Description

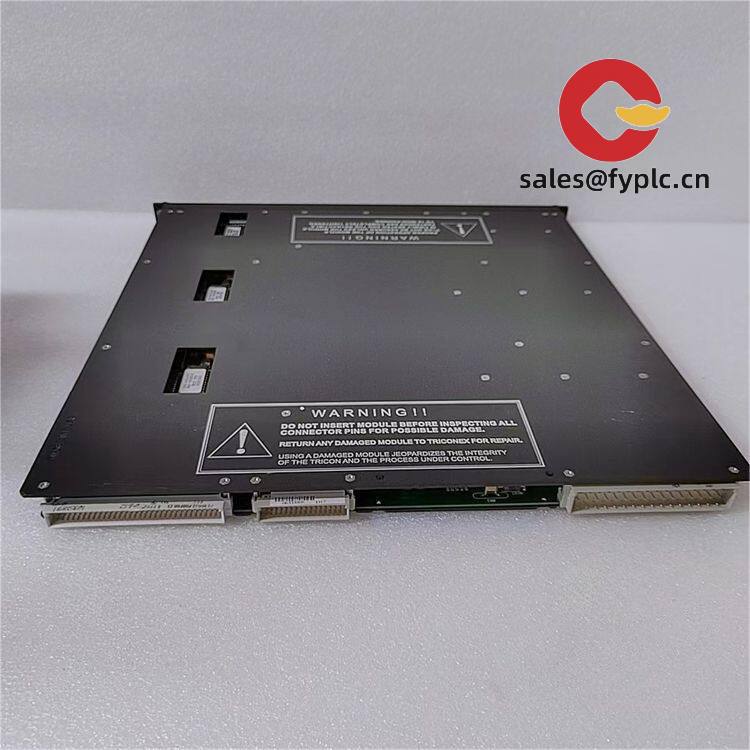

TRICONEX 4609 – TMR Safety System I/O Interface Module for Tricon Applications

The TRICONEX 4609 is commonly used within Triconex Tricon safety instrumented systems as an I/O interface/termination component, pairing with standard Tricon I/O cards for SIL3-rated applications. From my experience, integrators choose the 4609 when they need a dependable interface between field wiring and the TMR backplane, especially in process safety, ESD, and F&G projects where diagnostic coverage and uptime matter.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week for in‑stock items; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

Key Features

- TMR compatibility – Designed to operate within the Tricon triple modular redundancy architecture for continuous operation.

- Reliable field termination – Provides organized, serviceable connection points between field signals and Tricon I/O cards.

- Diagnostic-friendly layout – LED/label provisions and clear channel mapping typically simplify commissioning and troubleshooting.

- Hot-swap workflow support – In most cases, supports standard Tricon online maintenance practices to reduce downtime.

- Industrial-grade build – Appears to feature robust PCB construction and conformal coating practices common to Triconex modules.

- SIL3 usage when system-approved – When applied with Tricon processors and TÜV-certified I/O, it fits in safety applications up to SIL3.

- Wiring flexibility – Suits typical process signals (digital/analog) depending on the I/O module it mates with (e.g., 3703E, 3721, 3625).

Technical Specifications

| Brand / Model | TRICONEX 4609 |

| HS Code | 8537.10 (Boards/panels for electric control, voltage ≤ 1000 V) |

| Power Requirements | Supplied by Tricon chassis/backplane; no separate external power typically required |

| Operating Temperature | Typically 0 to 60 °C (32 to 140 °F), non‑condensing environment |

| Signal I/O Types | Depends on paired Tricon I/O card; supports common DI/DO/AI/AO signal routing via termination interface |

| Communication Interfaces | Tricon backplane interface; field-side via terminal/connector set as provided by the assembly |

| Installation Method | Plug-in/termination assembly within Tricon system cabinet; tool-assisted field wiring |

| Dimensions & Weight | Standard Tricon card/termination form factor (contact us for exact measurements if required) |

Application Fields

The 4609 is typically selected for safety-critical control where certified Tricon performance is required:

- Emergency Shutdown (ESD) and High Integrity Pressure Protection Systems (HIPPS)

- Fire & Gas detection and shutdown logic

- Burner Management Systems (BMS) and boiler safety loops

- Turbomachinery protection and control

- Refineries, petrochemical plants, FPSOs, pipelines, and LNG terminals

Advantages & Value for Procurement

- System reliability – Built for continuous service in TMR safety architectures, supporting high availability.

- Compatibility – Works within the Tricon ecosystem; pairs well with cards like 3703E (DI), 3721 (AI), 3625 (DO), and standard Tricon processors.

- Lifecycle support – Access to spares and field-replaceable practices typically shortens outage windows.

- Cost control – Clean termination and channel mapping reduce wiring errors and rework during commissioning.

- Documentation & service – Clear labeling and diagnostics usually cut mean time to repair.

A maintenance lead in a Middle East gas plant told us the swap time for a 4609-based I/O bay was “measured in minutes rather than hours,” mainly due to predictable wiring layout and onsite spares.

Installation & Maintenance

- Cabinet & environment – Install in a clean, ventilated control cabinet (19-inch racks are common). Maintain ambient within the stated operating range, with proper grounding and EMC practices.

- Wiring – Use appropriately rated cable; respect shield termination conventions for analog signals. Torque terminals per manufacturer recommendations to avoid loosening.

- Safety – Follow lockout/tagout. Use ESD protection when handling cards. Verify system trip settings before returning to service.

- Commissioning – Validate channel mapping against P&IDs and I/O lists; perform loop checks and proof tests in accordance with site procedures.

- Routine maintenance – Periodic inspection for connector oxidation, dust cleaning with non‑static tools, review diagnostic logs, and apply approved firmware updates to the Tricon system when applicable.

Quality & Certifications

- Designed for use in IEC 61508 / SIL3 safety functions within the Tricon system (when used with certified components)

- CE and UL conformity typically available across the Triconex portfolio

- RoHS considerations depend on manufacturing lot and regional requirements

- Manufacturer warranty typically aligns with the 365-day coverage noted above

Recommended Supporting Components

- TRICONEX 3008 – Tricon main processor module for TMR control

- TRICONEX 3703E – Digital Input module (pairs well for discrete safety loops)

- TRICONEX 3721 – Analog Input module (for process transmitters)

- TRICONEX 3625 – Digital Output module (interposing relays/solenoids)

- Appropriate Tricon chassis/backplane and system power supplies

Reviews

There are no reviews yet.