Description

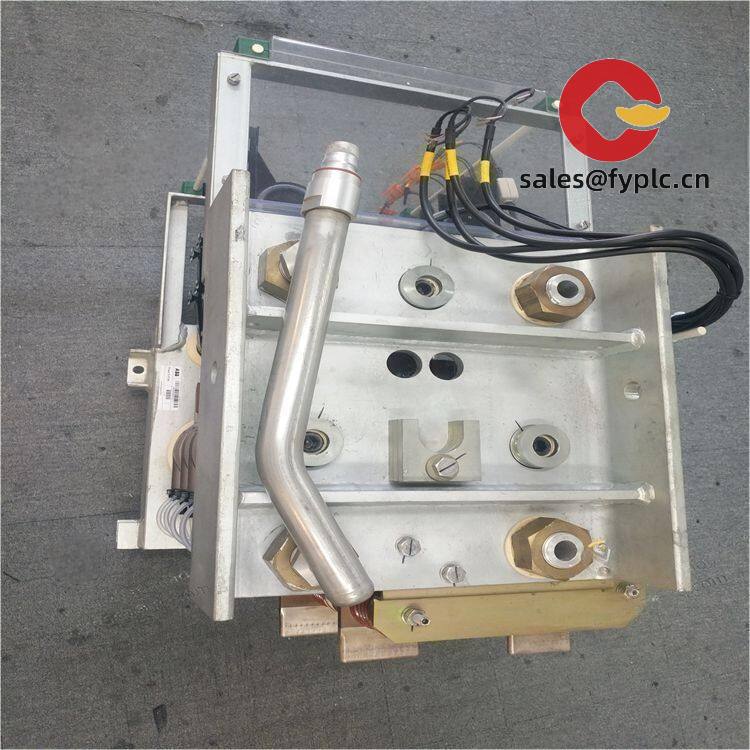

ABB 5SHX1445H0002 (Order code 3BHL000387P0101) – IGCT Gate Unit for High-Power Converter Stacks

The ABB 5SHX1445H0002 (3BHL000387P0101) is a dedicated IGCT gate unit designed to drive ABB’s 4.5 kV class IGCTs in medium-voltage drives, STATCOM/FACTS, and heavy industrial power converters. From my experience, this gate unit is typically used as a drop-in service spare or a one-to-one pairing in existing IGCT stacks, keeping system behavior consistent without re-qualification headaches. You might notice that it integrates high current turn-off capability, fiber‑optic triggering, and protection functions in a compact, direct-mount form factor.

Our Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than 1 month at the latest

- Payment: 50% advance payment, full payment prior to delivery

- Express options: FedEx, UPS, DHL

Key Features

- Purpose‑built IGCT drive – Engineered to drive ABB 4.5 kV class IGCT devices with the required peak gate current and low inductance path.

- Fiber‑optic triggering – Optical Rx/Tx interfaces provide excellent noise immunity in high dV/dt environments and simplify stack insulation coordination.

- Integrated protection – Typically includes desaturation/overcurrent monitoring and status feedback to help protect the device during abnormal events.

- 24 VDC industrial supply – Runs from a standard 24 VDC control supply, which in many cases simplifies retrofits or field replacements.

- Direct‑mount ring design – Fast, repeatable installation onto the press‑pack IGCT, supporting consistent clamping geometry and maintenance efficiency.

- Proven in demanding duty – Common in medium‑voltage drives, STATCOM/FACTS, and large converters where uptime and thermal robustness matter.

- Service friendly – One thing I appreciate is the straightforward replacement process: swap the unit, connect fiber and supply, and you’re back in service quickly.

Technical Specifications

| Brand / Model | ABB 5SHX1445H0002 (Order code 3BHL000387P0101) |

| Product Type | IGCT Gate Unit (4.5 kV class) |

| Compatibility | Selected ABB 5SHY 4.5 kV IGCT families; verify pairing against your IGCT part number |

| HS Code | 8504.90 (Parts for static converters) |

| Power Requirements | 24 VDC nominal control supply (typical for ABB IGCT gate units) |

| Signal I/O Types | Fiber‑optic trigger/feedback; power interface to IGCT gate/cathode |

| Communication Interfaces | Optical link only; no fieldbus |

| Installation Method | Direct mounting on press‑pack IGCT; fiber routing to control rack |

| Operating Temperature | Typically −40°C to +85°C (confirm exact limit by revision/datasheet) |

Application Fields

Commonly deployed in:

- Medium‑voltage drives for cement, steel, mining, and oil & gas compressors

- STATCOM/FACTS and reactive power compensation systems

- Marine propulsion and large propulsion inverters

- High‑power wind turbine converters and test benches

- Industrial UPS and energy storage converters

Advantages & Value

- Reliability under stress – Designed for the high di/dt and thermal cycling seen in MV stacks, which, in many cases, reduces nuisance trips.

- Compatibility assurance – Matching gate parameters for ABB IGCTs helps keep switching behavior predictable and safe.

- Lower retrofit risk – When replacing like‑for‑like, there’s no need to retune turn‑off energy or revalidate protection thresholds.

- Service continuity – Quick swap‑out and fiber connections shorten outage windows and reduce crane time on large stacks.

- Technical support – Access to pairing guidance with common IGCTs (e.g., 5SHY 4.5 kV series) and stack checklists.

A maintenance engineer from a cement plant told us the unit “dropped straight into our STATCOM cell; fiber links latched, and we were back online before shift change.” That seems to be a typical experience when the pairing is confirmed in advance.

Installation & Maintenance

- Mounting – Install directly onto the designated press‑pack IGCT. Ensure correct clamping procedure/torque per ABB’s stack drawing.

- Environment – Use in a clean, dry, ventilated cabinet. Maintain adequate creepage/clearance and avoid conductive dust.

- Wiring/Fiber – Supply from a regulated 24 VDC source. Route duplex fiber‑optic links with gentle bend radius; verify Rx/Tx polarity.

- Safety – Lock‑out/tag‑out the DC link. Discharge capacitors fully before handling. Observe ESD precautions.

- Routine checks – Inspect fiber ends, connectors, and supply terminals during outages. Verify device temperatures and alarms. Replace if optical loss or intermittent faults are observed.

- Documentation – Confirm the gate unit revision matches your IGCT part and stack design notes; update maintenance records accordingly.

Quality & Certifications

- Manufacturer quality systems typically aligned with ISO 9001 and ISO 14001

- Conformance with CE and RoHS where applicable for control electronics

- 365‑day warranty from shipment

Note: The 5SHX1445H0002 gate unit is intended to operate with specific ABB IGCT part numbers. If you share your IGCT device code (e.g., a 5SHY 4.5 kV model) and stack details, we’ll verify pairing and delivery from stock or provide the nearest compatible revision.

Reviews

There are no reviews yet.