Description

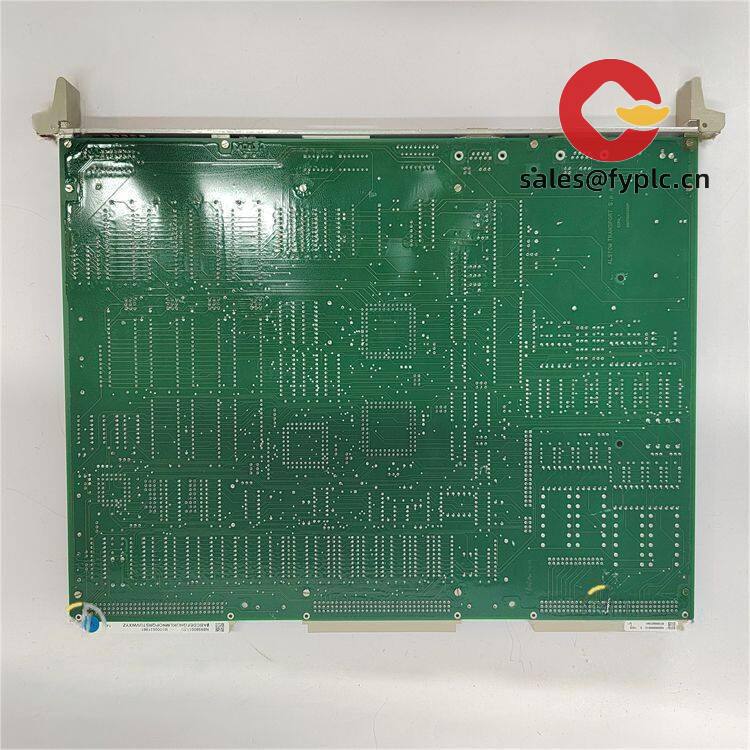

ALSTOM ECPU-1 (N895600512D / N895600051C / N895600200Q) – Central Processor Module for ALSTOM Control Racks

The ALSTOM ECPU-1 is the central processing module used in a range of legacy and current ALSTOM industrial control platforms. The part codes N895600512D, N895600051C, and N895600200Q are common hardware revisions and compatible spares for the same CPU board family. From my experience, this module is typically found in power plant excitation and turbine/generator control panels, as well as heavy-process lines where long service life and predictable cycle times matter more than flashy features. You might notice that maintenance teams value it for straightforward field replacement and stable operation once it’s in the rack and configured.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: typically 1 week if in stock; no more than 1 month at the latest

- Payment: 50% advance payment; balance prior to delivery

- Express delivery: FedEx, UPS, DHL

- Each unit is function-tested prior to shipment, with test report available on request

Key Features

- Rack-mounted ALSTOM CPU module – Fits designated CPU slot in ALSTOM control chassis, powered via the system backplane.

- Revision-compatible part numbers – N895600512D / N895600051C / N895600200Q commonly serve as direct replacements within the ECPU-1 family.

- Deterministic control cycle – Stable scan times for predictable sequencing; ideal for excitation control and turbine auxiliary logic.

- Built-in diagnostics – Front-panel indicators and self-check routines help technicians pinpoint faults faster.

- Non-volatile configuration storage – Preserves application data across power cycles for minimal downtime.

- Serviceability – Field-replaceable in minutes; typically requires planned shutdown unless a redundant architecture is installed.

- Backplane-centric I/O – No direct field I/O on the CPU; it supervises I/O cards via the chassis bus for cleaner wiring and easier segregation.

Technical Specifications

| Brand / Model | ALSTOM ECPU-1 |

| Associated Part Numbers | N895600512D, N895600051C, N895600200Q |

| Product Type | Rack-mounted CPU board for ALSTOM control systems |

| HS Code | 8537.10 (Programmable control panels and modules) |

| Power Requirements | Supplied via system backplane (no separate external supply) |

| Signal I/O Types | CPU-level control; communicates with I/O modules over the backplane (no direct field I/O on the CPU) |

| Communication Interfaces | Backplane bus; front-panel service port availability and type may vary by revision |

| Installation Method | Slide-in card; fits the designated CPU slot in ALSTOM chassis with card guides and locking hardware |

Application Fields

This ECPU-1 typically serves in:

- Power generation: excitation control, turbine auxiliary systems, and balance-of-plant logic

- Heavy process industries: steel, cement, paper, and chemicals where continuous duty and stable scan times matter

- Oil & gas and petrochem: unit interlocks, permissives, and protective sequences

- Infrastructure and utilities: water treatment and district energy control rooms using ALSTOM panels

Feedback from a maintenance supervisor at a combined-cycle site: “We swapped the ECPU-1 (N895600051C) in under 20 minutes, loaded the project file, and were back online before the next shift—no nuisance trips.”

Advantages & Value

- Reliability in long-running plants – Proven stability in cabinet environments; low drift in control timing.

- Form-fit-function compatibility – Drop-in replacement for specified ALSTOM racks using the ECPU-1 CPU slot.

- Lower risk vs. system migration – Extends system life without immediate DCS/PLC replacement costs.

- Configuration continuity – Retains application logic; typically requires only a straightforward download and verification.

- Technical backing – Pre-shipment test, firmware/version checks upon request, and guidance on handling configuration files.

Installation & Maintenance

- Panel environment – Install in a clean, ventilated control cabinet; maintain adequate airflow and avoid heat sources.

- ESD handling – Use a grounded wrist strap; avoid touching edge connectors and components.

- Slot alignment – Insert along the card guides; lock fully to ensure proper backplane engagement.

- Power-down procedure – Unless you have a validated redundant setup, plan a controlled shutdown before replacement.

- Configuration – Back up the existing project; verify firmware and application compatibility with the target revision (N895600512D / N895600051C / N895600200Q).

- Routine care – Periodically clean connectors with approved contact cleaner, check cabinet filters, and archive configuration after any change.

- Firmware policy – Where applicable, align firmware with your fleet standard; document changes in the site maintenance log.

Quality & Certifications

- Manufacturer production under established quality systems (commonly ISO 9001 for industrial electronics)

- EMC/CE practices typical for cabinet-installed industrial control modules

- Units are inspected and tested prior to shipment; functional report available

- Warranty coverage: 365 days

Supporting components often paired with ECPU-1 in ALSTOM racks include the system power supply module, digital/analog I/O cards, and communication gateway boards. If you’re planning a like-for-like replacement or a staged upgrade, we can align the CPU revision with your existing backplane and I/O set to reduce commissioning time.

Reviews

There are no reviews yet.