Description

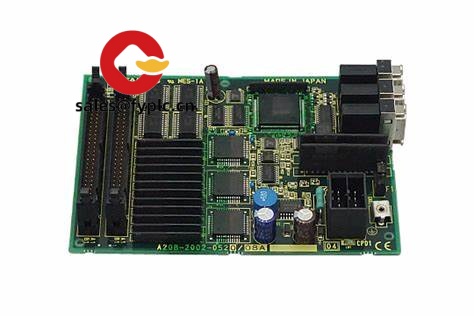

FANUC A20B-2101-0390 CNC Control PCB – OEM Replacement Board for FANUC CNC Systems

The FANUC A20B-2101-0390 is an original FANUC printed circuit board used inside FANUC CNC control cabinets. From my experience, it’s the kind of board you install when you need a clean, drop‑in replacement to bring a machine back online without rewiring or reengineering around third‑party parts. You might notice that the connector layout and keying match the rack positions exactly—this typically makes swap‑outs straightforward, especially during unplanned downtime.

Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

- Packing: ESD-safe packaging with foam cushioning, suitable for international transit

- Testing: Boards are function-tested before dispatch in most cases

Key Features

- OEM form‑fit compatibility – Designed to seat directly in the FANUC CNC rack/backplane with keyed connectors.

- Backplane-powered logic – Typically draws 5 VDC logic power via the CNC backplane; no external field wiring to the board face.

- Stable operation – Built for continuous industrial duty in enclosed control cabinets, which in many cases reduces intermittent faults caused by vibration.

- Service-friendly – Clear connector orientation and captive hardware help technicians complete a board swap in minutes.

- Traceable part identity – Part number and revision markings make compatibility checks and maintenance history easier.

Technical Specifications

| Brand / Model | FANUC A20B-2101-0390 |

| HS Code (HS6) | 853890 (Parts for electrical control equipment) |

| Power Requirements | Backplane-supplied; typically 5 VDC logic rail from the CNC power system |

| Form Factor & Mounting | Plug-in PCB for FANUC CNC rack; single-slot board, secured with captive fasteners |

| Operating Temperature | 0 to 55°C cabinet ambient (non‑condensing), typical for FANUC control cabinets |

| Signal I/O Types | Internal digital bus via backplane; board-edge keyed connectors as per control configuration |

| Communication Interfaces | FANUC proprietary backplane interface; no user-accessible fieldbus ports on the board face (in most cases) |

| Installation Method | Rack-mounted inside CNC cabinet; ESD-safe handling; align and insert straight into the backplane |

Application Fields

This board is used within FANUC CNC control systems across:

- CNC machining centers and turning centers

- Grinding, EDM, and precision milling equipment

- Automated production lines and transfer machines with FANUC controls

- Retrofit or maintenance replacement in existing FANUC racks

One thing I appreciate is how these boards help standardize maintenance across mixed-machine shops. A customer running two lathes and a vertical mill told us the swap took under 20 minutes with normal lockout/tagout—no cabinet rework, just careful seating and a quick power‑on test.

Advantages & Value

- Reliability – OEM component quality that, in many cases, runs for years in continuous duty.

- Compatibility – Form‑fit, backplane-matched; avoids trial-and-error typical with non‑OEM options.

- Reduced Downtime – Fast availability and simple installation get machines cutting again sooner.

- Cost Control – Prevents cascading repairs caused by mismatched boards or connector damage.

- Technical Support – We assist with part verification by photos/labels to confirm fit before shipment.

Installation & Maintenance

- Environment – Install inside a sealed CNC cabinet with adequate ventilation. Keep filters clean to maintain airflow.

- Power-down best practices – Shut down the CNC, isolate mains, and wait for DC bus discharge. Handle the PCB by the edges with an ESD strap.

- Seating and fasteners – Align evenly and press straight into the backplane; tighten captive screws to the manufacturer’s feel—don’t over-torque.

- Wiring – Only reconnect designated ribbon/edge connectors; avoid strain on cables and check for bent pins.

- Routine care – Quarterly light cabinet cleaning (dry air, low pressure) to reduce dust; confirm fan/filter status.

- Software & backups – After replacement, verify system boots normally. It appears that keeping recent parameters/backups is helpful if the control requires reinitialization.

Quality & Certifications

- CE compliance for EMC when installed inside a compliant CNC cabinet (typical for FANUC control assemblies)

- RoHS conformity on many production lots; we can confirm by part label if needed

- Manufactured under ISO 9001 quality systems at the OEM level

- Warranty: 365 days from delivery

Notes on Compatibility

The A20B-2101-0390 sits within a defined control family. Actual slot position and board role may vary by machine model and control generation. If you share a photo of the current label set (including any suffix/revision), we’ll double‑check the match to your CNC before shipping—this typically avoids avoidable returns and gets you a confirmed drop‑in unit.

Reviews

There are no reviews yet.