Description

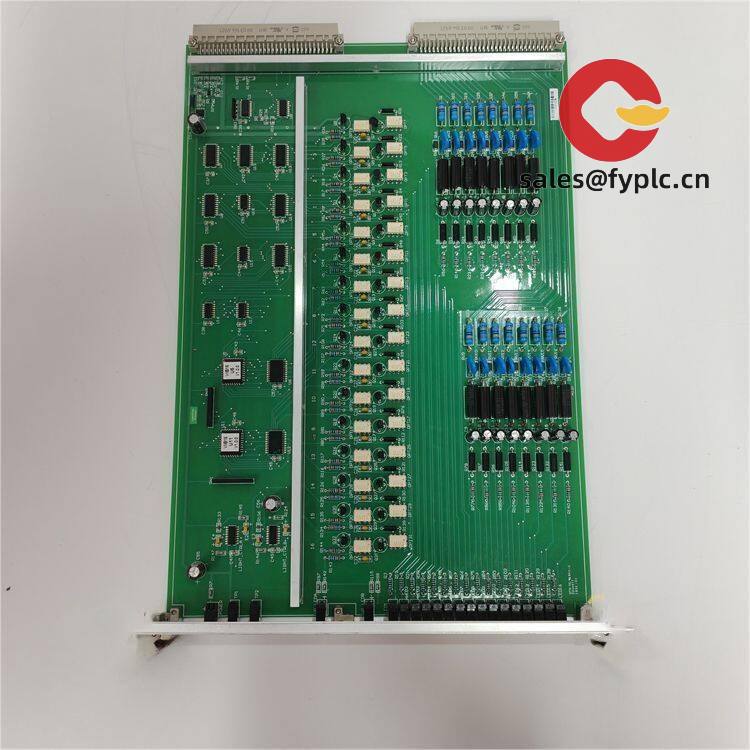

ALSTOM VIIB16-C-12011-105-00 – 16‑Channel Binary Input Module for Alstom Control Racks

The ALSTOM VIIB16-C-12011-105-00 is a 16‑point binary input board designed for legacy Alstom control systems. From my experience, it’s typically used to bring dry/wet contact status signals into the rack—things like limit switches, pressure switches, relay contacts, and permissives in power and process applications. You might notice that the part code suggests a “B16” input density, and that lines up with how it’s deployed in the field: dense, reliable contact monitoring with straightforward diagnostics for maintenance.

Our Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- 16-channel binary inputs – Suitable for consolidating field contacts into a single rack slot; helpful where panel space is tight.

- Wet or dry contact compatibility – In many cases, the board handles 24 VDC “wet” signals or dry contacts depending on wiring practice.

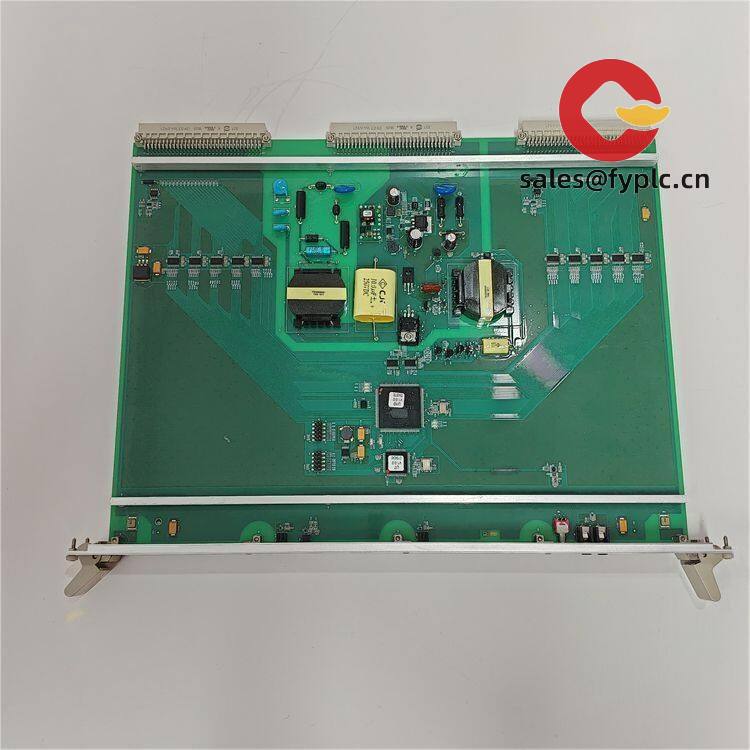

- Backplane-powered – Draws low power from the control rack backplane; no separate PSU required for the board itself.

- Status LEDs and onboard diagnostics – Typically allows quick channel checks during commissioning and troubleshooting.

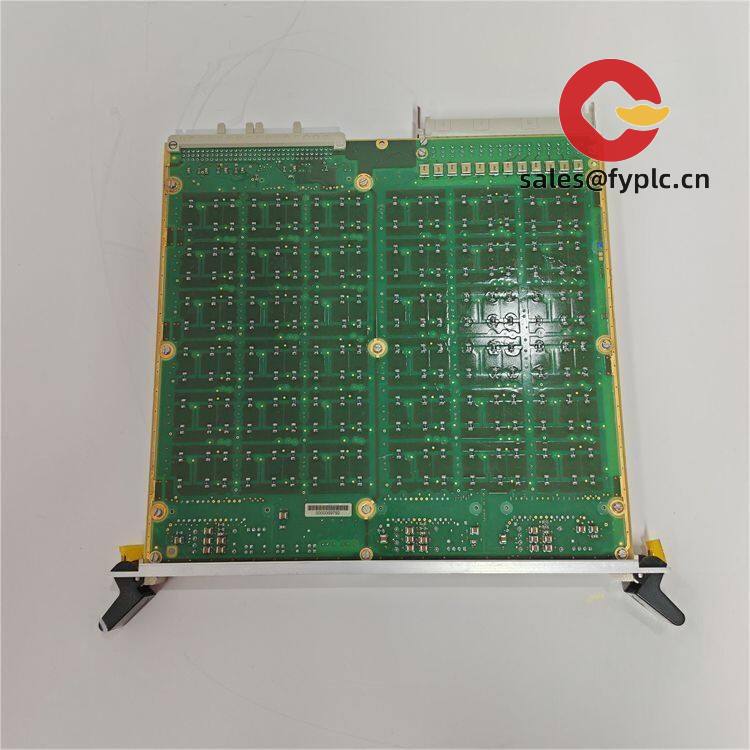

- Form-fit replacement – Designed to drop into existing Alstom racks, minimizing downtime for MRO teams.

- Industrial EMC design – Appears to be built for noisy environments, helping reduce nuisance trips from electrical interference.

Technical Specifications

| Brand / Model | ALSTOM VIIB16-C-12011-105-00 |

| HS Code | 8538.90 (Parts for electrical control apparatus) |

| Power Requirements | Backplane-powered; typically 5 VDC, <5 W (varies by rack/backplane) |

| Dimensions & Weight | Plug-in rack module; Eurocard-style depth (~160 mm typical); approx 0.3–0.5 kg |

| Operating Temperature | 0 to +55 °C (typical for Alstom rack I/O) |

| Signal I/O Types | 16× digital inputs; 24 VDC nominal wet/dry contact capability (depending on wiring and revision) |

| Communication Interface | Proprietary Alstom rack backplane bus |

| Installation Method | Plug-in to Alstom I/O rack; field wiring via front connector/terminal (as per rack standard) |

Application Fields

This board is commonly deployed wherever Alstom legacy control racks are still running. Typical sites include power generation (steam/gas turbines, balance‑of‑plant), utilities and substations, and process machinery where hardwired interlocks are preferred. A maintenance engineer might use it to marshal:

- Motor/valve permissives and limit switches

- Pressure, level, and temperature switch contacts

- Trip circuits and status from protection relays

- Panel pushbuttons and selector switches

Advantages & Value

- Fast replacement – Form/fit compatibility usually means no rewiring or software changes, saving outage time.

- Lower risk – Staying within the original rack ecosystem preserves validated safety logic and IO mapping.

- Lifecycle efficiency – Extends service life of existing Alstom controls without a full system migration.

- Technical backing – We help verify revision compatibility and field wiring assumptions before shipment.

Installation & Maintenance

- Cabinet & environment – Install in a clean, dry control cabinet with adequate ventilation. Keep away from high‑current cabling to reduce EMI.

- Rack & grounding – Use the matching Alstom rack/backplane; verify chassis ground and shield terminations are consistent across the panel.

- Wiring practice – For 24 VDC wet contacts, group commons and use ferrules. For dry contacts, confirm the board’s biasing method (source/sink) before field connection.

- ESD handling – Treat as an ESD‑sensitive PCB; insert and remove with power down unless the manufacturer explicitly permits hot‑swap.

- Routine checks – Periodically verify channel status with LEDs or test points, clean dust with dry air, and re‑torque terminal screws. Document firmware/hardware revisions if applicable.

- Commissioning tip – Map each input to the control logic and simulate state changes to confirm debouncing and alarm behavior.

Quality & Certifications

- Typically manufactured under ISO 9001 quality systems

- CE conformity expected for industrial EMC in most cases

- RoHS status may depend on hardware revision and production year

- Warranty: 12 months (365 days) from delivery

Related/Supporting Components

To streamline installation, teams typically pair this module with:

- Matching Alstom I/O rack/backplane and front terminal connector

- 24 VDC field power distribution with fused commons for wet contacts

- Shielded multi-core signal cable and labeled ferrules for marshaling

One thing I appreciate is how this board fits upgrade paths—if you’re phasing equipment, it lets you stabilize the I/O side first, then address controllers later. If you want, share your rack part number or a snapshot of the terminal layout; we can double‑check the VIIB16-C-12011-105-00 revision against your wiring and confirm the delivery window.

Reviews

There are no reviews yet.