Description

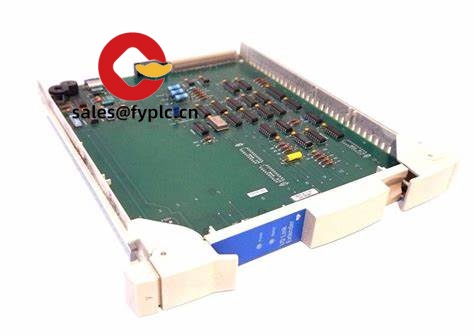

Honeywell 51304419-150 – Pre‑terminated I/O Link Cable for TPS/Experion I/O Cabinets

The Honeywell 51304419-150 is a factory-terminated I/O link cable used to connect I/O modules to their termination assemblies in Honeywell TPS and Experion Series C cabinets. In many cases, the “-150” variant corresponds to a 15 ft (approx. 4.6 m) length, which tends to be the sweet spot for standard cabinet-to-termination routing without excess slack. From my experience, this assembly is chosen to reduce wiring errors, speed up cabinet builds, and keep signal integrity consistent with Honeywell’s original layouts.

Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express Options: FedEx, UPS, DHL

Key Features

- OEM-terminated ends – Plug-and-lock connectors help avoid field crimping and pinout mistakes.

- Length variant (-150) – Typically around 15 ft, suitable for standard cabinet routing with tidy slack management.

- Signal integrity – Multi-pair construction supports both analog and discrete channels; shielding reduces cabinet noise pickup in typical installations.

- Cabinet-friendly jacket – Designed for indoor panel use with manageable bend radius for tighter turns.

- Backwards compatibility – Commonly used across Honeywell TPS / Experion Series C I/O terminations to maintain consistent wiring practices.

- Faster builds and change-outs – Pre-labeled ends in many cases; makes FAT/SAT and maintenance swaps more predictable.

Technical Specifications

| Brand / Model | Honeywell 51304419-150 |

| HS Code | 8544.42 (Insulated electric conductors fitted with connectors) |

| Power Requirements | None (passive cable assembly) |

| Dimensions & Weight | Length variant approx. 15 ft (≈4.6 m). Weight typical for multi-pair cabinet harness. |

| Operating Temperature | Typically 0 to +60°C cabinet environments |

| Signal I/O Types | Multi-pair I/O link harness for analog and discrete channels between I/O modules and termination assemblies |

| Communication Interfaces | Not applicable (backplane-style I/O link cable) |

| Connectors | Factory-terminated, keyed/locking connectors compatible with Honeywell I/O terminations |

| Installation Method | Panel/cabinet routing; plug-in at both ends; use strain relief and maintain bend radius |

Application Fields

Typically used in refining, petrochemical, power generation, pulp & paper, pharma, and specialty chemicals—anywhere Honeywell TPS or Experion Series C I/O cabinets are deployed. You might notice that these assemblies are especially helpful during:

- New cabinet builds where consistent pinout and dress-out are required

- Brownfield expansions adding additional I/O banks

- Migrations or cabinet refurbishments where downtime needs to be minimized

- Field replacements when damaged harnesses cause intermittent channel faults

Advantages & Value

- Reliability – OEM pinout and termination lowers the risk of miswiring and channel crosstalk.

- Compatibility – Designed for Honeywell I/O layouts, so cabinet integration is straightforward in most cases.

- Cost Savings – Cuts field labor and rework; faster FAT/SAT and quicker commissioning.

- Spares Strategy – Keeping a like-for-like length variant on the shelf simplifies maintenance planning.

- Technical Support – Guidance on routing, bend radius, and shield continuity if you’re standardizing across multiple cabinets.

Installation & Maintenance

- Environment – Install in clean, dry control cabinets. Maintain ventilation and avoid routing near high-voltage or VFD power cables where possible.

- Routing – Respect minimum bend radius (a conservative practice is ≥10× outer diameter). Add strain relief and label both ends.

- Shielding & Ground – Keep shield continuity per Honeywell cabinet standards; terminate shields at the designated end to control noise.

- Wiring Checks – Verify keyed orientation before mating; perform continuity checks if a harness has experienced mechanical stress.

- Routine Care – Periodically inspect for jacket nicks, crushed sections, or loose latch hardware. Clean dust with dry lint-free cloth; avoid solvents.

- Firmware – Not applicable for this passive cable, but it’s wise to pair replacements with I/O module firmware baselines defined by your site standard.

Quality & Certifications

- Manufacturing Quality: Produced under Honeywell’s quality system (ISO 9001 framework).

- Regulatory: As a passive cable assembly, individual CE/UL marking is typically not applied; used within certified cabinet systems.

- RoHS: RoHS-compliant supply can be provided on request, depending on available stock.

- Warranty: 365 days replacement/repair coverage per our sales terms.

Field Note

A maintenance lead at a power plant told us they swapped in the 51304419-150 during a weekend outage and shaved a few hours off their schedule—no re-terminations, no chasing intermittent faults—just plug, dress, and verify signals.

Reviews

There are no reviews yet.