Description

Honeywell 51154724-100 – Legacy TPS/TDC I/O Module for Reliable System Upkeep

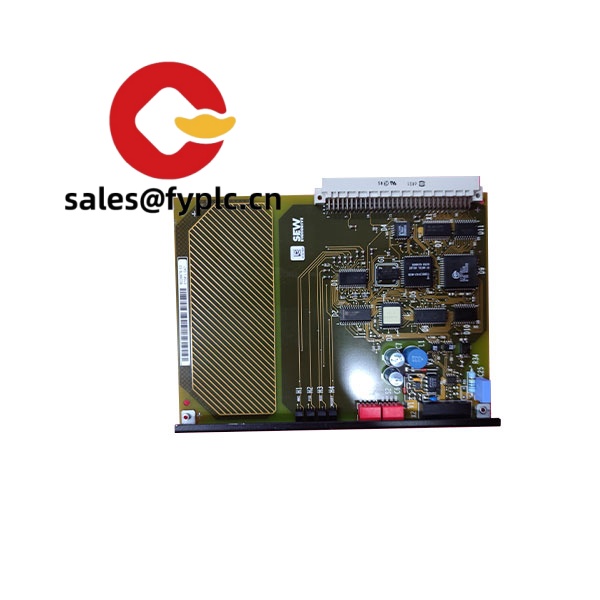

The Honeywell 51154724-100 is a legacy I/O module used in Honeywell TPS/TDC control systems, typically specified as a board-level replacement within existing I/O racks. From my experience, plants use this part to keep mature units running smoothly without forcing a full platform migration. It’s a straight, rack-based module intended to integrate with the original Honeywell backplane and termination assemblies, so wiring changes are minimal and loop checks stay predictable.

You might notice that the real value here is continuity—drop it in, verify assignment, and you’re back to steady operations. One thing I appreciate is how consistently it behaves across cabinets when the environment is controlled and clean. In many cases, teams pair it with the original IOTA/FTA hardware and keep the channel mapping exactly the same to limit downtime.

Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

Key Features

- Designed for Honeywell TPS/TDC racks – Backplane-mounted module for legacy cabinets; reduces retrofit complexity.

- Backplane-powered – Draws power from the Honeywell I/O chassis, so no external supply rewiring is typically required.

- Field wiring continuity – Works with paired IOTA/FTA hardware, helping maintain existing loop terminations and labeling.

- Diagnostic-friendly – Supports the usual rack indicators and system health checks; technicians can validate status quickly.

- Service-proven in harsh process areas – Performs reliably in clean, conditioned cabinets common to refineries, chemicals, and power units.

- Straight replacement approach – In most cases, it drops into the same slot assignment, minimizing re-engineering time.

Technical Specifications

| Brand / Model | Honeywell 51154724-100 |

| HS Code | 8537.10 (Boards/panels for electric control, ≤1000 V) |

| Power Requirements | Backplane powered from Honeywell I/O chassis; low power draw (typically < 10 W) |

| Dimensions & Weight | Standard Honeywell rack card format; approx. 240 × 25 × 240 mm; ~0.5 kg typical |

| Operating Temperature | 0 to 50°C (control cabinet), non‑condensing ambient |

| Signal I/O Types | Used within Honeywell TPS/TDC racks alongside IOTA/FTA; assignment may support discrete or analog channels depending on system configuration (verify before ordering) |

| Communication Interfaces | Honeywell backplane interface to the I/O subsystem; no external user ports |

| Installation Method | Pluggable card for Honeywell rack slot; secure in guides; ESD-safe handling recommended |

Application Fields

The 51154724-100 is commonly deployed in mature Honeywell installations across oil & gas refining, petrochemicals, specialty chemicals, power generation, and pulp & paper. Typical jobs include replacing a suspect I/O board during turnaround, adding a spare slot for loop expansion, or swapping a degraded module during a planned outage. A maintenance lead at a midstream facility told me they keep two units on the shelf—one for immediate swap, one as insurance for the next shutdown.

Advantages & Value

- Reliability – Stable behavior in conditioned cabinets; reduces nuisance trips and intermittent faults.

- Compatibility – Works within Honeywell TPS/TDC racks and with existing IOTA/FTA wiring, which typically avoids re-termination.

- Downtime savings – Drop-in replacement helps teams recover quickly during unplanned events.

- Lifecycle strategy – Extends the service life of installed assets while you plan a longer-term migration to Experion, if that’s on the roadmap.

- Technical support – We assist with cross-checking revisions and slot assignments to cut trial-and-error on site.

Installation & Maintenance

- Cabinet standards – Install in a clean, ventilated control cabinet; maintain ambient within 0–50°C and non‑condensing humidity.

- Wiring – Keep field wiring on the paired IOTA/FTA; verify shield terminations and channel mapping before powering up.

- Safety – Follow lockout/tagout and ESD precautions; hot-swap is not recommended unless documented by your site procedures.

- Commissioning – After installation, perform loop checks, confirm module status in the engineering tools, and document any channel scaling.

- Routine care – Quarterly visual inspection for dust; yearly connector reseat and cabinet cleaning. Firmware/configuration alignment should match your system image and revision policy.

Supporting Components We Can Supply

If you’re refreshing a whole bay, we can also help with Honeywell I/O chassis hardware, IOTA (Input/Output Termination Assembly), FTA (Field Terminal Assembly), and compatible power supplies and interconnects. In most cases, keeping the same IOTA/FTA pairing with this module preserves all field terminations and reduces commissioning time.

Quality & Certifications

- CE marking and UL recognition are typically available for Honeywell rack modules used in process control environments.

- Manufactured under ISO 9001 quality systems (manufacturer-level standard).

- RoHS status may vary by revision and manufacturing year; we can confirm per lot before shipment.

- Warranty: 365 days from delivery.

Practical note: Because 51154724-100 is part of a legacy platform, it’s wise to share your current rack type, slot location, and any known revision constraints. We’ll cross-check compatibility so the module arrives ready for a clean swap.

Reviews

There are no reviews yet.