Description

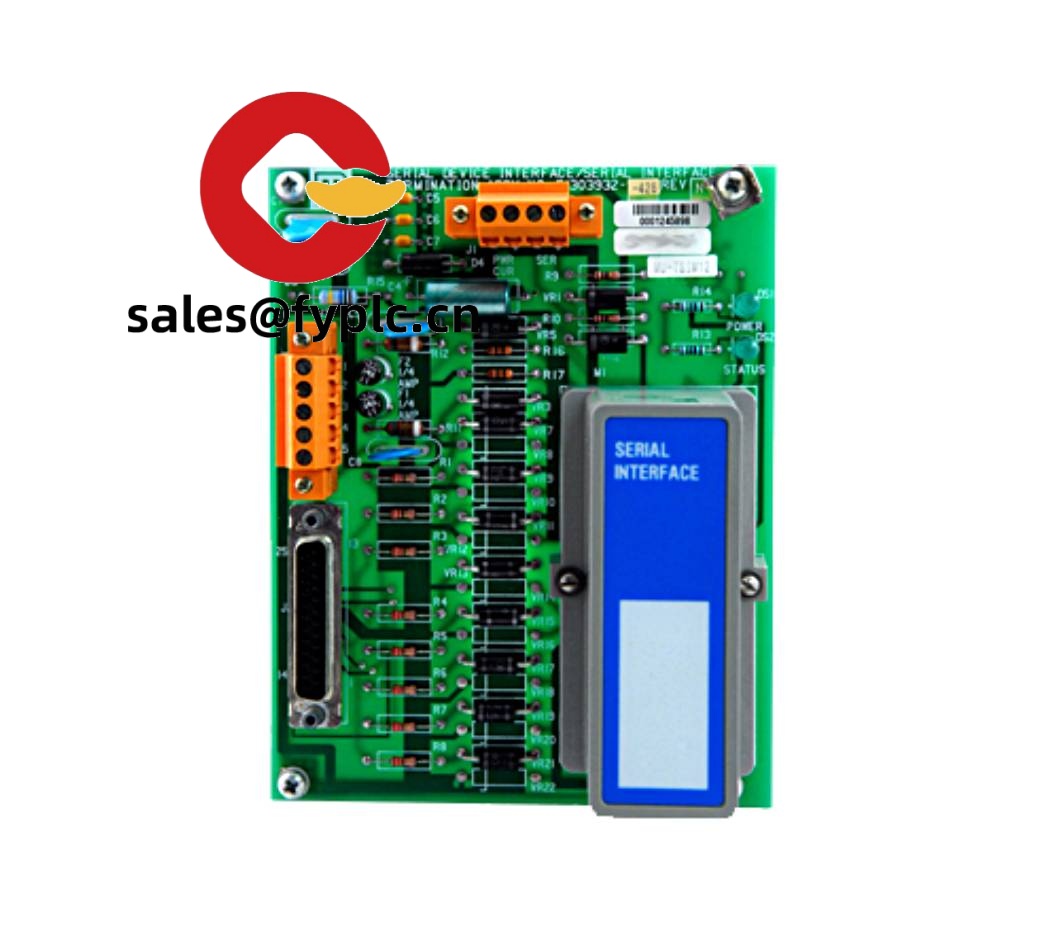

Honeywell 51303932-476 – Plug‑in I/O Module Board for TPS/TDC Systems

The Honeywell 51303932-476 is a plug-in I/O module board used in Honeywell TPS/TDC control systems, typically as a field I/O interface within a standard Honeywell I/O chassis. It’s designed for straightforward swap-and-replace maintenance, helping teams restore loops and marshaled signals without reworking field wiring. From my experience, plants keep this part on the shelf as a drop-in spare to minimize downtime during planned shutdowns or when a channel bank drifts out of spec.

Order Placement Process & Guarantees

- Warranty: 365 days

- Lead time: In-stock items typically ship within 1 week; no more than 1 month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

Key Features

- Drop‑in compatibility – Works within Honeywell TPS/TDC I/O chassis, so cabinet layout and terminations typically remain unchanged.

- Backplane-powered – No external power feed; the module draws power from the system backplane for tidy wiring and easy service.

- Field I/O via TA – Interfaces to field signals through Honeywell termination assemblies (TA), keeping loop checks and isolation consistent with site standards.

- Service-friendly design – Plug‑in card form factor with secure latching; simplifies hot-swap in planned outages.

- Lifecycle alignment – Suitable for maintenance and MRO programs in legacy TPS/TDC fleets, helping extend asset life and reduce change risk.

Technical Specifications

| Brand / Model | Honeywell 51303932-476 |

| Product Type | Plug-in I/O module board (TPS/TDC system spare) |

| HS Code | 853890 (Parts for switching/controlling apparatus) |

| System Compatibility | Honeywell TPS/TDC I/O chassis with backplane interface |

| Power Requirements | Backplane-powered (typ. 5 V/24 V supplied by chassis) |

| Operating Temperature | 0–55°C (typical industrial range) |

| Signal I/O | Field I/O via dedicated Honeywell termination assemblies; control via backplane bus |

| Communication Interface | Honeywell proprietary I/O backplane (within chassis) |

| Installation Method | Plug-in card for Honeywell rack/chassis; locking latch design |

| Dimensions & Weight | Standard Honeywell plug‑in board form factor; lightweight module (typically < 1 kg) |

Application Fields

- Refining and petrochemical units (process heaters, fractionation, utilities)

- Power generation and cogeneration balance-of-plant controls

- Pulp & paper, metals, and chemicals (batch and continuous lines)

- Water/Wastewater process control where legacy TPS/TDC cabinets are in service

Advantages & Value for Procurement

- Risk reduction: Direct replacement helps avoid re-engineering, patchwork adapters, or re-termination work.

- Cost control: Extends lifecycle of existing cabinets and controllers; in many cases far cheaper than migration.

- Compatibility: Aligns with Honeywell backplane and TA strategy—no surprises for maintenance teams.

- Supportability: Units can be function-tested on the bench; firmware/config alignment is straightforward in most cases.

- Availability: Stock-backed delivery reduces outage exposure and helps meet turnaround schedules.

Installation & Maintenance

- Environment: Mount in a clean, dry cabinet with adequate ventilation; follow Honeywell chassis guidelines.

- Power-down procedure: In most cases, isolate power to the I/O chassis before removal/installation; observe site LOTO procedures.

- ESD protection: Use wrist straps and antistatic handling. Avoid touching connector pins and components.

- Seating & latching: Align rails carefully, insert fully until connectors are firmly engaged, and secure latches.

- Wiring checks: Verify TA terminations and channel assignment; run loop checks where practical.

- Revision compatibility: Confirm hardware/firmware revisions with the controller node to avoid nuisance faults.

- Routine care: Periodic visual inspection, dust removal with dry air, and recordkeeping of swap dates and loop performance.

Supporting components typically used with this board include Honeywell I/O chassis, termination assemblies (8/16‑channel variants), and shielded field wiring cables. One thing I appreciate is how the TA approach keeps cabinet wiring neat, which usually speeds up troubleshooting.

Quality & Certifications

- Quality system: Honeywell manufacturing is typically ISO 9001-based.

- Safety/EMC: Many TPS/TDC modules are CE-marked and UL/CSA recognized; specifics may vary by revision.

- RoHS: Legacy industrial spares may be RoHS-exempt; we can verify per serial/revision if needed.

- Warranty: 365-day coverage as stated above.

What to Expect Next

Share your required quantity, target ship date, and any preferred hardware/firmware revision notes. We’ll confirm stock, provide a formal quote with HS code 853890, and align shipment via FedEx/UPS/DHL based on your routing guide. If you’d like, we can add a bench test report to the delivery file—many teams find that useful for commissioning records.

Reviews

There are no reviews yet.