Description

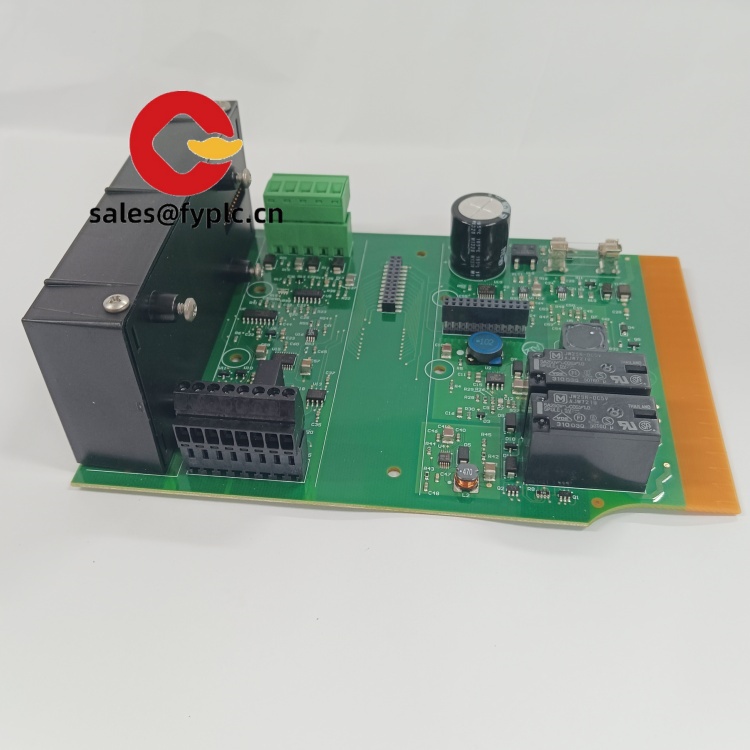

Alstom EPSD-0603 – Electronic Power Supply/Distribution Module for Rail Control Systems

The Alstom EPSD-0603 is commonly supplied as a rail‑grade electronic power supply/distribution (EPSD) module used in rolling stock control cabinets and signaling cubicles. From my experience, this series is chosen when operators need a compact, serviceable power interface with built‑in protection and status signaling. You might notice that it’s engineered for harsh environments typical of onboard systems—temperature swings, vibration, electrical noise—while keeping replacement straightforward for maintenance teams.

Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than 1 month at the latest

- Payment: 50% advance payment, full payment prior to delivery

- Express carriers: FedEx, UPS, DHL

- Each unit is function-checked before dispatch and packed for shock and moisture protection

Key Features

- Rail‑grade DC power interface – Typically designed to accept vehicle battery DC and stabilize output for downstream control electronics.

- Integrated protection – Over‑voltage, short‑circuit, and thermal safeguards are usually included to protect both the module and connected loads.

- Status signaling – Power‑OK and fault indication via front indicators and dry‑contact outputs help technicians troubleshoot quickly.

- Serviceable, plug‑in form factor – Front‑accessible fasteners and keyed connectors make swap‑outs fast during routine maintenance.

- Built for harsh environments – Conformal coating and rugged construction to handle vibration, shock, and wide temperature ranges found on rolling stock.

- Cabinet integration – Fits Alstom control cubicles; wiring and mounting are straightforward for standard rail cabinets.

Technical Specifications

Below reflects the typical characteristics for EPSD‑series modules used in rail applications. Exact parameters can vary by build code and revision; please verify against your nameplate and drawings before ordering.

| Brand / Model | Alstom EPSD-0603 |

| Product Category | Electronic Power Supply / Distribution Module for Rolling Stock |

| HS Code (reference) | 8537.10 – Boards/panels for electric control or distribution (final classification depends on configuration and destination) |

| Power Requirements | Vehicle DC supply, typically within 24–110 VDC range (confirm rating on unit label) |

| Operating Temperature | Designed for wide‑range rail environments; Class TX (−40 to +70 °C) is commonly specified for similar modules |

| Signal I/O Types | Dry‑contact status outputs (Power‑OK/Fault), enable/remote input; front LEDs for status |

| Communication Interfaces | Not typically required; status via contacts (variant dependent) |

| Installation Method | Panel/rack mounting in Alstom control cubicles; front plug‑in with captive screws and keyed connectors |

| Design Standards (typical) | EN 50155 (railway electronics), EN 50121‑3‑2 (EMC), EN 61373 (shock & vibration), EN 45545‑2 (fire safety) – confirm per unit |

Application Fields

The EPSD-0603 is suited to onboard power conditioning and distribution within traction control, braking control, door systems, HVAC controllers, and signaling/communication cabinets. In many cases, operators use it to isolate and stabilize auxiliary DC power feeding PLCs, relay logic, and I/O modules so those subsystems stay stable during battery dips or cranking events. One fleet engineer told us it “bought back hours during night maintenance windows” because swaps were predictable and wiring was clearly labeled.

Advantages & Value

- Reliability under rail conditions – Built for vibration, shock, and electrical noise typical of rolling stock, reducing nuisance trips.

- Compatibility – Pairs with Alstom cubicles and wiring conventions; fewer surprises during retrofit projects.

- Lifecycle cost savings – Serviceable, plug‑in design shortens MTTR and avoids redesign costs when replacing like‑for‑like.

- Support and traceability – Unit serials and revision tracking make configuration management easier during audits.

Installation & Maintenance

- Cabinet & environment – Install in a sealed control cabinet with adequate ventilation. Keep ambient within the specified range and away from condensation.

- Mounting – Use the designated rack/panel points and captive screws. Ensure the ground/earth bonding is clean and secure.

- Wiring – Follow the wiring diagram on the module label or drawing set. Use ferruled leads, correct crimp tools, and observe polarity. Protect upstream with the rated DC breaker/fuse.

- Safety – De‑energize the vehicle DC supply and verify absence of voltage before handling. Allow time for internal capacitors to discharge.

- Routine checks – Inspect connectors for looseness, look for discoloration or odor, clean dust with dry air, and verify status LEDs and dry‑contact reporting.

- Calibration/Firmware – If your variant includes set‑points or firmware, document versions and update only with the approved package for the exact build code.

Quality & Certifications

Units are typically supplied with CE marking. For rolling stock, compliance is commonly aligned to EN 50155, EN 50121‑3‑2, EN 61373, and EN 45545‑2 requirements for the designated vehicle class. If your project requires additional documentation (e.g., test reports, CoC), we can align to your acceptance checklist. Manufacturer’s warranty typically applies; our coverage is 365 days from delivery.

Practical Notes Before You Order

- Share the complete part number and hardware/firmware revision printed on your existing module.

- Confirm input DC rating and any special I/O options (some fleets use custom signaling).

- Send a photo of the front and rear connectors if you’re replacing a legacy variant; prevents pinout mismatches.

Reviews

There are no reviews yet.