Description

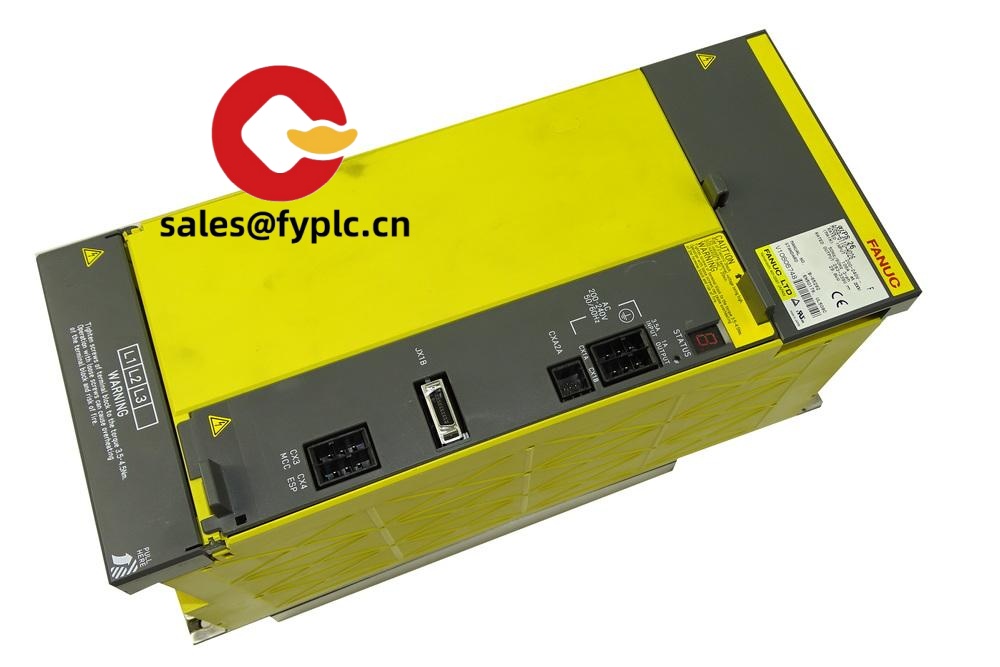

FANUC A06B-6110-H026 (PSM-26H) – Power Supply Module for αi Servo/Spindle Systems

The FANUC A06B-6110-H026, commonly known as the PSM-26H, is a power supply module designed for FANUC αi-series drives. From my experience, it’s a dependable backbone for medium-to-large CNC machines where stable DC bus power and regenerative handling are critical. It feeds the αi servo and spindle amplifier stack, keeps energy recovery under control, and usually drops in with minimal commissioning if you’re replacing an existing unit on the same system.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week for in-stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express: FedEx, UPS, DHL

Key Features

- Purpose-built for FANUC αi systems – Works with αi servo (A06B-6114-xxxx) and spindle amplifiers (A06B-6111/A06B-6117-xxxx) to supply a stable DC link.

- 3-phase 200–240 VAC input – A practical range for most machine tool plants; typically supports 50/60 Hz mains.

- Regenerative energy control – Handles braking energy; external resistor units can be added where required by inertia/load.

- Compact, cabinet-ready form factor – Vertical panel mounting with top/bottom airflow, easy busbar and CN connections.

- Service-friendly indicators – Clear status/alarm display helps maintenance teams diagnose issues quickly on the shop floor.

- Proven reliability in CNC environments – In many cases, these units run for years with only periodic cleaning and checks.

Technical Specifications

| Brand / Model | FANUC A06B-6110-H026 (PSM-26H) |

| HS Code | 8504.40 (Electrical static converters) |

| Power Requirements | 3-phase 200–240 VAC, 50/60 Hz input; provides DC bus for αi servo/spindle modules |

| Operating Temperature | 0 to +55 °C, non-condensing (typical for cabinet-mounted FANUC drive hardware) |

| Signal I/O Types | DC link outputs (P/N), regen terminals, control connector (CN) for status/ready; 24 VDC auxiliary as applicable |

| Communication Interfaces | None directly; FSSB/comm is handled by the servo/spindle amplifiers in the αi system |

| Installation Method | Vertical panel mounting inside a control cabinet with forced-air ventilation and proper clearances |

| Dimensions & Weight | Approx. 380 × 150 × 300 mm; ~12–14 kg (varies slightly by revision—confirm before panel layout) |

Application Fields

Typically found in CNC machining centers, turning centers, grinders, EDM lines, and automated cells using FANUC αi drives. You might notice that retrofit teams prefer the A06B-6110-H026 on medium-inertia applications where a robust DC bus and reliable regen are important, especially with multi-axis servo stacks and αi spindle combinations.

- Metal cutting and forming (MC/TC/HMC/VMC)

- Automotive and aerospace machining lines

- Robotics cells with integrated machine tools

- General-purpose industrial automation using FANUC αi drives

Advantages & Value

- Reliability that reduces unplanned downtime – One maintenance lead told us they swapped in an A06B-6110-H026 and were back cutting parts in under two hours.

- Seamless compatibility – Designed for αi servo/spindle stacks; wiring, busbars, and CN connectors match the FANUC ecosystem.

- Cost control – In many cases, replacing the PSM restores a whole drive group without changing motors or amplifiers.

- Technical backing – We can help confirm pairing with αi servo amps (A06B-6114-xxxx), spindle amps (A06B-6111/A06B-6117-xxxx), and regen units when the load requires it.

Installation & Maintenance

- Cabinet setup – Mount vertically on a rigid backplate; keep intake/exhaust paths clear. Good practice is filtered, forced-air cooling with ambient typically ≤ 40–45 °C for longevity.

- Power wiring – Use the correct 3-phase supply, protective earth, and MCCB/fuse ratings per FANUC guidelines. Tighten busbar and terminal torque to spec.

- DC link and regen – Connect P/N to the αi amplifier stack; verify external braking resistor specs if your inertia/load profile demands it.

- EMC and grounding – Star-grounding and clean cable routing reduce noise issues; keep power and signal lines separated where possible.

- Routine care – Periodic dust removal, fan/filter checks, and visual inspection of terminals and capacitors. If stored long-term, capacitor reforming is recommended before full load.

- Firmware – The PSM itself typically has no field-upgradable firmware; any updates usually relate to servo/spindle amplifiers and CNC software.

Quality & Certifications

- Certifications: typically CE-marked; UL Recognized; RoHS compliance depending on revision

- Manufacturing quality: FANUC production under ISO 9001 environments

- Warranty: 365-day coverage as stated above

Related Components (for a complete stack)

- Servo Amplifiers: FANUC A06B-6114-xxxx (αi SVM series)

- Spindle Amplifiers: FANUC A06B-6111 / A06B-6117-xxxx (αi SPM series)

- Braking/Regenerative Options: External resistor units where required by load

- Motors: FANUC αi series servo and spindle motors matched to the amplifier ratings

Reviews

There are no reviews yet.