Description

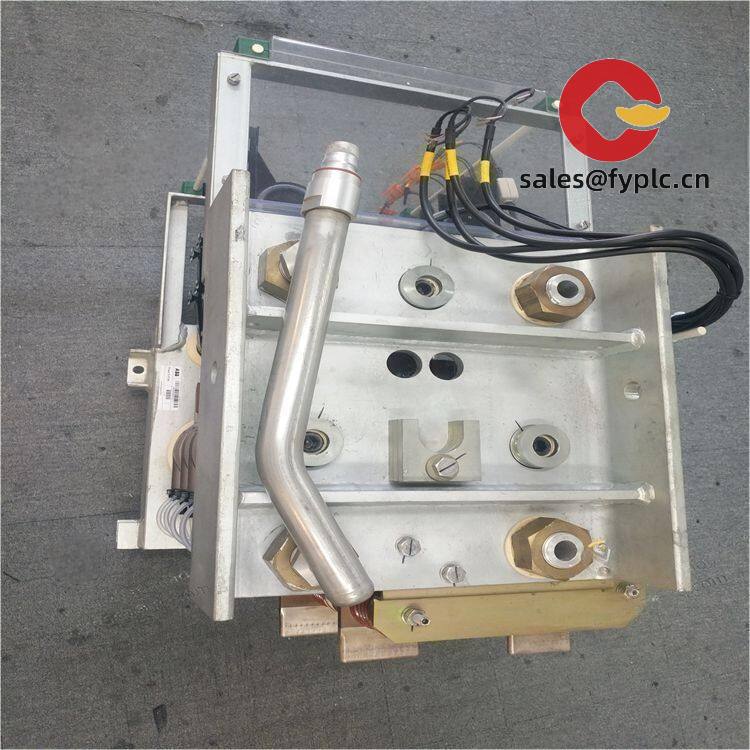

ABB 5SHY3545L0014-3BHE023784R0001 – IGCT Gate Unit for Medium-Voltage Drive Stacks

The ABB 5SHY3545L0014-3BHE023784R0001 is a genuine ABB gate unit designed for controlling IGCT devices in medium-voltage power converter stacks. In many cases it’s used as a like-for-like spare in ABB MV drives (e.g., ACS1000/ACS3000/ACS5000 families) and high-power static converters. From my experience, plants choose this part when they need stable gate drive performance, clean fiber-optic triggering, and reliable status feedback without requalifying the whole stack.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment, full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- IGCT-optimized gate drive – Provides the fast, high-current gate pulse and protection logic required by ABB IGCT stacks.

- Fiber‑optic control link – Typically Rx/Tx optical triggering for noise-immune firing in MV environments.

- Status and interlock feedback – Fault/status relay contact output to the converter’s protection chain.

- 24 VDC auxiliary supply – Common plant control voltage, easing retrofit and service.

- Form-fit replacement – Matches the mounting footprint used on many ABB IGCT stacks, which usually keeps downtime low.

- Proven in MV drives – Seen widely in ABB ACS-series MV drives and other high-power static converters.

Technical Specifications

| Brand / Model | ABB 5SHY3545L0014-3BHE023784R0001 (IGCT Gate Unit) |

| HS Code | 8504.90 (Parts suitable for static converters) |

| Power Requirements | 24 VDC auxiliary (typically 18–30 VDC range), power draw typically <10 W |

| Operating Temperature | Typically 0 to +70 °C (storage often −40 to +85 °C) |

| Signal I/O Types | Fiber‑optic Rx/Tx for firing; gate drive output to IGCT; fault/status relay contact; 24 VDC power terminal |

| Communication Interfaces | Fiber‑optic control link (proprietary ABB drive interface) |

| Installation Method | Panel/stack mounting on the IGCT assembly; screw‑fastened with plug‑in power and signal connectors |

| Dimensions & Weight | Typical ABB gate-unit footprint (approx. 170 × 120 × 35 mm); ~0.4 kg |

Values above reflect typical characteristics for this ABB gate-unit series. For a specific project BOM, matching the exact revision is recommended.

Application Fields

You might notice this model deployed in:

- Medium-voltage drives (e.g., pump, fan, compressor duty in oil & gas, mining, cement, steel)

- Reactive power compensation and STATCOM systems

- High-power motor test benches and large rolling mills

- Wind and marine high-power converter stacks using ABB IGCT technology

A maintenance lead at a cement plant told us their team swapped this gate unit on an ACS1000 stack during a planned stop and were back online in under two hours—no parameter changes, just clean fiber connections and a quick interlock check.

Advantages & Value

- Reliability – ABB’s IGCT drive chain is robust against electrical noise; fiber control helps avoid nuisance misfires.

- Compatibility – From my experience, 5SHY-series gate units align well with ABB IGCT types (e.g., 5SNG/5SHX families) used in ACS MV platforms.

- Cost savings – Form-fit replacement reduces engineering time and shortens outages compared with redesigning the gate stage.

- Technical support – Clear wiring, fiber routing guidance, and torque specs typically available from ABB service notes.

Installation & Maintenance

- Cabinet standards – Install in a clean, dry MV drive cabinet with adequate ventilation; maintain creepage/clearance around HV parts.

- Wiring & fiber – Use clean 24 VDC with proper grounding; route fiber‑optic cables with minimum bend radius and keep connectors free of dust.

- Mounting – Fasten to the IGCT stack or panel points per torque recommendations; verify connector seating before energizing.

- Safety – Lockout/tagout, wait for DC link discharge, and follow ESD precautions. IGCT stacks retain charge longer than expected in some cases.

- Routine checks – Inspect fiber ends, confirm 24 V supply stability, review interlock relay operation, and note any revision alignment across phases.

Quality & Certifications

- Manufactured under ABB quality systems (ISO 9001 typical)

- CE conformity and RoHS compliance are commonly applicable for this series

- Manufacturer’s warranty practices apply; seller warranty: 365 days

One thing I appreciate is how predictable installation tends to be: match the 3BHE order code on your existing unit, keep fiber paths clean, and the swap usually goes smoothly. If you need a quick check against your drive typeplate or stack drawing, share the BOM and we’ll verify compatibility before shipment.

Reviews

There are no reviews yet.