Description

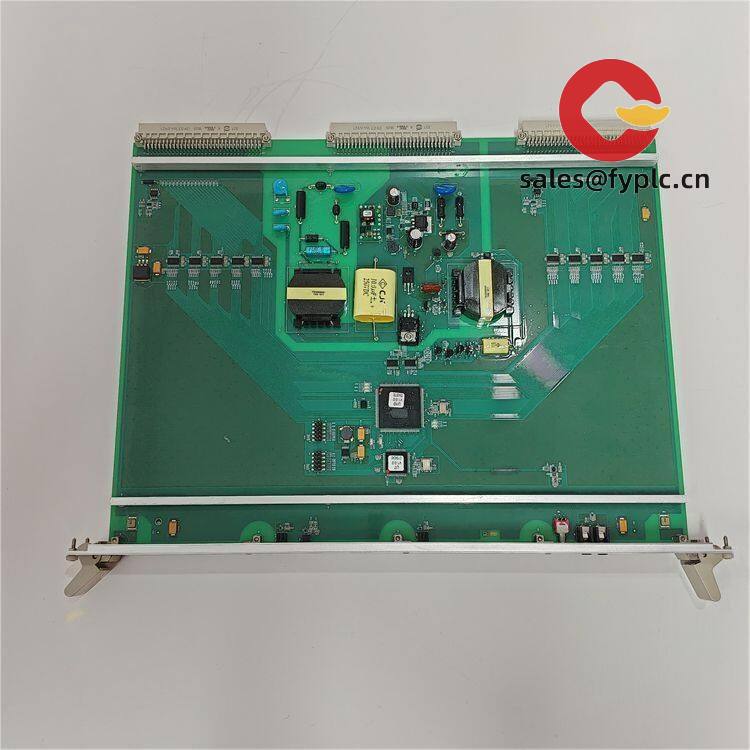

Bosch Rexroth CML40.2-SP-330-NA-NNNN-NW – Motion Logic Controller for Multi‑Axis Machines

The Bosch Rexroth CML40.2-SP-330-NA-NNNN-NW is a compact Motion Logic Controller typically used with IndraMotion MLC to coordinate drives, I/O, and real‑time Ethernet networks in machine automation. From my experience, the “SP‑330” performance class fits mid‑to‑high throughput machines—cartoners, converting lines, pick-and-place gantries—where synchronized motion and deterministic communication matter. You might notice that the “NA” variant seems to be aligned with North American conformity and labeling, while the “NNNN-NW” options indicate a base configuration without added special options.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days from delivery

- Lead time: typically 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- Motion + PLC in one – Coordinates multi‑axis motion and standard logic in a single controller, which typically reduces cabinet complexity.

- Deterministic real‑time Ethernet – Designed for SERCOS III or EtherCAT networks depending on licensed firmware, enabling synchronized drives and I/O.

- IndraWorks Engineering – Supports IEC 61131‑3 languages and Rexroth function blocks for faster commissioning and troubleshooting.

- Robust 24 VDC design – Industrial 24 V DC power input with protective grounding for stable operation in control cabinets.

- Modular I/O architecture – Works with Rexroth modular/remote I/O; in many cases it also interoperates with common third‑party I/O over standard fieldbuses.

- Service interfaces – Typically includes engineering Ethernet, USB service, and a serial port for legacy devices or diagnostics.

- Scalable performance – “SP‑330” performance level suits most mid‑range packaging, material handling, and assembly machines.

Technical Specifications

| Brand / Model | Bosch Rexroth CML40.2-SP-330-NA-NNNN-NW |

| Product Type | Motion Logic Controller (MLC hardware platform) |

| HS Code | 8537.10 (Boards/panels with programmable controllers, ≤1000 V) |

| Power Requirements | 24 V DC (typical industrial supply), protective earth required |

| Operating Temperature | Typically 0…+50 °C (non‑condensing); cabinet installation recommended |

| Signal I/O Types | Modular/remote I/O via real‑time Ethernet; no high‑density onboard I/O on the base CPU |

| Communication Interfaces | Engineering Ethernet (RJ45), real‑time Ethernet (e.g., SERCOS III/EtherCAT, license‑dependent), USB service, serial (commonly RS‑232) |

| Installation Method | DIN‑rail or panel mounting inside an industrial control cabinet |

| Engineering Software | IndraWorks (IEC 61131‑3, motion libraries) |

Application Fields

This controller is well‑suited for discrete manufacturing and motion‑centric equipment. Typical uses include:

- Packaging and converting machines needing synchronized axes and camming

- Material handling, gantries, and palletizing with coordinated servo control

- Assembly automation and press applications requiring deterministic timing

- Machine tools and woodworking lines where motion loops must stay tight

- Intralogistics modules (sorters, shuttles) integrating drives and distributed I/O

A packaging OEM shared that switching to a CML40‑series controller with SERCOS‑based drives shortened their changeover time by about 20%—mostly because the motion profiles and I/O diagnostics live in one toolchain. That’s pretty typical when moving from a split PLC + motion card setup.

Advantages & Value

- Reliability – Industrial 24 V platform with proven MLC runtime; fewer moving parts than PC‑based systems.

- Compatibility – Works seamlessly with Rexroth IndraDrive families; supports common real‑time Ethernet topologies, which simplifies mixed‑vendor plants.

- Engineering efficiency – One project environment (IndraWorks) for PLC logic, motion, and diagnostics—typically cuts commissioning time.

- Lifecycle cost – Modular I/O and scalable licenses mean you only pay for what you need; spare‑part strategy is straightforward.

- Support – Global Rexroth service footprint, plus remote diagnostics over engineering Ethernet.

Installation & Maintenance

- Cabinet & environment – Install in a closed control cabinet (IP54 or better). Keep ambient 0…+50 °C, non‑condensing, with adequate ventilation or fan assistance.

- Power & grounding – 24 V DC supply with proper protective earth. Isolate noisy loads; use separate 24 V feeds for logic vs. actuators where possible.

- Wiring – Use shielded cables for real‑time Ethernet. Maintain bend radius and segregate high‑voltage from signal lines to reduce EMI.

- Networking – Configure real‑time Ethernet master (e.g., SERCOS/EtherCAT) as per licensed option. Fixed IP for engineering port simplifies service.

- Routine maintenance – Back up the project in IndraWorks, log drive and controller diagnostics, clean cabinet filters, and review firmware/patches during planned downtime.

- Spare strategy – Keep one pre‑imaged controller on the shelf; it typically shortens recovery to under an hour in many cases.

Quality & Certifications

- CE conformity (EMC and LVD for control equipment)

- UL/cUL recognition for North American panels (NA variant typically aligned)

- RoHS compliance

- Manufacturer warranty: 12 months from delivery (365 days)

Notes on Options & Compatibility

Certain interfaces and fieldbus masters on the CML40.2 platform are license‑dependent. If you’re targeting a specific drive family (e.g., Rexroth IndraDrive over SERCOS III) or a particular remote I/O stack, share that upfront and we’ll confirm the exact firmware option set for CML40.2‑SP‑330‑NA‑NNNN‑NW.

Reviews

There are no reviews yet.