Description

ABB AGPS-11C – Compact Power Supply Module for Industrial Control Cabinets

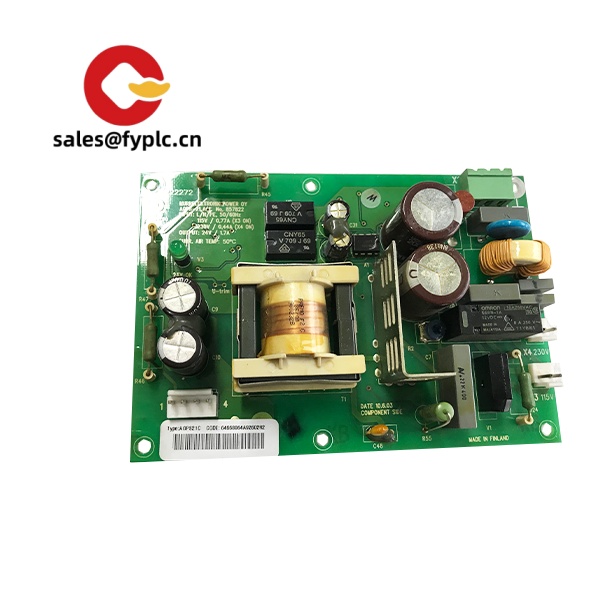

The ABB AGPS-11C is a compact industrial power supply module designed to stabilize and distribute DC power inside automation cabinets. From my experience, it’s typically used to feed control electronics and I/O backplanes in ABB-based systems, where clean, reliable DC power is critical for uptime. You might notice that its footprint suits tight cabinets and retrofit jobs, which is helpful when you’re replacing like-for-like parts without reworking rack layouts.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Stabilized DC output for control electronics – Delivers clean power to control boards and I/O backplanes to reduce nuisance trips.

- Cabinet-friendly form factor – A plug-in module profile that typically fits ABB control racks, making field replacement straightforward.

- Protection and diagnostics – Overload/short-circuit protection and front status indication in many cases, so technicians can quickly verify health.

- Noise immunity – Designed for industrial environments with switching loads and VFDs; helps maintain stable voltage under electrical noise.

- Redundancy-ready architecture – Often used in dual-feed power architectures to maximize availability on critical lines.

- Serviceability – Tool-light access and predictable replacement routine; typically no firmware handling required.

Technical Specifications

| Brand / Model | ABB AGPS-11C |

| HS Code | 8504.40 (Static converters / power supplies) |

| Power Requirements | Typically 24 VDC nominal input (industrial control power); stabilized DC output to system backplane |

| Dimensions & Weight | Compact plug-in module; 1-slot style footprint; light enough for single-person handling |

| Operating Temperature | Typically 0 to +55 °C for cabinet-mounted modules (non-condensing) |

| Signal I/O Types | Power distribution only; no process signal I/O |

| Communication Interfaces | None (status indication locally on the module where applicable) |

| Installation Method | Rack/backplane plug-in within an ABB control cabinet; wiring via cabinet DC distribution |

Application Fields

The AGPS-11C fits maintenance and expansion tasks across process automation where ABB control platforms are deployed. Typical scenarios include:

- Powering I/O racks and controller backplanes in DCS/PLC cabinets

- Redundant DC feed setups for continuous process lines in chemicals, water, and power

- MRO spare for fast recovery after a cabinet power fault or aging supply failure

- Retrofit projects where form/fit compatibility reduces cabinet rework

A maintenance supervisor at a midstream facility told us the AGPS-11C “dropped into the existing rack and we were back online in under 30 minutes,” which seems to be a common theme with these compact ABB supplies.

Advantages & Value

- Reliability in harsh cabinets – Stable DC rails help avoid nuisance controller resets and intermittent I/O faults.

- Compatibility – Form factor and wiring approach are geared for ABB control cabinets, cutting engineering time during replacement.

- Lower downtime cost – Fast swap-over and clear status indication can shorten mean time to repair.

- Support – Application guidance and pre-shipment testing available to match your cabinet power design.

Installation & Maintenance

- Cabinet environment – Mount in a clean, dry control cabinet (IP54 or better recommended). Provide airflow paths; avoid placement near high-heat drives without baffles.

- Power wiring – Use correctly sized DC conductors and ring/fork terminals; verify protective earth continuity. In most cases, a 24 VDC UPS and surge protection improve availability.

- Redundancy – For A/B feed architectures, isolate returns and use OR-ing or redundancy modules as specified by your cabinet design.

- Safety – De-energize sources and lock out before removal or insertion. Check residual voltage on capacitors.

- Routine checks – Quarterly visual inspection for dust and loosened terminals; annual verification of output stability and ripple. Clean with dry air; avoid solvents.

- Lifecycle notes – Electrolytic capacitors age; many plants plan proactive replacement at 7–10 years depending on load and temperature.

Quality & Certifications

- CE compliant for industrial environments

- RoHS conformity for hazardous substances

- UL/CSA recognition for control equipment, where applicable

- Manufacturer-grade build and traceability; warranty: 365 days from shipment

Helpful Accessories (typical)

- 24 VDC UPS module for ride-through on brownouts

- DIN-rail surge protection for DC circuits

- Labeling and circuit identification sets for cabinet maintenance

Reviews

There are no reviews yet.