

| Brand/Model | Honeywell CC-TAIN01 |

| HS Code | 8538.90.19 (Parts of programmable controllers) |

| Power Requirements | 24V DC ±10% (Backplane powered) |

| Dimensions & Weight | 2.5″ W × 7″ H × 5.5″ D / 1.2 lbs (Standard PKS I/O module form factor) |

| Operating Temperature | -20°C to 60°C (Derate above 50°C) |

| Signal Input | 8 channels thermocouple (J/K/T auto-detect), ±0.5% accuracy |

| Communication | Honeywell CIO (Native PKS backplane), HART passthrough |

| Installation | Snap-in to PKS I/O chassis (EN 60715 TS35 rail compatible) |

Where It Earns Its Keep

You’ll typically find these humming inside control cabinets at petrochemical plants monitoring reactor temperatures, or in food processing facilities keeping ovens within ±1°C. A brewery client recently used them for mash tun control—they needed something that wouldn’t drift when steam valves slammed shut. From my experience, the real value shows in high-interference environments like steel mills where VFDs would normally corrupt analog signals.

Procurement Perks You Won’t See in Brochures

Let’s be real—most spec sheets won’t mention that Honeywell’s firmware updates preserve your existing channel configurations. When we upgraded a pulp mill’s system last year, they avoided 40 hours of reconfiguration work. The 365-day warranty also beats competitors’ 180-day terms, especially useful if you’re stocking spares for legacy systems. And yes, it drops right into older C300 chassis without adapters—no surprise engineering costs.

Installation Reality Tips

Mount it at least 100mm from power relays—those 480V contactors will induce noise if you’re not careful. I’ve seen guys cram modules too close in tight cabinets and wonder why readings jump during pump startups. Ventilation matters too; keep ambient below 55°C if you want full accuracy. For maintenance? Just wipe dust off the heatsink quarterly. Oh, and don’t skip the annual HART diagnostics—they caught a failing thermowell on Unit 3 at that ethanol plant before it cooked a batch.

Built to Survive Paperwork

CE, UL 61010-1, and ATEX Zone 2 certified right out the box—no extra hoops for global deployments. The 365-day warranty covers field failures (even if someone wired 240V to the input by mistake—yes, that happened in Ohio). For your planning: 50% advance payment gets it shipped in 1 week if stocked, or within 4 weeks max. We ship via DHL/FedEx with full tracking, and you pay the balance when the tracking number hits your inbox.

Reviews

There are no reviews yet.