Description

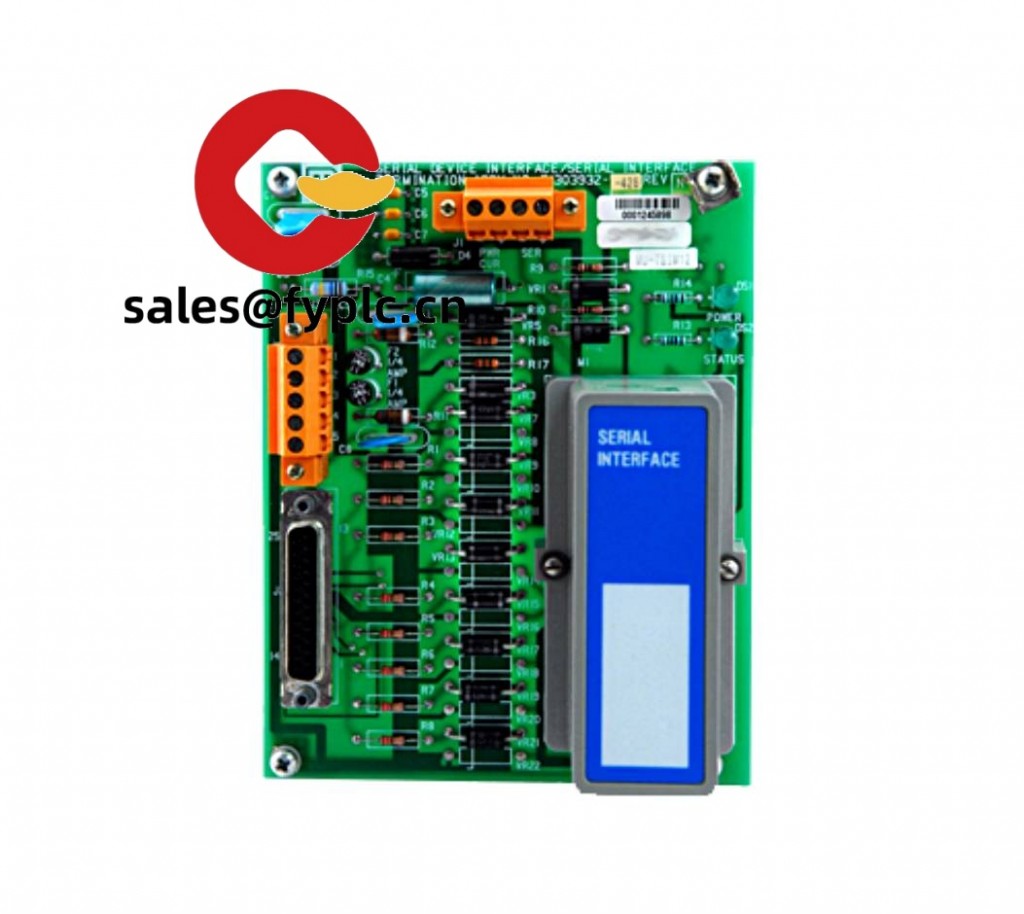

Honeywell 51202329-606 – TPS/TDC 3000 Control System Module (PWA) for Reliable Plant Upkeep

The Honeywell 51202329-606 is a Printed Wiring Assembly commonly used in Honeywell TPS/TDC 3000 nodes. From my experience supporting brownfield plants, this part is typically selected as a drop-in replacement to keep legacy controller and I/O nodes running without re-engineering. You might notice the “-606” revision marking—procurement teams often use it to match installed hardware levels and maintain system redundancy rules.

Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in-stock; no more than one month at the latest

- Payment terms: 50% advance payment, full payment for delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- Genuine Honeywell spare – 51202329-606 PWA used in TPS/TDC 3000 control system nodes for lifecycle continuity.

- Drop-in compatibility – Designed to fit the standard Honeywell card file/backplane, no field wiring changes in most cases.

- Revision-managed (-606) – Helps match installed base revisions, which typically reduces commissioning time and risk.

- Industrial build – Robust PCB design; many units in this family feature conformal coating for cabinet environments.

- Backplane powered – No external power leads; simplifies installation and keeps cabinets tidy.

- Tested spare – Units are functionally checked prior to shipment to minimize site downtime on arrival.

Technical Specifications

| Brand / Model | Honeywell 51202329-606 |

| Product Type | Control system module (PWA) for Honeywell TPS/TDC 3000 |

| HS Code | 8538.90 – Parts suitable for use with industrial control apparatus |

| Power Requirements | Powered via the system backplane; no external power input |

| Operating Temperature | Typically 0 to 55°C cabinet ambient (series typical; observe site standards) |

| Signal I/O Types | Internal system bus processing; not a direct field I/O terminator in most configurations |

| Communication Interfaces | Backplane interface to the node; LCN/UCN communications handled at node level |

| Installation Method | Plug-in module for Honeywell card file/chassis; front-panel fastening |

Application Fields

This module is commonly found in legacy and migration-stage process control environments where Honeywell TPS/TDC 3000 nodes remain in service:

- Oil & Gas (upstream, refining, midstream compressor stations)

- Chemical and petrochemical units

- Power generation and utilities balance-of-plant

- Pulp & paper and continuous process lines

- Metals, mining, and material handling with long-life DCS assets

Advantages & Value

- Reliability – A like-for-like Honeywell replacement typically restores node stability fast.

- Compatibility – Revision-aligned hardware helps avoid nuisance faults and minimizes tuning changes.

- Cost Savings – Extends the life of installed TPS/TDC 3000 assets without a full system upgrade.

- Technical Support – Assistance with revision matching, part identification, and pre-shipment testing details.

One thing I appreciate is how quickly maintenance teams can swap these boards. A customer maintenance lead told us they completed a like-for-like replacement in under 30 minutes during a planned pause, and the node rejoined the network without additional field wiring work.

Installation & Maintenance

- Cabinet environment – Keep ambient within typical Honeywell cabinet specs (often 0–55°C), provide clean, dry air and adequate ventilation.

- Handling – Observe ESD precautions; use grounded wrist straps and antistatic bags.

- Wiring – This board is backplane-connected; verify backplane connectors are clean and undamaged before insertion.

- Seating & fastening – Slide along card guides until fully seated; secure front-panel screws to avoid vibration-related intermittence.

- Commissioning – After power-up, check node health/status LEDs and confirm the controller recognizes the board; match firmware where applicable.

- Routine care – Periodic cabinet dust removal, connector inspection, and keeping a known-good spare on the shelf typically reduce downtime.

Quality & Certifications

- Certifications – Honeywell control hardware is commonly supplied with CE and UL compliance for industrial environments.

- RoHS – Legacy TPS/TDC 3000 modules may predate RoHS; availability of RoHS versions depends on revision and build date.

- Quality assurance – Units are inspected and function-tested prior to shipment; Certificate of Conformance can be provided on request.

- Warranty – 365-day warranty coverage; OEM terms may vary for legacy spares, so our coverage ensures practical protection in the field.

Note: System compatibility can be revision-dependent. If you share the installed node type and current board revision, we can verify a one-to-one match for 51202329-606 before shipment.

Reviews

There are no reviews yet.