Description

Allen-Bradley 1746-A10: Reliable Adapter Module for SLC 500 Systems

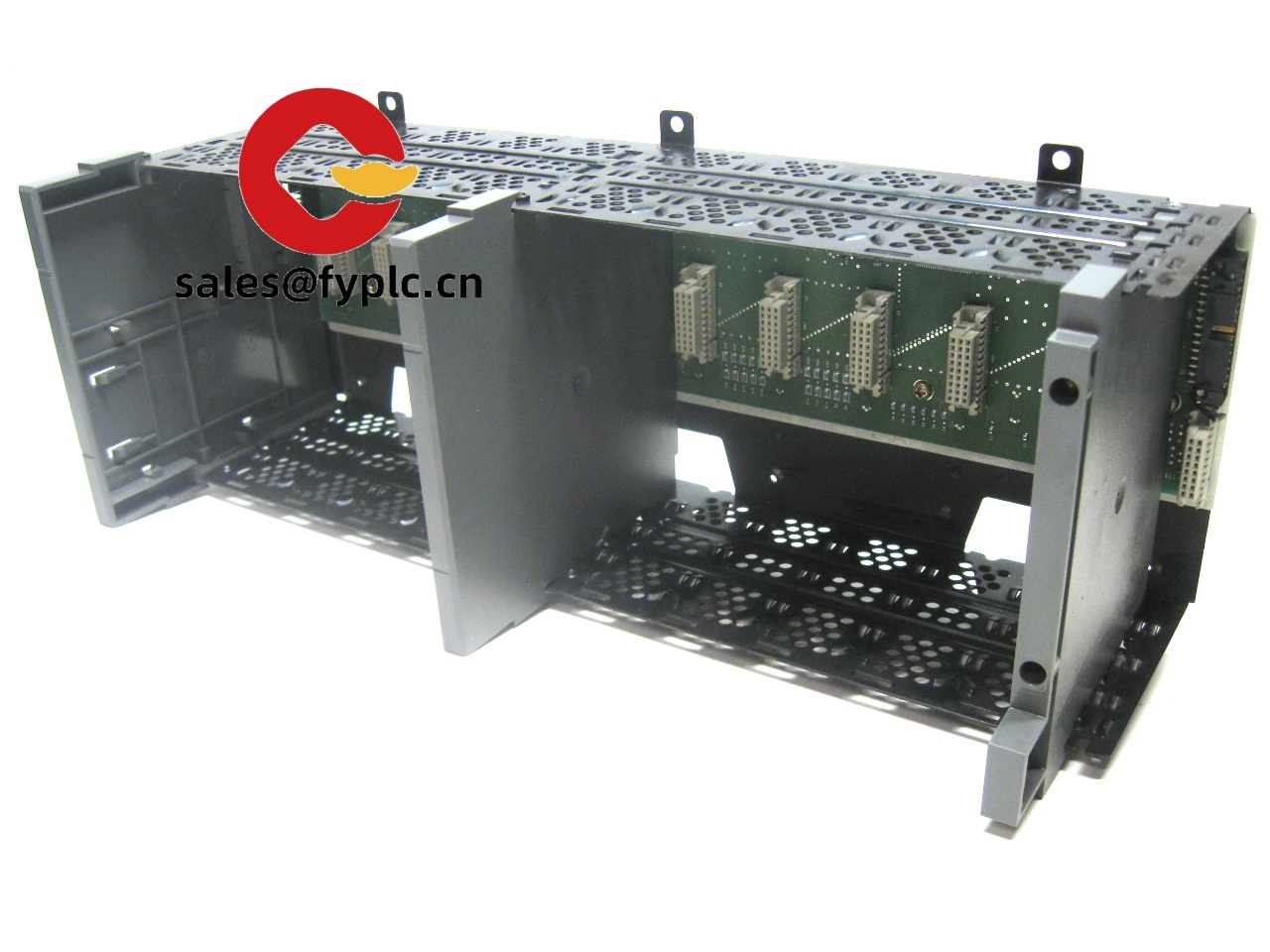

The Allen-Bradley 1746-A10 is a compact yet robust adapter module designed to enhance the connectivity and functionality of SLC 500 systems. From my experience, this adapter seems to be a favorite among engineers who need seamless integration between legacy PLC setups and modern control architectures.

Key Features

- Plug-and-Play Compatibility: Designed specifically for SLC 500 racks, it eliminates complex wiring or configuration issues.

- Compact Design: Its small footprint makes it ideal for installations where space is at a premium.

- Durable Build Quality: The rugged construction ensures reliable performance in demanding industrial environments.

- Hot-Swappable: You can replace or upgrade modules without shutting down the entire system, minimizing downtime.

Technical Specifications

| Specification | Details |

|---|---|

| Brand/Model | Allen-Bradley 1746-A10 |

| HS Code | 85371090 |

| Power Requirements | 5V DC (Backplane Power) |

| Dimensions & Weight | Height: 120mm, Width: 30mm, Depth: 100mm, Weight: 0.3kg |

| Operating Temperature | 0°C to 60°C (32°F to 140°F) |

| Signal Input/Output Types | Digital I/O Support via Compatible Modules |

| Communication Interfaces | Backplane Communication with SLC 500 Chassis |

| Installation Method | Rack-Mounted in SLC 500 System |

Application Fields

This adapter finds its place in industries that rely on SLC 500 systems, such as manufacturing plants, water treatment facilities, and packaging lines. In many cases, it’s used to connect additional modules like analog inputs or specialty controllers, enabling more advanced automation capabilities without replacing the entire setup.

Advantages & Value

One thing I appreciate about the 1746-A10 is how it balances cost-effectiveness with reliability. It allows businesses to extend the life of their existing equipment while adding new functionalities. Additionally, Rockwell Automation’s technical support network provides peace of mind when troubleshooting or upgrading systems. For procurement teams, this means lower upfront costs compared to migrating to newer platforms.

Installation & Maintenance

Installing the 1746-A10 is straightforward—simply slide it into an available slot in your SLC 500 rack. Ensure proper ventilation around the chassis to prevent overheating. Routine maintenance typically involves checking connections and ensuring firmware compatibility during system updates. Calibration isn’t required since it operates passively within the backplane architecture.

Quality & Certifications

The Allen-Bradley 1746-A10 comes with certifications like CE, UL, and RoHS compliance, ensuring safety and environmental responsibility. A standard one-year warranty covers manufacturing defects, though failures are rare given its proven track record in the field.

Order Placement Process and Guarantees

For orders, we require a 50% advance payment, with the remaining balance due before delivery. Delivery times vary depending on stock availability but typically range from one week for in-stock items to no more than one month for special orders. We ship globally using trusted carriers like FedEx, UPS, and DHL. Our warranty period is 365 days, offering you added confidence in your purchase.

Reviews

There are no reviews yet.