Description

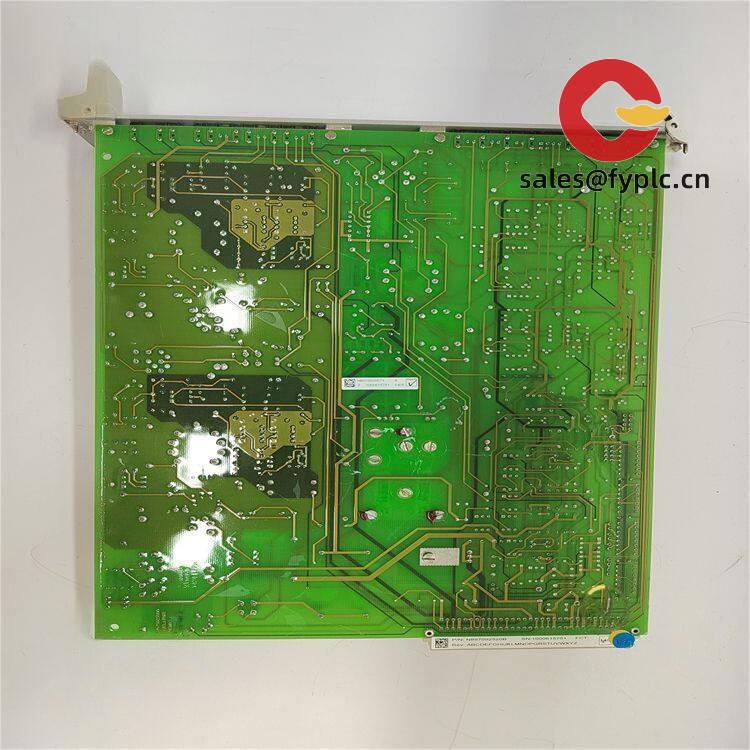

ALSTOM N897066510E / N897066010M AOVD (N897066000A) – Analog Output Voltage Driver Module for rail and industrial control racks

From my experience, the “AOVD” designation on ALSTOM boards typically points to an Analog Output Voltage Driver used in traction, wayside, or process-control cabinets. The part numbers N897066510E, N897066010M, and N897066000A appear to be closely related within the same AOVD board family—often reflecting revision or build variants. In many cases it’s a drop‑in replacement for legacy racks where a stable 0–10 V reference or actuator control is needed without reworking the backplane.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery time: 1 week if in stock, no more than one month at the latest

- Payment terms: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Analog voltage output (0–10 V) – Typically used to drive converters, actuators, or reference channels in ALSTOM control racks.

- Backplane-integrated – Connects via the native ALSTOM rack/bus, so field rewiring is usually minimal.

- Revision-compatible part numbers – N897066510E, N897066010M, and N897066000A are commonly supplied as compatible build variants within the AOVD family.

- Stable output under vibration – Designed for railway and industrial environments where vibration and temperature swings are common.

- Service-friendly – Plug-in card format for quick swap during maintenance windows, keeping downtime low.

Model & Compatibility Notes

You might notice these three identifiers used together on refurbishment lists or MRO kits: N897066510E (later build), N897066010M (earlier build), and N897066000A (often cited with the AOVD functional name). In most cases, they sit in the same functional slot of ALSTOM racks—still, we typically verify the rack code and backplane pinout before shipping to avoid any mismatch on site.

Technical Specifications

| Brand / Model | ALSTOM – N897066510E / N897066010M – AOVD (N897066000A) |

| HS Code | 853890 (Parts suitable for use with industrial control apparatus) |

| Power Requirements | 24 VDC nominal (typical control rack supply) |

| Signal Input/Output Types | Analog voltage output up to 10 V; status via rack/backplane signals (exact channel count per revision) |

| Communication Interfaces | Proprietary backplane interface to ALSTOM rack; no external fieldbus on front panel in most cases |

| Dimensions & Weight | Approx. 100 × 160 mm (3U Eurocard style); ~0.25 kg |

| Operating Temperature | –25 °C to +70 °C (typical for this series; verify per revision) |

| Installation Method | Plug‑in card for ALSTOM control rack; front connector/backplane mating |

Application Fields

- Traction and propulsion cabinets needing stable analog references for control loops.

- Wayside signaling or substation auxiliary systems where 0–10 V control is standard.

- Industrial retrofits in mixed-vintage ALSTOM racks to keep legacy interfaces running.

A maintenance lead from a metro operator told us the AOVD swap “took under 15 minutes during a night shift,” and the line returned to service without parameter changes. That seems to be typical when the rack code and firmware set match.

Advantages & Value

- Reliable compatibility – Built for ALSTOM racks, so integration risk is low compared with third‑party boards.

- Lower downtime – Fast, plug‑in replacement minimizes service disruptions.

- Lifecycle support – We typically cross-check rack codes and firmware notes before shipment to reduce surprises on site.

- Cost control – Keeping the original rack architecture avoids costly re-engineering.

Installation & Maintenance

- Mount in a clean, ventilated cabinet; follow the rack’s specified slot and keying. Keep ambient within the stated range.

- Use 24 VDC supply with proper grounding; check ripple and polarity before insertion.

- Observe ESD practices; de‑energize the rack before card removal/insertion unless hot‑swap is explicitly allowed by the rack manual.

- If the board has calibration trim or jumpers, record settings during replacement to match the outgoing unit.

- Routine checks: annual connector inspection, dust removal with dry air, and verification of analog output accuracy against a known reference.

Quality & Certifications

- Manufactured under ISO 9001 quality systems (typical for ALSTOM suppliers).

- CE and RoHS conformity in most cases; detailed CoC/DoC available per batch or revision upon request.

- 365‑day warranty coverage.

Reviews

There are no reviews yet.