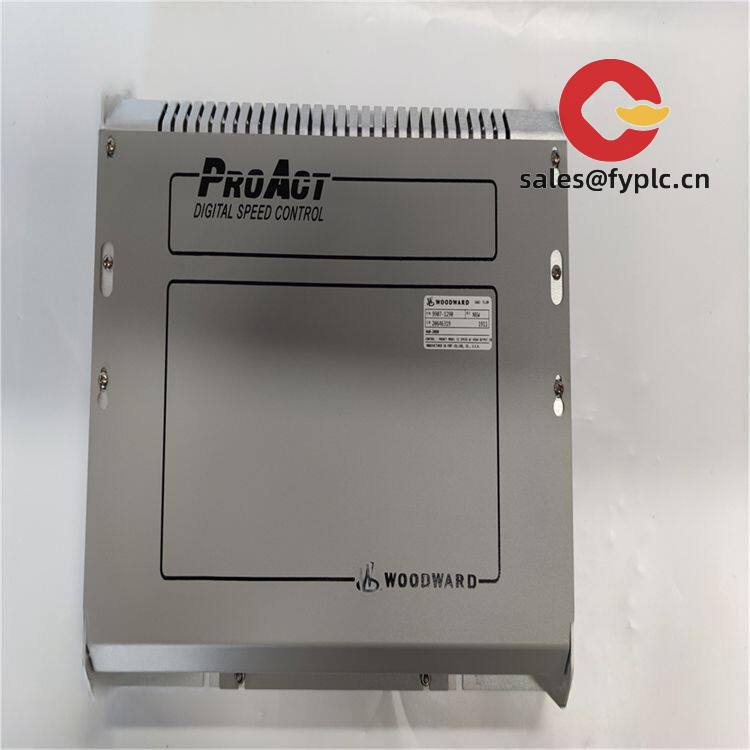

Description

Woodward 9907-028 Load Sharing & Speed Control – Stable, coordinated speed and load control for engines and gensets

The Woodward 9907-028 is part of the well-proven 2301A family, designed to regulate prime mover speed and enable precise load sharing between parallel generators. From my experience, this unit is chosen when operators want the simplicity and reliability of analog control with the accuracy needed for isochronous or droop operation. It typically interfaces with a magnetic pickup (MPU) for speed sensing and drives a proportional actuator with stable 0–200 mA current output, making it a practical drop-in for many Woodward-actuated diesel or gas engines.

Our Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Isochronous or droop speed control – Supports steady frequency operation or governor droop for stable parallel running.

- Load sharing capability – Works with Woodward load-sharing lines to balance kW between paralleled units, reducing circulating currents.

- Stable actuator drive – Analog current output (commonly up to 0–200 mA) to Woodward proportional actuators for precise fuel/steam control.

- MPU speed input – Uses magnetic pickup feedback for accurate speed measurement, typically across a wide frequency range.

- Remote speed/setpoint inputs – Accepts external raise/lower contacts and analog setpoint (e.g., 4–20 mA) for operator or PLC trim.

- Soft ramping and dynamics – Adjustable stability/droop/response trims help avoid hunting and reduce mechanical stress.

- Rugged analog platform – Proven 2301A architecture that in many cases outlasts digital alternatives in harsh sites.

Technical Specifications

| Brand / Model | Woodward 9907-028 (2301A series) |

| HS Code | 9032.89 (Automatic regulating or controlling instruments and apparatus) |

| Power Requirements | 24 VDC nominal (typically 18–32 VDC, variant-dependent) |

| Operating Temperature | –40 to +70 °C typical for 2301A-class units |

| Signal Input Types | MPU speed input; remote setpoint (e.g., 4–20 mA) and raise/lower contacts |

| Signal Output Types | Actuator drive current (commonly up to 0–200 mA); load sharing line interface |

| Communication Interfaces | None (analog control) |

| Installation Method | Panel/backplate mount inside control cabinet; shielded wiring recommended |

| Dimensions & Weight | Chassis unit for standard control cabinets; contact us for exact build dimensions |

Application Fields

This model is commonly used on:

- Diesel and gas generator sets requiring parallel operation and tight frequency control

- Industrial engines driving compressors, pumps, or blowers where steady speed is critical

- Marine auxiliary gensets with analog load sharing lines

- CHP and cogeneration systems targeting stable kW and smooth load transitions

- Oil & gas sites where rugged, non-networked speed governors are preferred

One thing I appreciate is how forgiving the 2301A platform is during commissioning—tuning the gain and stability trims usually brings a hunting unit into a steady state without hours of trial-and-error.

Advantages & Value

- Reliability in tough environments – Analog control with fewer failure points; typically less sensitive to electrical noise than some digital units.

- Compatibility – Designed to work with Woodward MPUs, actuators, and load sharing lines—reducing integration risk.

- Cost-effective lifecycle – Minimal software or firmware upkeep; spare parts and on-site skills are widely available.

- Predictable performance – Stable frequency control improves power quality and protects downstream assets.

Customer feedback from a gas plant retrofit: “Swapping to 9907-028 got our two units to share within a couple percent. Once we dialed in droop and stability, load steps stopped tripping the breaker.”

Installation & Maintenance

- Cabinet environment – Install on a rigid backplate in a dry, ventilated control cabinet. Keep away from high-heat sources and VFD noise.

- Power & grounding – Use a clean 24 VDC supply with proper grounding. In many cases, a dedicated supply and surge suppression improves stability.

- Wiring practices – Shielded, twisted pair for MPU and analog lines; separate from high-voltage cables. Bond shields at one end only.

- Actuator linkage – Verify free travel and correct polarity (forward/reverse acting) before load tests.

- Tuning – Set droop/isochronous mode and adjust gain/stability with the unit under load; ramp rates help avoid overshoot.

- Routine checks – Inspect terminals, clean dust, verify setpoints, and confirm load sharing line integrity every 6–12 months.

This is an analog device—no firmware updates—so most maintenance comes down to good wiring hygiene and occasional recheck of trims after mechanical work on the engine or actuator.

Quality & Certifications

- Manufacturer quality system: ISO 9001 (typical for Woodward facilities)

- Conformity: CE and UL/cUL markings are commonly associated with 2301A-series builds

- RoHS: Many variants comply; exact status depends on production batch

- Warranty: 365 days

Commonly Paired Components

- Woodward proportional electric actuators (various torque ratings) for fuel rack or throttle control

- Woodward magnetic pickups (standard 5/8-18 or M16 threads) for flywheel speed sensing

- Woodward load-sharing accessories and kW/load transducers where parallel operation is required

Notes: Specific electrical ratings and mechanical options can vary by 9907-028 build. If you share your actuator model and engine details, we can confirm polarity (forward/reverse acting), output current range, and wiring diagram before shipment.

Reviews

There are no reviews yet.