Description

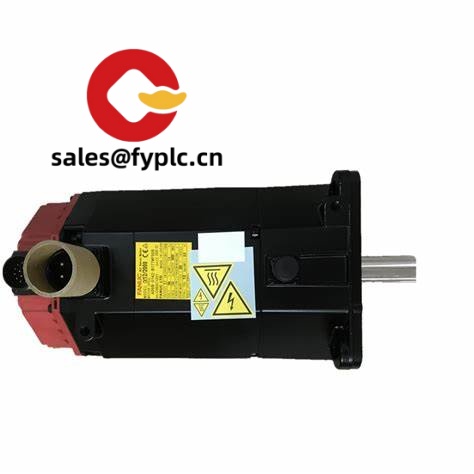

FANUC A06B-0075-B003 – Compact 200V-Class AC Servo Motor for CNC Axis Drives

The FANUC A06B-0075-B003 is a compact AC servo motor from the α-series family, designed for precise, repeatable axis motion on CNC lathes, machining centers, grinders, and automated fixtures. From my experience, this model sits in the small-to-medium torque range and integrates cleanly with FANUC α/αi servo amplifiers in 200V-class systems. You might notice that motors with the “B003” option code typically feature a straight keyed shaft and are supplied without a holding brake—ideal when you want low-inertia response without the extra brake wiring or maintenance.

Order Placement Process & Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- 200V-class AC servo design – Pairs directly with FANUC α/αi servo amplifiers for stable, low-ripple torque.

- B003 option code – Typically a straight, keyed shaft without brake, simplifying mechanics when a brake isn’t required.

- High-resolution FANUC pulse coder – Reliable position feedback for smooth contouring and tight following error.

- Low-inertia rotor – Fast acceleration/deceleration on short-stroke axes and pick-and-place units.

- Sealed construction – IP-rated at the shaft/connector area when installed with proper seals; suitable for most shop-floor environments.

- Drop-in compatibility – Common mounting/connector style across many FANUC-equipped machines, easing retrofits.

Technical Specifications

| Brand / Model | FANUC A06B-0075-B003 (AC Servo Motor, α-series) |

| HS Code | 8501.51 (AC motors, multi-phase, output not exceeding 750 W; typical classification for this frame) |

| Power Requirements | 200V-class, 3-phase power supplied via matching FANUC servo amplifier (U/V/W from amplifier to motor) |

| Signal Input/Output Types | FANUC pulse coder feedback (incremental/serial as configured), power leads U/V/W, PE ground; no brake leads on B003 |

| Communication Interfaces | Proprietary FANUC encoder interface to servo amplifier; no fieldbus on motor (handled by CNC/amplifier) |

| Installation Method | Flange mount (face mounting), straight keyed shaft, coupling or belt-driven transmission |

| Operating Temperature | 0 to 40°C ambient (non-condensing), typical FANUC α motor rating |

| Dimensions & Weight | Compact α-series frame; commonly a 90 mm square-class flange with approx. 3–5 kg mass (varies slightly by sub-variant) |

| Protection & Cooling | IP-rated at shaft/connector when sealed; natural convection cooled |

Application Fields

This motor fits linear axes and rotary indexing where tight positioning and quick reversals matter. Typical uses include:

- CNC machining centers (X/Y/Z on compact VMCs, tool changers, and rotary tables)

- Turning centers (turret indexing, sub-spindle feeds, loader axes)

- Grinders and EDM positioning stages requiring smooth low-speed creep

- Pick-and-place units and compact gantries in assembly/test automation

“We swapped in the A06B-0075-B003 on a small drill-tap center. Tuning was straightforward and the axis response improved right away, especially on short moves.” – Maintenance Supervisor, precision machining shop

Advantages & Value

- Reliability you can plan for – FANUC α motors are known to run for years with minimal drift or noise.

- Compatibility – Directly replaces similar α/αi 200V-class small-frame motors; cable/connector styles are standardized in many cases.

- Total cost of ownership – Stable spares availability and predictable service paths reduce unplanned downtime costs.

- Support-ready – Easy parameter matching with FANUC CNCs and amplifiers keeps commissioning time short.

Installation & Maintenance

- Mounting and alignment – Use the flange pilot for concentricity; align couplings to minimize radial/axial load on front bearings.

- Wiring – Route U/V/W power and encoder cables separately to reduce noise; ensure proper PE ground and strain relief.

- Environment – Keep within 0–40°C ambient and avoid coolant spray without proper sealing; allow airflow for natural cooling.

- Safety – Lock out/tag out before service; verify insulation resistance if the motor has been in storage.

- Routine checks – Inspect connectors/seals, listen for bearing noise at low RPM, and keep the housing clean of chips and dust.

- Encoder considerations – If your system uses an absolute reference, maintain the CNC’s backup battery so position data isn’t lost.

Quality & Certifications

- Conformity: CE marking, UL Recognized, and RoHS compliance in most shipments

- Manufacturing standards: Produced under ISO-certified quality systems

- Warranty: 365-day warranty coverage as stated above

If you’re replacing an existing unit, sharing your amplifier model and axis data helps confirm encoder optioning and cable compatibility. One thing I appreciate about this motor is how predictable it is to commission—most of the time, it’s set the parameters, tune the loop, and you’re cutting chips again.

Reviews

There are no reviews yet.