Description

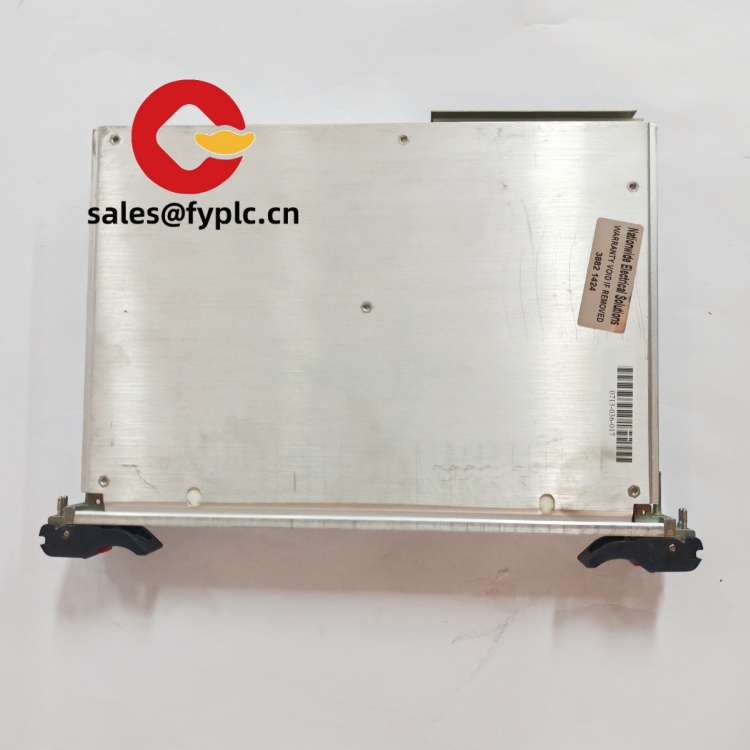

CCC PSMU-350-34 Industrial Power Supply Module – 34 V, 350 W for Control Cabinets

The CCC PSMU-350-34 is a 350 W industrial-grade power supply module built for stable 34 VDC output in factory automation, motion systems, and test rigs where uptime is everything. From my experience, this 34 V range is a sweet spot for servo amplifiers, mid-voltage DC actuators, and custom machine assemblies that don’t want the heat or losses of step-up stages. You might notice that it blends the usual industrial safeguards—overvoltage, short-circuit, and thermal protection—with the sort of wiring convenience panel builders actually want.

Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than 1 month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- 34 VDC single output (350 W class) – Suited to mid-voltage motion drives, valves, and instrumentation that prefer a clean 34 V rail.

- Universal AC input – Typically supports 85–264 VAC, 47–63 Hz, making it practical for multi-site deployments.

- Industrial protections – OVP/OCP/SCP/thermal safeguards help protect loads and reduce unplanned downtime.

- Stable regulation – Designed for low ripple and good transient response under varying machine loads.

- Cabinet-friendly form factor – Panel/chassis mounting fits standard control panels; DIN-rail mounting possible with bracket in many cases.

- Status signaling – Many units in this class provide DC-OK or remote enable; this model appears to support similar control signals.

Technical Specifications

| Brand / Model | CCC PSMU-350-34 |

| HS Code | 8504.40 (Static converters / switching power supplies) |

| Output Rating | 34 VDC nominal, 350 W class single output |

| Power Requirements | AC 85–264 V, 47–63 Hz (universal input, typical for this series) |

| Operating Temperature | Typically -10 °C to +60 °C, with output derating above +50 °C |

| Signal I/O Types | Single DC output; DC-OK / remote enable often available in this class |

| Communication Interfaces | N/A (no data bus; discrete status/control only in most cases) |

| Cooling Method | Forced-air or fan-assisted depending on enclosure and load |

| Installation Method | Panel/chassis mount; DIN-rail with adapter/bracket (if required) |

Application Fields

This model is commonly used where a clean 34 V rail is preferred over 24 V for headroom and reduced current. Typical deployments include:

- Motion control and servo stages that run best near 34 VDC

- Automated assembly, labeling, and packaging lines with mixed-voltage I/O

- Industrial PCs, machine vision lighting bars, and high-power sensors

- Test benches and burn-in racks needing a stable mid-voltage supply

- Custom robotics and AGV subsystems where 24 V isn’t quite enough

Advantages & Value

- Reliability under load – Consistent performance with protections that reduce field failures.

- Compatibility – Universal input and common terminal layouts make retrofits straightforward.

- Cost control – A direct 34 V rail can cut conversion losses and simplify wiring versus DC-DC stages.

- Serviceability – Clear status signaling and accessible terminals help maintenance teams move faster.

Feedback from a packaging OEM: “Swapping to a 34 V bus with this PSU let us downsize our wiring and the drives ran cooler. The team appreciated the predictable behavior when the line surged.”

Installation & Maintenance

- Cabinet standards – Mount in a clean, dry enclosure (IP54 or better for dusty sites). Keep 50 mm clearance around vents.

- Ventilation – Provide continuous airflow; for 350 W loads, forced-air is typically recommended to avoid thermal derating.

- Wiring – Use appropriately rated copper conductors; torque terminals to spec; separate AC input and DC output harnesses to reduce noise.

- Grounding – Bond protective earth; verify cabinet grounding continuity to minimize EMI.

- Safety – De-energize before servicing; bleed time for bulk caps can be >30 s after power-down.

- Routine maintenance – Quarterly dust cleaning; annual check of output voltage and ripple; firmware not typically applicable on passive PSU models.

- Spare strategy – Keep at least one unit on hand for each unique voltage per line to shorten MTTR.

Quality & Certifications

- CE and RoHS compliance expected for this class; UL/cUL listings commonly available on production units

- Manufactured under ISO 9001 quality systems (typical for this series)

- Warranty support: 365 days (replacement or repair as applicable)

Related Accessories & Supporting Components

- DIN-rail mounting bracket for panel conversion

- EMI/RFI AC input filters (to meet stricter site EMC)

- DC distribution terminal blocks and circuit protection (MCB/fuse)

- Buffer/UPS modules for ride-through during short outages

If you’re matching this supply to a servo or lighting load, share peak and steady-state currents—sizing with a small margin typically yields longer life and fewer nuisance trips.

Reviews

There are no reviews yet.