Description

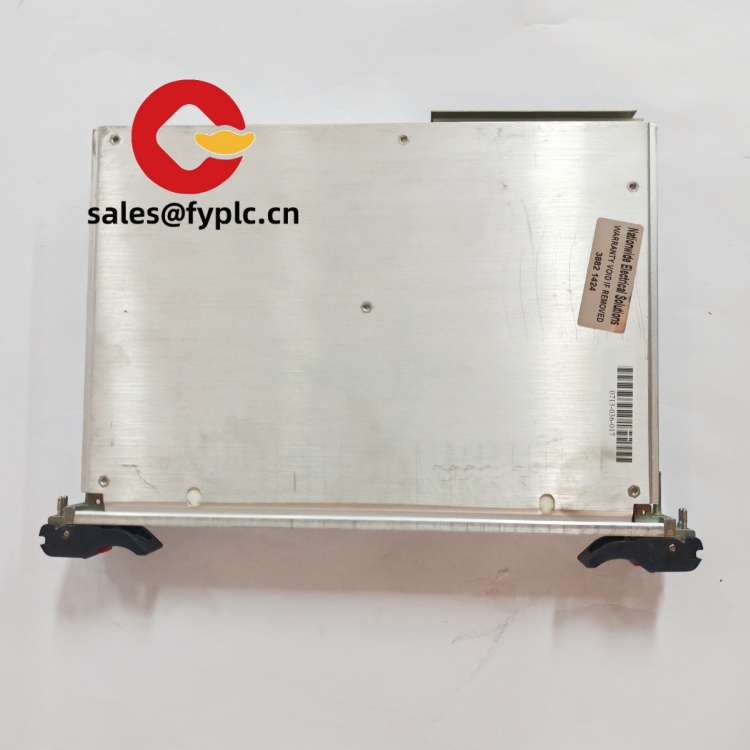

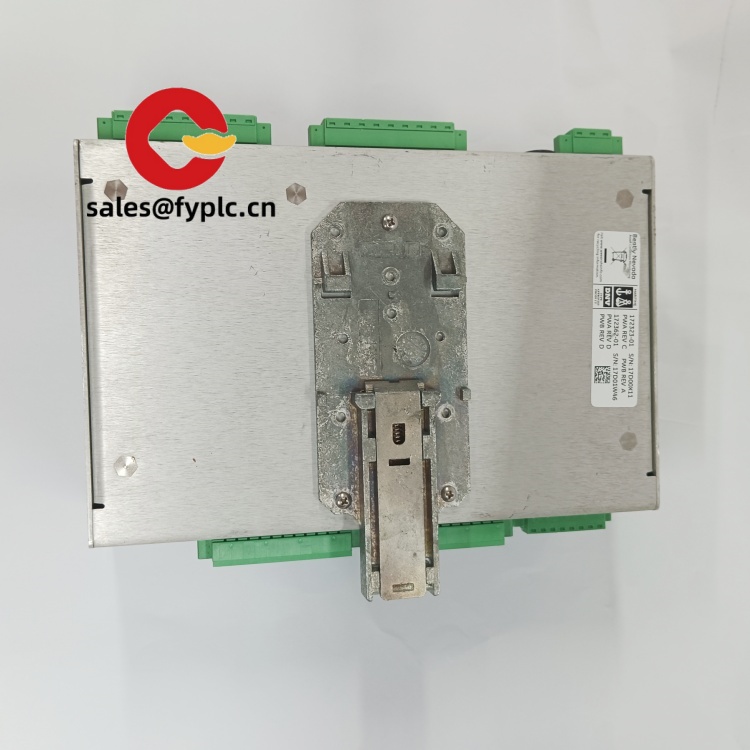

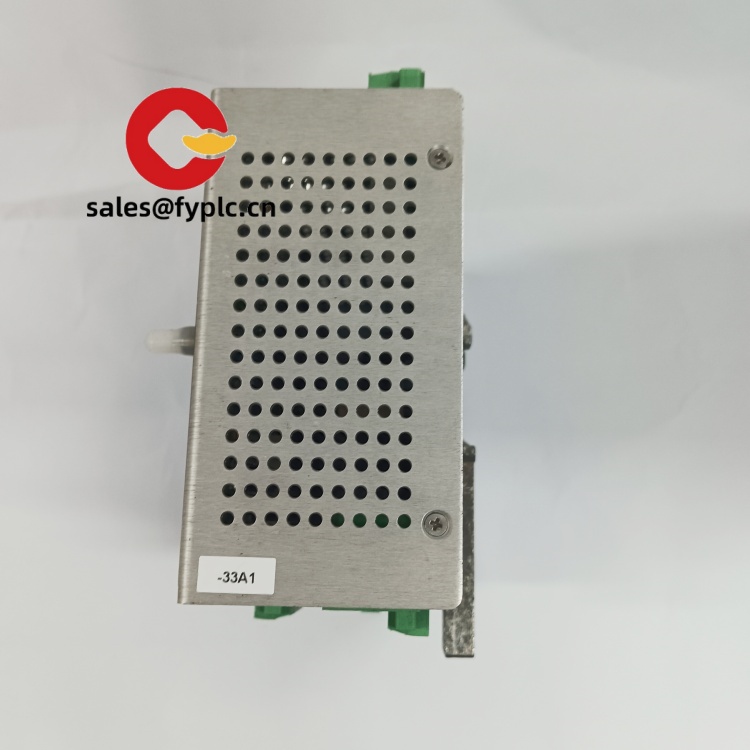

Bently Nevada 1900/65A (Assembly 172323-01) – General‑Purpose Equipment Monitor for Vibration, Position, and Speed

The Bently Nevada 1900/65A is a compact, standalone condition monitoring and protection monitor designed for small and mid‑size rotating assets—pumps, fans, motors, compressors—where a full 3500 rack would be excessive. Assembly 172323-01 typically refers to a specific factory build of the 1900/65A, combining standard vibration/Keyphasor support with industrial power and field I/O. From my experience, it’s a go‑to when you need reliable trips, clean 4–20 mA outputs for the DCS, and straightforward Modbus integration without a large footprint.

Our Order Placement Process and Guarantees

-

- – Warranty: 365 days from delivery

-

- – Delivery: 1 week if in stock; no more than 1 month at the latest

-

- – Payment: 50% advance; full payment prior to delivery

- – Express options: FedEx, UPS, DHL

Key Features

- Multi‑purpose monitoring – Accepts proximity probes (shaft vibration/position), velocity sensors, and accelerometers for broad machine coverage.

- Speed/Keyphasor support – Tachometer/Keyphasor input enables speed tracking, phase, and alarm logic tied to running speed.

- Integrated protection relays – Programmable relay outputs for Alert/ Danger trip, typically used to interlock drives and protect equipment.

- 4–20 mA outputs – Scalable analog signals for DCS/PLC trending without extra signal conditioners.

- Buffered dynamic outputs – Technicians can connect analyzers for waveform/FFT without disturbing the process signal.

- Modbus connectivity – RS‑485 (Modbus RTU) and, in many cases, an Ethernet option for Modbus TCP, simplifying SCADA integration.

- Compact footprint – Fits inside crowded MCCs or local junction panels; wiring is straightforward and well‑labeled.

- Robust alarm strategy – Dual‑level alarms, latching/non‑latching behavior, startup inhibit and timed OK logic to avoid nuisance trips.

Technical Specifications

| Brand / Model | Bently Nevada 1900/65A (Assembly 172323-01) |

| HS Code | 9031.80 (Measuring/monitoring instruments, other) |

| Power Requirements | 24 VDC nominal (typically 18–36 VDC), power consumption ~10 W |

| Dimensions & Weight | Compact panel‑mount enclosure; approx. 200 × 120 × 60 mm; about 1.0 kg (varies by build) |

| Operating Temperature | -20 to +65 °C (typical industrial range) |

| Signal Input Types | Eddy‑current proximity probes (shaft vibration/position), IEPE accelerometers, velocity transducers, Keyphasor/tach input |

| Outputs | 4–20 mA analog, programmable relay contacts (Alert/Danger), buffered dynamic test outputs |

| Communication Interfaces | RS‑485 (Modbus RTU); Ethernet Modbus TCP available on certain assemblies |

| Installation Method | Panel mount; DIN‑rail with adapter (site practice varies) |

Application Fields

Typically used on API and non‑API pumps, cooling‑tower fans, blowers, small compressors, extruder drives, and general‑purpose motors/gearboxes. You might notice that it’s particularly handy in brownfield plants where adding a few channels of protection plus Modbus data can extend asset life without a major controls project.

- Water and wastewater: pump skids, lift stations, aeration blowers

- Oil & gas / petrochem: process pumps, small compressors, auxiliary machines

- Power generation: ID/FD fans, condensate and boiler feed support equipment

- Pulp & paper / mining: conveyors, refiners, mill drives where protection trips are required

Advantages & Value

- Cost‑effective protection – In many cases, far less costly than a full rack system while covering the critical channels you actually need.

- Broad sensor compatibility – Works with mainstream proximity probes and velocity/accelerometer sensors, reducing spare parts complexity.

- Simplified integration – 4–20 mA plus Modbus means your DCS/PLC sees clean values without custom drivers.

- Reliable interlocks – Proven trip logic and relays help prevent secondary damage during high vibration events.

- Serviceability – Buffered outputs and clear diagnostics make field checks quick; maintenance teams typically appreciate that.

Installation & Maintenance

- Panel/Cabinet – Install in a clean, dry panel (IP54 or better). Allow ventilation space; avoid mounting near high‑heat sources.

- Power & Grounding – Provide a regulated 24 VDC supply; bond shields at one end; maintain a solid instrument ground to minimize noise.

- Wiring – Use shielded twisted‑pair for dynamic signals and Keyphasor. Keep sensor and power wiring segregated from VFD outputs.

- Configuration – Set machine‑specific alarm setpoints, OK thresholds, and startup inhibit. Verify 4–20 mA scaling at the control system.

- Routine checks – Inspect probe gaps and mounting torque, clean terminals, confirm relay operation during planned shutdowns.

- Firmware & backups – Keep configuration files backed up and, where applicable, confirm firmware compatibility before updates.

A maintenance lead at a chemical plant told us they swapped in a 1900/65A during a short outage and had Modbus data trending in SCADA the same afternoon. The buffered outputs made their acceptance testing faster than expected.

Compatible Sensors & Accessories (Examples)

- Bently Nevada 330180 – 3300 XL Proximitor Sensor for 5 mm/8 mm probe systems

- Bently Nevada 330130 – 3300 XL Extension Cable (various lengths/options)

- 3300 XL Proximity Probes – 5 mm or 8 mm tip probes for shaft vibration and axial position

- Bently Nevada 330500 Velomitor – Industrial velocity transducer for casing vibration

Quality & Certifications

- CE compliant

- UL/cUL (typical for industrial monitoring assemblies)

- RoHS conformant build in most configurations

- Manufactured under ISO 9001 quality systems

- Our warranty: 365 days

What to Provide for Quotation

- Exact assembly/build (1900/65A, Assembly 172323-01) and desired communication option

- Sensor types and quantities (proximity/accelerometer/velocity, cable lengths)

- Analog outputs required (number and scaling) and relay logic preferences

- Desired delivery window and shipping method (FedEx/UPS/DHL)

Reviews

There are no reviews yet.