Description

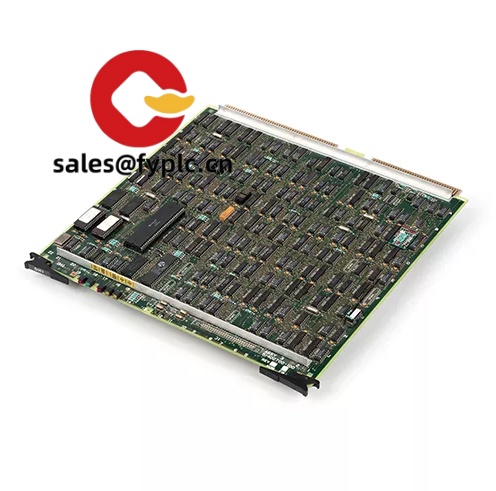

Honeywell 51400700-100 – I/O Termination Assembly for TDC/Experion Cabinets

The Honeywell 51400700-100 is commonly used as an I/O termination assembly within Honeywell TDC 2000/TDC 3000 and many Experion PKS cabinets. From my experience, it’s the piece that keeps field wiring neat, reliable, and serviceable—pairing with your I/O processor (IOP) on the backplane while presenting clean screw terminals (or similar) for plant wiring. You might notice that swaps are fast because the footprint and connectors typically match existing Honeywell layouts, so you don’t re-engineer marshalling.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week for in-stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Backplane-linked termination – Connects field I/O to the Honeywell I/O processor (IOP) through the standard backplane interface, helping keep signal integrity stable.

- Field-friendly wiring – Typically screw or clamp terminals for quick loop termination; technicians appreciate the clear channel mapping and labels.

- Form-fit compatibility – Sized for standard Honeywell marshalling/rack layouts, which usually means no cabinet rework during replacement.

- Mixed-signal support – Used across analog and discrete loops depending on the paired IOP/I/O pack; reduces spares complexity.

- Serviceable in minutes – Tooling is straightforward; in many cases, swap time is under 10 minutes with proper lockout/tagout.

- Industrial temperature rating – Suitable for control-room cabinets, typically 0–55°C environments with proper ventilation.

Technical Specifications

| Brand / Model | Honeywell 51400700-100 |

| HS Code | 8538.90 (Parts suitable for use with industrial control equipment of heading 8537) |

| Power Requirements | No separate power; interfaces via the IOP/backplane (passive termination in most setups) |

| Operating Temperature | 0 to 55°C typical for control-room cabinet installations |

| Signal Input/Output Types | Field-wiring termination for analog (e.g., 4–20 mA) and discrete signals; actual channel type depends on paired IOP/I/O pack |

| Communication Interfaces | Backplane edge connector to I/O processor; terminal blocks to field devices |

| Installation Method | Panel or DIN-rail mounting inside a ventilated control cabinet/marshalling panel |

Application Fields

This model is typically found in continuous process industries where Honeywell DCS systems dominate: oil & gas (upstream, refining), chemicals, power generation, pulp & paper, water/wastewater, and pharmaceuticals. If you’re standardizing cabinets or extending legacy TDC nodes within an Experion environment, this part keeps field loops organized and minimizes commissioning headaches.

Advantages & Value

- Lifecycle continuity – Works within established Honeywell I/O structures, reducing redesign work during expansions or maintenance.

- Lower installation risk – Field terminals and channel markings help technicians verify loops quickly; fewer wiring errors in many cases.

- Reduced downtime – Fast swap-in/out and no separate power simplify planned outages.

- Compatibility-first approach – Pairs with Honeywell IOPs across analog and digital cards used in TDC/Experion nodes.

- Test support – We functionally check parts prior to shipment; you receive a unit ready to integrate.

Installation & Maintenance

- Cabinet environment – Install in a clean, dry control-room cabinet with ventilation; keep ambient within 0–55°C and below 95% RH non-condensing.

- Mounting – Panel or DIN-rail per Honeywell cabinet standards; ensure proper backplane alignment and secure ground bonding.

- Wiring – Use ferruled conductors, maintain separation between analog, digital, and power wiring, and torque terminals to spec to avoid intermittent faults.

- Safety – De-energize field loops and follow ESD handling. One thing I appreciate is how the terminal layout makes lockout/tagout checks straightforward.

- Routine care – Periodically re-torque terminals, remove dust with dry air, and visually check for discoloration or loose conductors. No firmware on the termination board; firmware lives on the IOP.

Quality & Certifications

- Certifications: Typically CE and UL recognized within the Honeywell system; RoHS compliance depends on production revision; manufacturer’s QMS aligns with ISO 9001.

- Warranty: 12 months (365 days) from delivery.

Common Supporting Components

- Honeywell I/O Processors (IOP) – Analog input/output and digital input/output cards that mate through the backplane.

- Field cabling kits – Pre-terminated cables for orderly marshalling and faster commissioning.

- DIN-rail/panel hardware – Mounting brackets and grounding kits for clean cabinet integration.

- Labeling accessories – Channel markers and loop tags for maintenance readability.

Reviews

There are no reviews yet.