Description

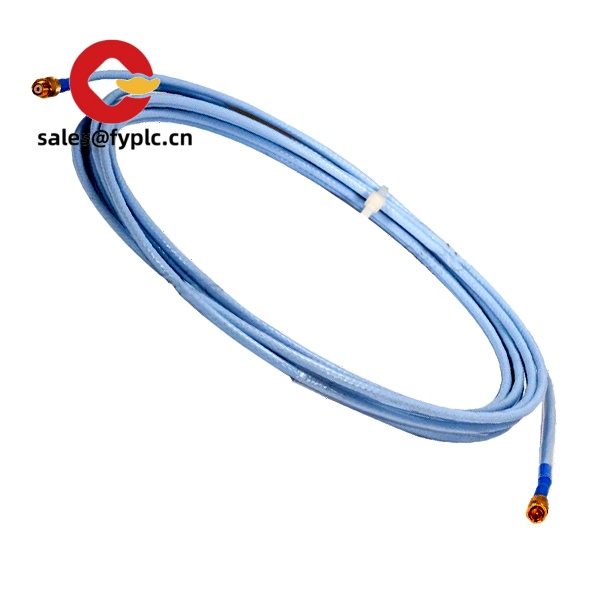

Bently Nevada 330130-045-00-CN – 3300 XL Extension Cable for Proximity Probe Systems

The BENTLY NEVADA 330130-045-00-CN is part of the 3300 XL proximity transducer system. It’s an extension cable that links a 3300 XL proximity probe to its Proximitor sensor, carrying the raw eddy-current signal with minimal noise pickup. From my experience, this cable is the “fit-and-forget” piece that keeps your vibration and shaft position measurements stable over long runs, especially in hot, electrically noisy machine halls. The “-045” variant typically indicates a 4.5 m length, and the “CN” suffix seems to denote a regional packaging/label variant while keeping the same electrical performance.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in-stock items; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express delivery methods: FedEx, UPS, DHL

Key Features

- Purpose-built for 3300 XL systems – Designed to connect 3300 XL proximity probes to their Proximitor sensors, preserving signal integrity over distance.

- Low-noise coaxial design – Double-shielding and factory terminations reduce electromagnetic interference in motor rooms and turbine decks.

- ClickLoc-style connections – Secure, repeatable connectors help prevent looseness from vibration; you might notice fewer intermittent faults after upgrade.

- Length variant “-045” – Typically the 4.5 m option, useful when probes are mounted deep in bearing housings but Proximitor racks are cabinet-mounted.

- Rugged jacket – Suited for industrial routing with ties, trays, or conduits; abrasion-resistant in most cases.

- Compatibility – Works with 3300 XL 5 mm and 8 mm probe families and matching Proximitor sensors.

- Stable metrology – Maintains the calibrated transducer chain response when paired with matching probes and proximitor modules.

Technical Specifications

| Item | Details |

|---|---|

| Brand / Model | Bently Nevada 330130-045-00-CN (3300 XL Extension Cable) |

| HS Code | 8544.20 (Coaxial cable) |

| Power Requirements | Not applicable (passive coaxial cable) |

| Length | 4.5 m (typical for “-045” variant) |

| Operating Temperature | Typically −51 to +121 °C for 3300 XL cabling (application dependent) |

| Signal Type | Eddy-current probe signal via shielded coax (probe-to-Proximitor) |

| Communication Interfaces | None (analog passive link) |

| Installation Method | Cabinet or field routing; connects between 3300 XL probe and Proximitor sensor; secure with clamps/ties; observe bend radius |

Application Fields

Commonly used in rotating machinery monitoring: steam and gas turbines, compressors, large motors, generators, gearboxes, and critical pumps. In many cases, plants in power generation, oil & gas, petrochemical, paper, and steel rely on this cable to keep the 3300 XL transducer chain stable when the Proximitor must sit in a protected cabinet some meters away from the bearing housing.

Advantages & Value

- Reliability under vibration – Secure terminations typically reduce intermittent signal drops that waste troubleshooting hours.

- Compatibility continuity – Matches the 3300 XL ecosystem, helping you preserve existing calibration curves and proximitor settings.

- Lower lifetime cost – Fewer re-terminations, fewer nuisance faults, and faster swap-out save technician time.

- Supportable at scale – Clear part coding makes spares planning easier across multi-unit sites.

Installation & Maintenance

- Route in trays or conduits away from high-voltage lines and VFD outputs; keep a sensible separation to reduce EMI coupling.

- Respect minimum bend radius; avoid crushing or repeated sharp bends near connectors.

- Use labeled ends to connect probe → extension → Proximitor; hand-tighten connectors to manufacturer’s guidance.

- Cabinet environment: ventilated, clean, and within the Proximitor’s ambient temperature limits; mount securely.

- Maintenance: visual inspection during outages, check connector tightness, confirm gap voltage stability on the monitor; replace if jacket damage or intermittent behavior is observed.

Quality & Certifications

- Typical compliance for Bently Nevada cabling includes CE and RoHS; manufacturing under ISO 9001 systems.

- Manufacturer’s warranty is typically 1 year; our supplied units are covered by a 365-day warranty as part of the order terms above.

Supporting Components (for a complete 3300 XL chain)

- 3300 XL Proximity Probes (5 mm and 8 mm series) – front-end sensors mounted at the machine, paired by length with the extension cable.

- 3300 XL Proximitor Sensors – signal conditioning modules installed in the cabinet, providing gap voltage and vibration/position output.

- Monitoring System Channels (e.g., 3500 series monitors) – consume the Proximitor outputs for protection and diagnostics.

Reviews

There are no reviews yet.