Description

Woodward 8200-1310: Precision Control for Industrial Turbines

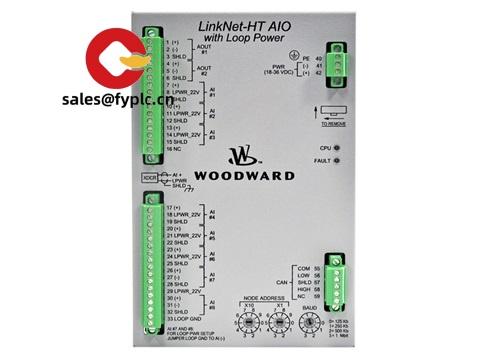

The Woodward 8200-1310 is a robust control module designed to deliver exceptional performance in turbine and engine management systems. From my experience, it seems that operators value its reliability when precision and uptime are non-negotiable.

Key Features

- Advanced Turbine Control: This module ensures accurate speed and load regulation for industrial turbines, making it ideal for power generation applications.

- Real-Time Monitoring: Equipped with diagnostic capabilities, it allows operators to track system health and preempt potential issues before they escalate.

- Flexible Communication Interfaces: Supports Modbus and Ethernet protocols, enabling seamless integration into modern SCADA systems.

- Compact Design: Its space-saving form factor fits easily into existing control cabinets without compromising functionality.

Technical Specifications

| Specification | Details |

|---|---|

| Brand/Model | Woodward / 8200-1310 |

| HS Code | 85371099 |

| Power Requirements | 24V DC (±10%) |

| Dimensions & Weight | 250mm x 150mm x 80mm, 3.5kg |

| Operating Temperature | -20°C to +60°C |

| Signal Input/Output Types | Analog (4-20mA), Digital I/O |

| Communication Interfaces | Modbus RTU, Ethernet/IP |

| Installation Method | DIN Rail or Panel Mount |

Application Fields

The Woodward 8200-1310 finds extensive use in industries where precise control over rotating machinery is critical. You might notice that it’s particularly favored in power plants for gas and steam turbines, as well as in oil and gas facilities managing compressor stations. In many cases, it also supports marine propulsion systems, ensuring smooth operation under varying load conditions.

Advantages & Value

One thing I appreciate is how this model balances cost-effectiveness with high performance. Typically, customers see long-term savings due to reduced downtime and lower maintenance costs. Compatibility with legacy systems means you won’t need a complete overhaul to integrate it, while technical support from Woodward adds another layer of assurance for end users.

Installation & Maintenance

For installation, ensure the control cabinet meets standard NEMA or IP ratings for dust and moisture protection. Adequate ventilation around the unit prevents overheating during prolonged operations. Wiring should comply with local electrical codes, and safety precautions like proper grounding are essential. Routine maintenance typically involves firmware updates every six months and periodic calibration checks to maintain accuracy.

Quality & Certifications

This product carries certifications such as CE, UL, and RoHS compliance, ensuring adherence to global safety and environmental standards. The manufacturer offers a 12-month warranty, covering defects in materials and workmanship under normal usage conditions.

Order Placement Process: Delivery times range from one week for in-stock items to no more than a month for custom orders. A 50% advance payment secures your order, with the balance due upon delivery. We ship via FedEx, UPS, or DHL for fast, reliable service.

Reviews

There are no reviews yet.