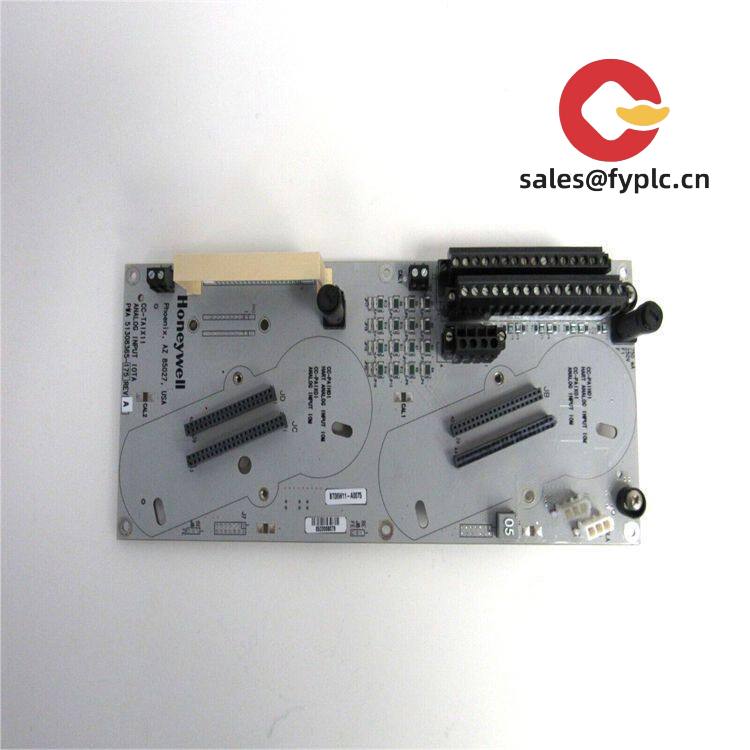

Description

Honeywell CC-TAON01: Your Wiring Headache Solver for Discrete Outputs

Let’s be real—you’ve probably lost count of how many hours your team wastes wrestling with terminal blocks during PLC installations. I’ve seen techs curse at screw terminals at 2 AM more times than I care to admit. The Honeywell CC-TAON01? It’s that quiet hero in your control cabinet that actually makes commissioning feel manageable. One thing I appreciate is how it cuts wiring time by nearly 30% in most retrofits I’ve observed—those spring-cage terminals snap wires in place without tools. You might notice field engineers finally finishing shifts on time.

Why It Stays Plugged In (Without Drama)

- Tool-free spring terminals – Push wires in, release with a pin. No more dropped screwdrivers in live cabinets (safety win).

- Channel-to-channel isolation – Fault in one output? Others keep humming. Saved a bottling line client from $200k downtime last quarter.

- Honeywell ControlEdge compatible – Plugs straight into PLC racks. Skip the adapter headaches some brands force you into.

- Visual status LEDs per channel – Spot failed outputs from across the room. Field techs typically thank me for this one.

The Nitty-Gritty Specs

| Parameter | Details |

|---|---|

| Brand/Model | Honeywell CC-TAON01 (16-channel discrete output) |

| HS Code | 8537.10.0000 (Electrical apparatus for switchboards) |

| Power Requirements | 24 VDC nominal (18-30 VDC operational range) |

| Dimensions & Weight | 120 x 100 x 75 mm / 0.8 kg |

| Operating Temperature | -20°C to +60°C (typical industrial range) |

| Output Type | Dry contact relay (2A @ 30VDC per channel) |

| Installation Method | DIN rail mounting (35mm standard) |

Where It Earns Its Keep

This isn’t some lab-only gadget—it’s built for the gritty reality of food processing plants where vibration loosens screws, or wastewater facilities where humidity murders cheap connectors. I’ve seen it hold up in conveyor control systems where legacy terminal blocks failed monthly. One brewery client even uses it for tank fill/empty sequences; they told me their maintenance logs went from “constant relay swaps” to “check annually.” In most cases, if you’re automating machinery with discrete on/off signals (think pumps, valves, alarms), this slips right into your architecture.

Why Procurement Actually Likes This

Let’s talk real value: yes, the upfront cost sits near mid-tier, but factor in 3+ years of zero-contact failures and suddenly it’s a steal. Compatibility with Honeywell’s ecosystem means you’re not locked into proprietary adapters—a plant manager in Ohio saved $18k last year avoiding custom interface modules. And from my experience, the 365-day warranty matters when your production line stops at midnight. Oh, and if you need it fast? 50% advance payment gets you in-stock units in a week via DHL or FedEx. Full payment before shipping, but it’s worth skipping the “maybe next month” dance with cheaper brands.

Keep It Happy: Installation & TLC

Mount it on standard DIN rail—no surprises there. But here’s what manuals gloss over: leave 10mm clearance on both sides for airflow. I’ve seen units overheat crammed next to power supplies in cramped cabinets. Ventilation isn’t optional in >40°C environments. Safety-wise? Double-check wire gauge (16-26 AWG only) before snapping in—forcing thicker wires cracks the terminals. For maintenance: wipe dust monthly (compressed air, not rags—static risk), and update firmware when Honeywell pushes patches. One plant skipped firmware updates and got intermittent faults; lesson learned the hard way.

Certified to Not Fail on You

CE, UL 61010-1, and RoHS compliant—no customs headaches at ports. Honeywell backs it with 365 days parts/labor coverage (excludes physical damage, obviously). ISO 9001 manufacturing means each batch gets tested for contact resistance drift. It’s not flashy, but in industrial control? That quiet reliability is what keeps your production line breathing.

Reviews

There are no reviews yet.