Description

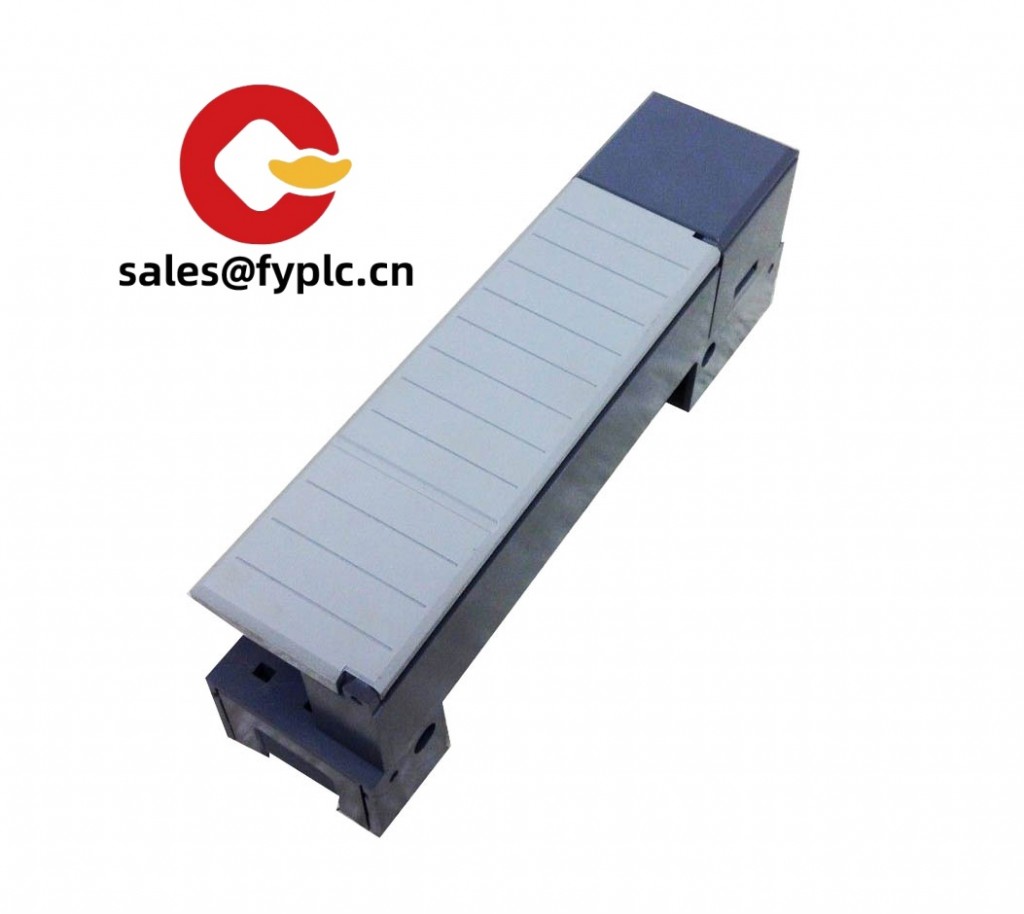

Allen-Bradley 1746-IA16: Reliable Input Module for Industrial Automation

The Allen-Bradley 1746-IA16 is a dependable 16-channel input module designed to streamline data acquisition in PLC-based systems. From my experience, this module seems to be one of the most versatile options for integrating discrete sensors and switches into your automation setup.

Key Features

- 16 Discrete Inputs: Provides reliable signal processing for up to 16 devices, making it ideal for applications with multiple sensor inputs.

- Wide Voltage Range: Supports input voltages from 10-30V DC, offering flexibility across various industrial environments.

- Compact Design: Its slim profile allows for efficient use of cabinet space, which is typically a concern in retrofit projects.

- Diagnostics Support: Built-in diagnostics simplify troubleshooting, reducing downtime during critical operations.

Technical Specifications

| Specification | Details |

|---|---|

| Brand/Model | Allen-Bradley 1746-IA16 |

| HS Code | 85371099 |

| Power Requirements | 10-30V DC |

| Dimensions & Weight | Approx. 120 x 80 x 50 mm; 0.5 kg |

| Operating Temperature | 0°C to 60°C (32°F to 140°F) |

| Signal Input Types | Discrete Inputs (16 channels) |

| Communication Interfaces | Compatible with Allen-Bradley SLC 500 systems |

| Installation Method | DIN rail mounting |

Application Fields

This module shines in industries like manufacturing, packaging, and material handling. You might notice that it’s particularly useful in assembly lines where multiple sensors monitor conveyor belts or robotic arms. In many cases, customers also deploy it in HVAC systems to track equipment status remotely.

Advantages & Value

One thing I appreciate about the 1746-IA16 is its compatibility with existing Allen-Bradley SLC 500 systems, ensuring seamless integration without costly upgrades. Additionally, its robust build quality minimizes replacement costs over time. For procurement teams, the combination of reliability and ease of installation translates into long-term savings.

Installation & Maintenance

For optimal performance, ensure proper ventilation inside the control cabinet to prevent overheating. Wiring should comply with standard electrical practices, using shielded cables if interference is a concern. Routine maintenance includes periodic cleaning of connectors and firmware updates when available through Rockwell Automation tools.

Quality & Certifications

The Allen-Bradley 1746-IA16 holds certifications such as CE, UL, and RoHS compliance, guaranteeing adherence to international safety and environmental standards. It comes with a standard manufacturer’s warranty policy covering defects for one year post-purchase.

Order Placement Process and Guarantees

We offer a streamlined ordering process with a delivery time of just one week for in-stock items, and no more than one month for special orders. A 50% advance payment secures your order, with the balance due before shipment. Express delivery via FedEx, UPS, or DHL ensures timely arrival, backed by our 365-day warranty period.

Reviews

There are no reviews yet.