Description

Woodward 9907-175: Reliable Speed Control for Industrial Turbines

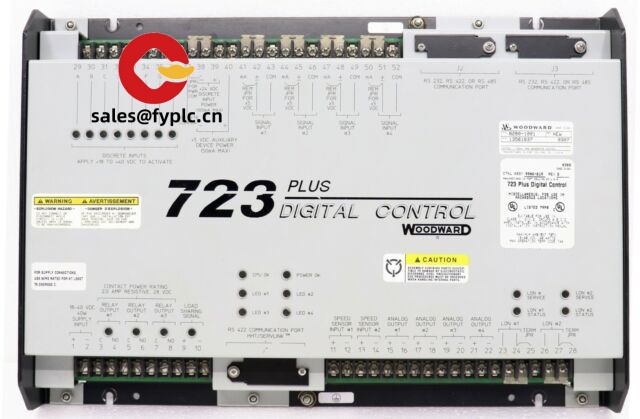

The Woodward 9907-175 is a precision-engineered speed control module designed to ensure optimal performance in industrial gas and steam turbines. From my experience, this model stands out for its ability to handle complex speed regulation tasks with minimal setup time, making it a go-to solution for power generation and oil & gas applications.

Key Features

- High Precision Speed Control: Ensures stable turbine operation even under fluctuating load conditions.

- Plug-and-Play Design: Reduces installation complexity, typically cutting commissioning time by up to 30% compared to older models.

- Dual Communication Ports: Supports Modbus and Ethernet/IP for seamless integration into existing systems.

- Robust Diagnostics: Built-in fault detection helps operators identify issues before they escalate, minimizing downtime.

Technical Specifications

| Specification | Details |

|---|---|

| Brand/Model | Woodward / 9907-175 |

| HS Code | 85371099 |

| Power Requirements | 110-240V AC, 50/60Hz |

| Dimensions & Weight | 300mm x 200mm x 100mm, 3.5kg |

| Operating Temperature | -20°C to +60°C |

| Signal Input/Output Types | Analog (4-20mA), Digital (Discrete I/O) |

| Communication Interfaces | Modbus RTU, Ethernet/IP |

| Installation Method | DIN Rail or Panel Mount |

Application Fields

This module finds extensive use in industries where precise turbine speed control is critical. For example, in power plants, the Woodward 9907-175 ensures consistent generator output during peak demand periods. Similarly, refineries rely on its accuracy to maintain safe operating speeds for compressors and pumps. You might notice that its rugged design also makes it suitable for harsh offshore environments.

Advantages & Value

One thing I appreciate about the Woodward 9907-175 is how it balances reliability with cost-effectiveness. Its backward compatibility with legacy Woodward systems means you won’t need to overhaul your entire setup—a huge plus when budgets are tight. Additionally, the availability of local technical support in many regions adds peace of mind for procurement teams concerned about long-term maintenance.

Installation & Maintenance

For proper installation, ensure the cabinet meets NEMA 4 standards and has adequate ventilation to prevent overheating. Wiring should comply with NEC guidelines, particularly for high-voltage connections. Routine maintenance includes firmware updates every six months and cleaning dust filters quarterly. Calibration checks annually seem to be sufficient for most users, though heavy-duty applications may require more frequent attention.

Quality & Certifications

The Woodward 9907-175 holds key certifications such as CE, UL, and RoHS compliance, ensuring safety and environmental responsibility. The manufacturer offers a standard one-year warranty, which can often be extended through service contracts. It appears that their commitment to quality assurance gives customers confidence in the product’s longevity.

Reviews

There are no reviews yet.