Description

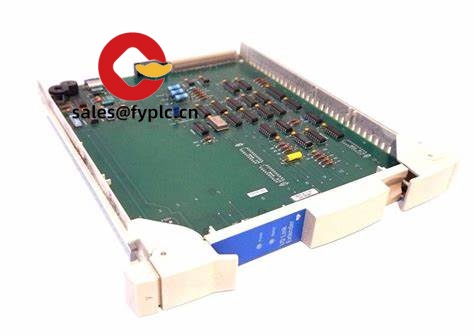

Honeywell 51304362-300 – I/O Termination Assembly for TPS/TDC Field Wiring

The Honeywell 51304362-300 is a field-wiring termination board typically used in TPS/TDC 3000 architectures. In many cases it serves as the I/O Termination Assembly (IOTA) that bridges plant instruments to the associated I/O electronics. From my experience, teams choose it as a like-for-like replacement to keep existing marshalling and wiring intact, minimize downtime, and maintain full compatibility with installed Honeywell I/O processors.

One thing I appreciate is how these IOTA-style boards keep signal wiring tidy and serviceable—clear terminal labeling, robust screw clamps, and proven insulation spacing. You might notice that it behaves as a passive interface (no external power), which tends to simplify commissioning and long-term maintenance.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in-stock items; no more than one month at the latest

- Payment method: 50% advance payment; full payment prior to delivery

- Express delivery methods: FedEx, UPS, DHL

Key Features

- TPS/TDC ecosystem fit – Designed to work within Honeywell DCS cabinets, pairing with the appropriate I/O electronics.

- Passive termination – No external power draw; reduces failure points and simplifies troubleshooting.

- Field-proven wiring interface – Screw-clamp terminals and clear channel markings for fast, mistake-resistant hookups.

- Service-friendly layout – Facilitates loop checks, channel isolation, and replacement during planned outages.

- Consistent footprint – Typically matches standard Honeywell I/O carriers, keeping cabinet layouts unchanged.

- ESD-safe construction – Industrial-grade PCB and components suitable for control-room environments.

Technical Specifications

| Brand / Model | Honeywell 51304362-300 |

| HS Code | 8538.90 (Parts suitable for apparatus of heading 8537) |

| Power Requirements | Passive termination board; no external power input |

| Dimensions & Weight | Standard Honeywell IOTA footprint; typically mid-density board in the 0.4–0.6 kg range (contact us for drawing) |

| Operating Temperature | 0 to 55°C typical control-cabinet environment; 5–95% RH non-condensing (typical) |

| Signal Input/Output Types | Field signal termination (AI/AO/DI/DO depending on paired I/O module); screw-clamp terminals |

| Communication Interfaces | Internal edge/backplane connection to Honeywell I/O electronics; no external network ports |

| Installation Method | Cabinet/carrier mounting in Honeywell DCS racks; wire via labeled terminal blocks |

Application Fields

This model is commonly used in TPS/TDC-based control systems across oil & gas, petrochemical, chemical, power generation, pulp & paper, metals, and water/wastewater. Typical jobs include replacing worn termination boards during turnarounds, adding channels during small I/O expansions, and restoring loop integrity after cabinet refurbishments. A maintenance lead at a refinery mentioned it “dropped straight into the existing carrier, no rewiring headaches,” which seems to be the norm with these boards.

Advantages & Value

- Like-for-like compatibility – Keeps existing cabinet layouts and loop documentation intact, reducing engineering time.

- Short downtime – Passive design and familiar terminal layout speed up swap-outs during shutdowns.

- Risk reduction – Genuine Honeywell form/fit lowers the chance of wiring errors and nuisance trips.

- Lifecycle support – Suitable for sustaining TPS/TDC assets while larger migration plans are scheduled.

- Technical backup – We can share wiring notes and typical torque values to help your team verify connections quickly.

Installation & Maintenance

- Environment – Install in a clean, ventilated control cabinet within the specified temperature and humidity range. Avoid dust and corrosive atmospheres.

- Mounting – Fit to the designated Honeywell carrier/rack positions; ensure all fixing screws are secure and the edge connector is fully seated.

- Wiring – Use the labeled terminal channels; segregate analog, digital, and power cabling; maintain shield terminations as per site standards.

- ESD and safety – De-energize affected loops, use ESD protection, and verify isolation before handling conductors.

- Routine checks – Periodically inspect for loose terminals, discoloration, or damaged insulation; re-torque terminals during outages and clean with an ESD-safe brush or dry air.

- Firmware note – The termination board itself is passive; if paired I/O electronics are replaced, confirm firmware compatibility at the I/O processor level.

Quality & Certifications

- Manufacturing typically aligned with ISO 9001 processes

- CE conformity and RoHS status available for most TPS/TDC assemblies (varies by revision)

- UL/CSA recognition may apply to specific module families and regions

- Vendor warranty: 365 days from delivery

Related/Supporting Components

The 51304362-300 is typically used alongside Honeywell I/O processors and carriers in TPS/TDC systems, such as Analog Input (AI), Analog Output (AO), Digital Input (DI), or Digital Output (DO) I/O modules. Common accessories include carrier backplanes, shield bars, and field cable assemblies. If you share your current rack layout or a cabinet photo, we can suggest the exact mates and any jumper or shield kit that tends to be required.

Reviews

There are no reviews yet.