Description

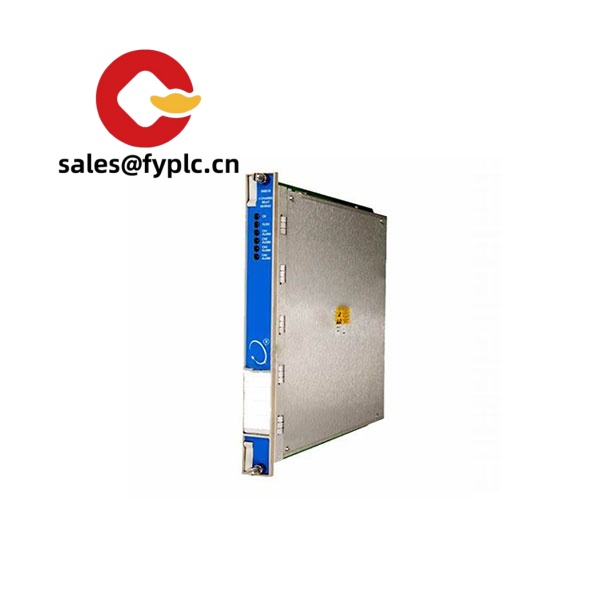

BENTLY 3500-25-01-01-00: Advanced Vibration Monitoring System for Industrial Machinery

If you’re looking to protect critical rotating equipment from unexpected failures, the BENTLY 3500-25-01-01-00 is a reliable solution. This system is designed for continuous vibration monitoring, ensuring machinery operates within safe parameters and helping prevent costly downtime.

Key Features

- High-Precision Vibration Sensors: Delivers accurate readings even in harsh industrial environments, making it ideal for turbines, compressors, and pumps.

- Real-Time Alerts: Provides instant notifications when vibration levels exceed thresholds, allowing operators to take corrective action quickly.

- Modular Design: The system’s flexibility allows for easy expansion or reconfiguration based on changing operational needs.

- User-Friendly Interface: From my experience, the intuitive software simplifies data interpretation, which is particularly helpful for teams with varying technical expertise.

- Reliable Data Logging: Ensures historical data is stored securely, aiding in trend analysis and predictive maintenance planning.

Technical Specifications

| Specification | Details |

|---|---|

| Brand/Model | BENTLY 3500-25-01-01-00 |

| HS Code | 90318090 |

| Power Requirements | 24V DC ±10% |

| Dimensions & Weight | 19″ Rack Mount (4U), ~15kg |

| Operating Temperature | -20°C to +60°C |

| Signal Input/Output Types | Analog Inputs, Relay Outputs |

| Communication Interfaces | Ethernet, Modbus TCP/IP |

| Installation Method | Rack-Mounted |

Application Fields

This system is widely used across industries where reliability is non-negotiable. For instance, in power generation plants, it monitors steam turbine vibrations to avoid catastrophic failures. Similarly, petrochemical facilities rely on it to track compressor health, while manufacturing units use it to safeguard high-speed motors. You might notice that its robust performance makes it especially suitable for environments with high noise levels or extreme temperatures.

Advantages & Value

One thing I appreciate about this model is how seamlessly it integrates into existing control systems. Its compatibility with various PLCs and SCADA platforms reduces integration headaches. Additionally, the modular design translates into long-term cost savings since upgrades don’t require replacing the entire unit. Many clients have mentioned that the availability of spare parts and responsive technical support adds significant value during implementation phases.

Installation & Maintenance

For optimal performance, install the system in a standard 19-inch cabinet with adequate ventilation. Wiring should comply with local electrical codes, and proper grounding is essential to minimize interference. Routine maintenance includes periodic sensor calibration every six months and firmware updates as new versions become available. Cleaning dust filters regularly will also extend the lifespan of internal components.

Quality & Certifications

The BENTLY 3500-25-01-01-00 meets stringent industry standards, holding certifications such as CE, UL, and RoHS compliance. It comes with a one-year manufacturer’s warranty, covering defects in materials and workmanship under normal use conditions. In most cases, extended warranties are negotiable depending on your procurement volume.

Order Placement Process: To secure your order, we require a 50% advance payment, with the balance due before delivery. Delivery times typically range from one week for in-stock items to no more than four weeks for custom configurations. We ship globally via FedEx, UPS, or DHL, ensuring timely and secure deliveries.

Reviews

There are no reviews yet.