Description

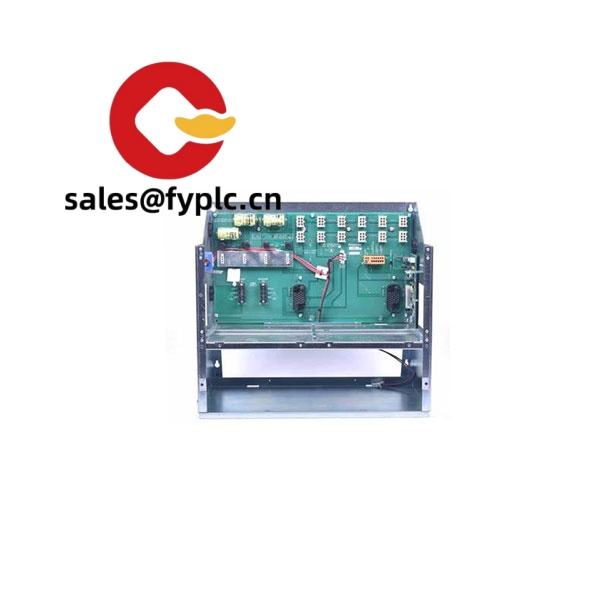

Honeywell 51404170-175 – DCS I/O Module for Experion/Series C maintenance and system expansions

The Honeywell 51404170-175 is a commonly specified spare for Experion PKS / Series C (and many mixed TDC/Experion) installations. From my experience, plants use this part to keep I/O bays healthy during upgrades and routine maintenance—especially when you want a drop-in card that preserves field wiring on the base/FTA. You might notice that it slots straight into the standard Honeywell I/O backplane, so changeover time is typically short and predictable.

Our Order Process & Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than one month at the latest

- Payment terms: 50% advance payment, full payment before delivery

- Express options: FedEx, UPS, DHL

- Pre-shipment testing and photos upon request

Key Features

- Series C/Experion compatibility – Designed for Honeywell DCS cabinets, making it a practical spare for ongoing lifecycle support.

- Backplane-powered design – Power is provided via the I/O chassis, so no extra field supply lines to manage.

- Field wiring remains on the base/FTA – Swap the module without disturbing terminal wiring, which typically keeps downtime low.

- Supports standard signal families – When paired with the matching I/O base/FTA, it’s commonly used for analog (4–20 mA/HART) or 24 VDC discrete signals.

- Service-friendly indicators – Status LEDs help technicians diagnose at a glance during commissioning or fault-finding.

- Built for industrial environments – Honeywell modules in this family are typically rated for control room conditions with good noise immunity.

Technical Specifications

| Brand / Model | Honeywell / 51404170-175 |

| HS Code | 8538.90 (Parts for switching/protection/control panels) |

| Power Requirements | 24 VDC supplied via backplane; power draw varies by revision (typical low-watt card) |

| Dimensions & Weight | Single-width Series C form factor; approx. < 0.5 kg (module only) |

| Operating Temperature | 0 to +55°C; 5–95% RH, non-condensing (control room typical) |

| Signal Input/Output Types | Depends on paired I/O base/FTA; commonly used for 4–20 mA/HART analog or 24 VDC discrete I/O in many cases |

| Communication Interfaces | Backplane interface to the controller (no external Ethernet ports on the module itself) |

| Installation Method | Installs on Honeywell I/O base/FTA within a control cabinet (DIN-rail or chassis as per Series C layout) |

Note: Different revisions of 51404170-175 exist; if you share your cabinet/BOM snapshot, we’ll match firmware and compatibility before shipment.

Application Fields

- Oil & Gas (well pads, terminals, refining I/O bays)

- Chemicals & Petrochemicals (unit interlocks, analog loops, machine permissives)

- Power Generation (balance-of-plant I/O, auxiliary systems)

- Pharmaceuticals (utilities, CIP/SIP skids, environmental monitoring)

- Pulp & Paper, Food & Beverage, Mining (general process I/O consolidation)

Advantages & Value

- Reliability – Honeywell cards in this family have a strong track record in 24/7 plants; mean-time-to-repair is short due to straightforward replacement.

- Compatibility – Designed around the Honeywell I/O ecosystem, which reduces interface risk when compared with third‑party adapters.

- Cost & downtime savings – Minimal rewiring since field terminations remain on the base/FTA, which usually trims outage windows.

- Technical support – We can pre-check part revisions and run a powered functional test; you receive traces and photos so acceptance is faster on site.

One thing I appreciate is how quickly maintenance teams can close work orders with this spare. A refinery maintenance lead told us the swap took under 20 minutes end-to-end because the field terminals weren’t touched—only the module came out and in.

Installation & Maintenance

- Cabinet & environment – Mount in a clean, ventilated control cabinet; avoid excessive vibration and corrosive atmospheres. Keep ambient within 0–55°C, RH non‑condensing.

- Wiring – Field wiring remains on the FTA/base; verify loop polarity and shield terminations. Use proper labeling to reduce commissioning slips.

- ESD & safety – De-energize the I/O segment when practical; observe ESD precautions; confirm backplane connectors are seated before powering up.

- Firmware/config – Align module firmware and controller configuration to your Experion revision. A quick node health check after insertion is usually enough.

- Routine care – Periodically inspect for dust, check status LEDs, and keep a documented spare on the shelf in sealed packaging.

Quality & Certifications

- Manufactured under ISO 9001 quality systems (Honeywell).

- CE and UL/cUL compliance typical for Series C/Experion modules.

- RoHS compliance in most revisions; we can confirm by part serial if needed.

- Supplied with a 365‑day warranty from us; OEM terms may differ by region and revision.

Reviews

There are no reviews yet.