Description

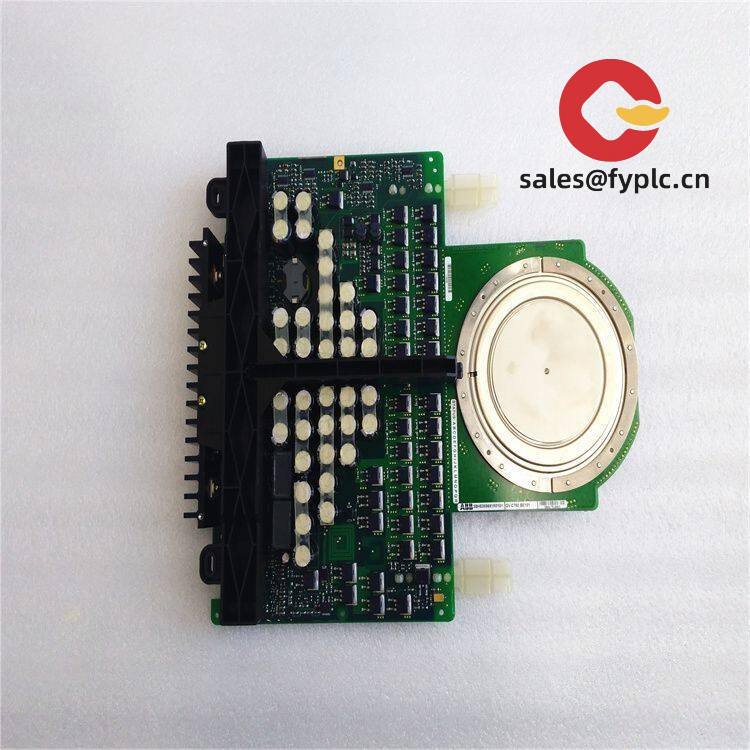

ABB 5SHX 3545L0016 + 3BHB020720R0002 – High‑Power IGCT with Fiber-Optic Gate Unit for Medium-Voltage Drives

The ABB 5SHX 3545L0016 paired with the 3BHB020720R0002 gate unit is a proven combination for high-reliability switching in medium-voltage converters. From my experience, this set is typically selected for retrofit or maintenance of large industrial drives and static power converters where stable turn-off behavior and predictable thermal performance really matter. You might notice that many maintenance teams prefer keeping the IGCT and its matching gate driver together to minimize commissioning risk and downtime.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in-stock items; no more than one month at the latest

- Payment: 50% advance payment, full payment before delivery

- Express delivery: FedEx, UPS, DHL

Key Features

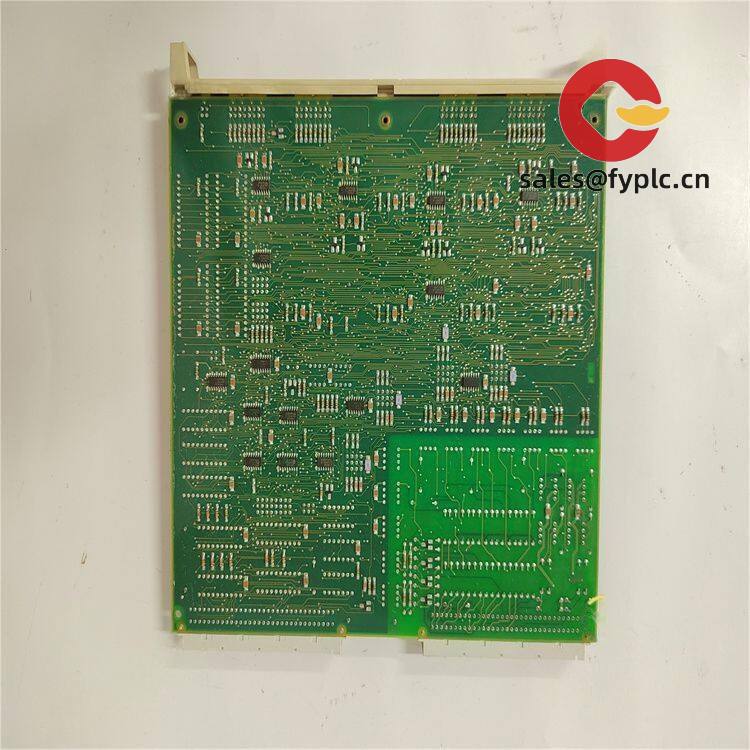

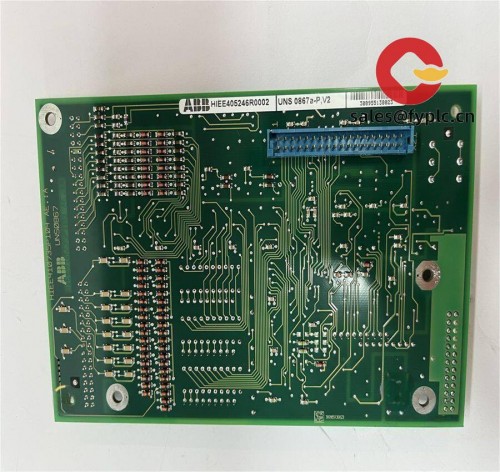

- Matched IGCT + Gate Unit – The 5SHX 3545L0016 (press-pack IGCT) and 3BHB020720R0002 (fiber‑optic gate driver) are commonly used together in ABB medium‑voltage converter stacks to ensure reliable turn-on/turn-off dynamics.

- High voltage/current capability – The 5SHX 35xx family generally targets multi‑kA, multi‑kV switching. This seems to be the go-to choice when you need robust margins in 3–6 kV DC link environments.

- Fiber‑optic triggering – Gate commands and status typically run over fiber, reducing electrical noise issues in high dv/dt cabinets.

- Press‑pack reliability – Clamped press‑pack design tolerates thermal cycling and, in many cases, offers predictable end‑of‑life compared to plastic modules.

- Service‑friendly – Keeping a matched device/driver pair on the shelf shortens outage time; technicians often report quicker ramp‑up after replacement.

- Designed for MV drives and converters – Typical in heavy industry: fans, pumps, compressors, marine propulsion and grid converters where availability is non‑negotiable.

Technical Specifications

| Brand / Model | ABB 5SHX 3545L0016 (IGCT) + ABB 3BHB020720R0002 (Gate Unit) |

| HS Code | IGCT typically 8541.29 (Thyristors, diacs and triacs). Gate unit is often classified under 8537/8543 depending on configuration and shipment. |

| Power Requirements | Gate unit supply: 24 VDC nominal (typical); IGCT is passive (no direct supply). |

| Dimensions & Weight | IGCT press‑pack, approx. Ø130–140 mm, height ~26–30 mm; mass ~1–1.5 kg (typical for 4.5 kV / 3.5 kA class). Gate unit: compact driver board/enclosure, cabinet‑mountable. |

| Operating Temperature | IGCT junction typically up to 125°C; gate unit ambient usually 0…50°C (follow ABB datasheet for exact limits). |

| Signal I/O | Fiber‑optic command Rx/Tx for firing and status; low‑voltage auxiliary terminals for power and interlocks (typical). |

| Communication Interfaces | Optical links (trigger/status). No fieldbus on the IGCT itself; integration handled by the drive control. |

| Installation Method | Press‑pack clamped between heat‑sinks with specified force; gate unit mounted near device with fiber routing and shielded auxiliaries. Suitable for forced‑air or liquid‑cooled stacks. |

Application Fields

This combination is widely used in medium‑voltage drives and converters, including:

- Industrial MV drives (fans, pumps, compressors) in oil & gas, mining, cement, and metals

- Power quality and grid converters (STATCOMs, SVC upgrades, large rectifier/inverter bridges)

- Marine propulsion and rolling stock traction converters

- Large wind turbine converters and test benches where fault‑tolerant turn‑off is critical

Advantages & Value

- Reliability under stress – Press‑pack IGCTs typically handle repetitive surge conditions better than plastic modules; field teams report stable thermal behavior over long duty cycles.

- Compatibility – Frequently used in ABB MV platforms; keeping the 3BHB020720R0002 driver with the 5SHX device helps maintain timing and protection margins.

- Cost control – A like‑for‑like swap reduces engineering time, requalification, and commissioning retries—especially valuable in critical production windows.

- Technical support – We typically assist with part verification against your existing stack drawings, helping avoid mismatches in clamp force, cooling, or fiber routing.

Installation & Maintenance

- Cabinet & environment – Mount in an IP‑rated cabinet with clean airflow. Keep humidity controlled and avoid conductive dust. Provide adequate creepage/clearance for MV sections.

- Clamping & thermal path – Use ABB‑specified clamp force and parallelism; re‑lap or replace heat‑sink interfaces if surfaces are scratched. Apply the recommended thermal interface material sparingly and evenly.

- Wiring & fibers – Route fiber‑optic pairs with gentle bends; segregate auxiliary 24 V lines from high‑dv/dt paths. Verify polarity of optical Tx/Rx before energization.

- Safety – Lockout/tagout, discharge DC links fully, and observe ESD procedures when handling the gate unit. Confirm interlock chains before first firing.

- Routine checks – Periodically inspect clamp force, connector tightness, and cooling performance. Clean filters, check fan or coolant flow, and update gate unit firmware if applicable to your drive revision.

- Commissioning tips – Start with reduced load, confirm gate timing and status via the drive tool, then ramp to nominal current while monitoring device temperature.

Quality & Certifications

- Manufactured under ISO 9001 quality systems (ABB production)

- RoHS compliant semiconductor device; gate unit typically CE marked for EMC/safety where applicable

- 365‑day warranty (replacement or repair subject to standard terms)

Quick customer note: a maintenance manager at a cement plant told us their swap to a fresh 5SHX 3545L0016 + 3BHB020720R0002 pair cut their restart time by half compared with mixing old/new parts. That aligns with what we typically see during planned shutdowns.

Reviews

There are no reviews yet.