Description

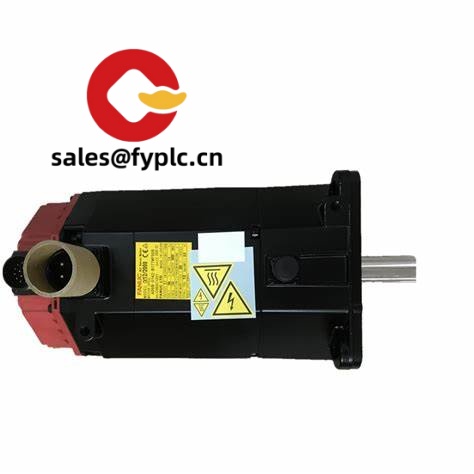

FANUC A06B-0243-B100 AC Servo Motor – Reliable α-series drive for CNC axes and precision motion

The FANUC A06B-0243-B100 is a compact α-series AC servo motor widely used on CNC machine tools and automated production lines. From my experience, this format is chosen when you need smooth 3000‑rpm class operation, tight position control, and straightforward compatibility with FANUC servo amplifiers. The “B100” option typically indicates a straight, keyed shaft without a holding brake, making it a good fit for feed axes where the amplifier handles dynamic holding. You might notice that it drops into existing FANUC cabinets with minimal fuss, which saves setup time and reduces the risk of unforeseen wiring changes.

Our Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery time: 1 week for in-stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express delivery: FedEx, UPS, DHL

- Each unit is function-tested and packed for industrial transit

Key Features

- FANUC α-series compatibility – Typically pairs with FANUC α/αi Servo Amplifier Modules for seamless commissioning.

- Straight keyed shaft (B100) – Standard keyed shaft simplifies coupling to ball screws or gearboxes; usually supplied without a brake.

- High-resolution serial pulse coder – Stable position feedback to the amplifier for precise contouring and smooth low-speed motion.

- Compact, robust construction – A good fit for dense control cabinets and machine frames; in many cases, no special cooling is required.

- 200–230 VAC class supply via drive – Runs off the matched FANUC servo amplifier’s output; wiring remains straightforward (U/V/W + encoder).

- Industrial protection – Typically IP65 at the shaft end with oil seal when properly mated; suitable for shop-floor environments.

- Service-friendly – Standard FANUC connectors and labeling help reduce downtime during swaps.

Technical Specifications

| Brand / Model | FANUC A06B-0243-B100 (α-series AC servo motor) |

| HS Code | 8501.51 (AC multi-phase motor, >37.5 W and ≤750 W), typically used for this power class |

| Power Requirements | 3-phase 200–230 VAC class via matched FANUC servo amplifier (U/V/W output from drive) |

| Rated Speed (series) | 3000 rpm class (typical for the A06B-024x α-series range) |

| Signal I/O Types | Power: U/V/W; Feedback: FANUC serial pulse coder (incremental/absolute handling by the amplifier) |

| Communication Interfaces | Motor-to-drive serial encoder link; no fieldbus on the motor itself |

| Shaft / Brake | B100: straight keyed shaft; standard build is without holding brake |

| Protection & Cooling | IP65 at shaft end with seal (typ.); natural convection cooling |

| Operating Temperature | 0–40°C ambient, ≤85% RH non‑condensing recommended |

| Installation Method | Flange mount (footless), horizontal or vertical; align to coupling and observe runout tolerances |

| Compatible Drives | FANUC α/αi Servo Amplifier Modules of matching capacity (e.g., A06B-6079 / A06B-6117 families, depending on axis sizing) |

Application Fields

This motor sees regular duty on CNC machining centers, lathes, and EDM positioning axes. It’s also used in electronics assembly, packaging machinery, and light robotics where fast indexing and repeatable accuracy matter. One customer running a small vertical machining center mentioned a noticeable improvement in surface finish after swapping to a fresh A06B-0243-B100 and performing a quick servo tuning on the amplifier—it seems to help with micro-interpolation stability in many cases.

Advantages & Value

- Reliability – FANUC α-series motors are known for long service life and predictable thermal behavior.

- Compatibility – Drop-in with FANUC amplifiers and CNCs reduces commissioning risks and software changes.

- Cost control – A like-for-like replacement shortens downtime and avoids re-engineering of mounts and cables.

- Technical support – Assistance with parameter checks, encoder orientation, and run-in is available upon request.

Installation & Maintenance

- Cabinet & environment – Keep the drive in a ventilated enclosure; maintain ambient 0–40°C. Protect the motor from coolant ingress; use sealed connectors.

- Mounting – Clean the mounting face, align carefully to minimize coupling misalignment. Check key fit on the shaft and observe runout tolerances.

- Wiring – Route power (U/V/W) and encoder cables separately to reduce noise. Confirm grounding and shield termination at the drive end.

- Safety – Lock out the amplifier before wiring. If a brake-equipped variant is used, verify 24 VDC brake control on the I/O.

- Routine care – Periodically inspect connectors and seals, clean dust buildup, and verify encoder counts after any mechanical work. Firmware/parameter backups on the CNC help during swaps.

Quality & Certifications

- Typically supplied with CE conformity; many FANUC motors also carry UL markings depending on build

- RoHS compliance applies to later production batches

- Warranty: 12 months (365 days) from delivery

- Each unit is tested for insulation resistance, encoder communication, and phase balance before shipment

Reviews

There are no reviews yet.