Description

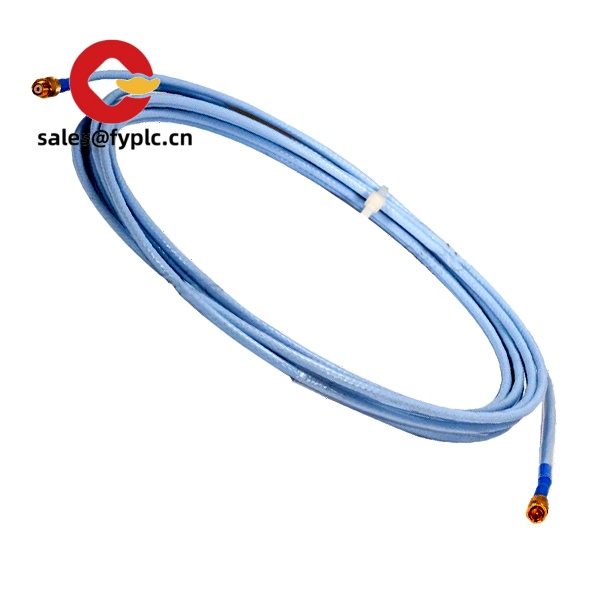

BENTLY NEVADA 330130-40-01-05 – Extension Cable for 3300 XL Proximity Transducer Systems

The BENTLY NEVADA 330130-40-01-05 is a factory‑molded extension cable designed for 3300 XL proximity probe systems, used widely on turbines, compressors, and critical pumps. From my experience, this part is the go‑to when you need a reliable 40‑foot run between the probe and the Proximitor sensor without signal drift or nuisance noise. The “-01-05” optioning typically indicates a specific connector configuration with stainless‑steel armor, which makes routing in harsh plant environments much easier and safer.

Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; not more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

Key Features

- Purpose-built for 3300 XL systems – Maintains system accuracy for vibration and shaft position measurements over a 40 ft run.

- Factory-molded connectors – Consistent impedance and excellent noise immunity; you avoid drift caused by field-terminated joints.

- Armor option (-05) – Stainless-steel armor helps protect the cable from abrasion and pinch points; ideal for cable trays or near rotating equipment.

- High-temperature jacket – Typically PFA-jacketed construction rated for elevated temperatures common around bearings and hot casings.

- Stable signal transfer – Low-noise coaxial design preserves proximitor linearity and scale factor in most installations.

- Drop-in compatibility – Mates with standard Bently Nevada probe leads and Proximitor sensors without adapters.

Technical Specifications

| Brand / Model | BENTLY NEVADA 330130-40-01-05 (Extension Cable) |

| HS Code | 8544.20 (Coaxial cable and other coaxial electric conductors) |

| Power Requirements | N/A (passive cable) |

| Length | 40 ft (approx. 12.2 m) |

| Dimensions & Weight | Cable OD typically ~5 mm unarmored; ~8 mm with stainless-steel armor (option -05). Weight varies with routing hardware. |

| Operating Temperature | Typically -51 to +177 °C (-60 to +350 °F), jacket dependent |

| Signal Input/Output | Coaxial extension for proximity probe signal between probe lead and Proximitor sensor |

| Communication Interfaces | None (analog proximity transducer system) |

| Installation Method | Direct mate to Bently Nevada 3300 XL probe and Proximitor; route in tray/conduit; armored for exposed runs |

| Compatibility | 3300 XL 5 mm & 8 mm proximity transducer systems (typical) |

Application Fields

You’ll typically see the 330130 series on high-value rotating assets where continuous condition monitoring matters:

- Steam and gas turbines (radial/axial position, vibration)

- Compressors and expanders in petrochemical plants

- Large process pumps and motors in refineries and power generation

- Gearboxes and test stands where long, protected cable runs are needed

Advantages & Value

- Reliability – Molded terminations reduce intermittent faults that usually come from field-made joints.

- Compatibility – Works with existing 3300 XL probes and Proximitor modules, so you don’t touch your calibration chain.

- Lower lifecycle cost – Armor option (-05) tends to survive routine maintenance handling, which saves repeat replacements.

- Stocking simplicity – 40 ft is a common length for 14 m systems when paired with standard probe leads.

One thing I appreciate is how forgiving the armored version is when technicians pull it through crowded trays. A maintenance engineer told me they swapped in this -40-01-05 variant during an outage and didn’t have to re-route conduit—the bend and protection were good enough to go back in service the same shift.

Installation & Maintenance

- Environment – Route away from high-heat sources where possible; provide ventilation in enclosed cabinets.

- Routing – Use trays or conduit; armored jacket helps for exposed runs. Maintain a gentle bend radius (typically ≥10× OD unarmored; ≥12× OD armored).

- Connections – Seat connectors fully on the probe lead and Proximitor; avoid over-tightening knurled couplers.

- Grounding – Keep the transducer cabling separate from high-voltage motor leads to minimize induced noise.

- Preventive care – Periodic visual inspection for jacket damage; clean connectors with lint-free swabs; verify system readings after outages.

- Firmware/Calibration – No firmware on the cable, but after replacement it’s good practice to check gap voltage and scale on the Proximitor.

Quality & Certifications

- Manufactured under ISO 9001 quality systems (manufacturer-level)

- Typically CE marked and RoHS compliant for industrial use

- 365-day warranty coverage

You might notice there are multiple option codes for 330130 cables. If your plant standard calls for a different connector or jacket type, share the full code on your existing tag—we’ll match it so the replacement fits first time.

Reviews

There are no reviews yet.