Description

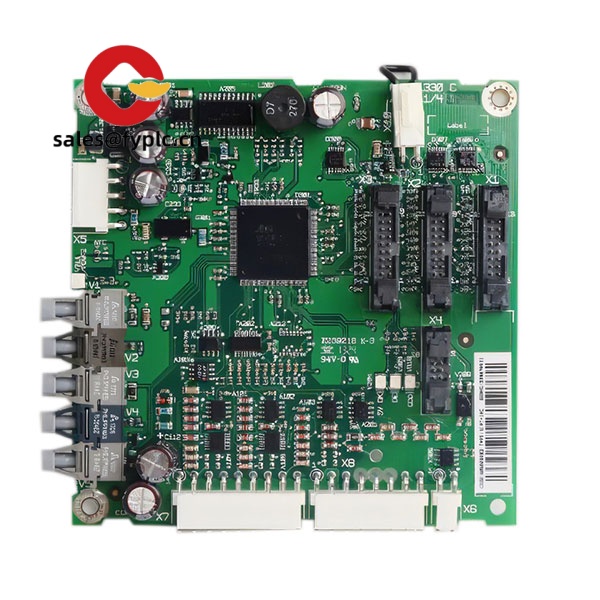

ABB AIO2881 Mixed Analog I/O Module – Reliable AI/AO for Industrial Control Cabinets

The ABB AIO2881 is a mixed analog input/output module designed for cabinet-mounted automation systems where stable, noise-immune analog signals really matter. From my experience, it’s typically used to terminate 4–20 mA loops and 0–10 V signals in DCS/PLC racks, allowing you to read process variables and drive control outputs from the same card. You might notice that it fits best in plants standardizing on ABB architectures, especially when maintenance prefers fast module swaps and clean backplane integration rather than standalone signal conditioners.

Our Order Placement Process and Guarantees

- Warranty: 365 days coverage

- Lead time: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance; balance due prior to delivery

- Shipping: FedEx, UPS, DHL express options available

- Packaging: Anti-static, shock-resistant packing for control modules

- Traceability: SN/lot recorded on documents for maintenance records

Key Features

- Mixed analog I/O on one module: Combines analog inputs and outputs to simplify cabinet layout and spares management.

- Typical industrial signal ranges: Supports 4–20 mA and 0–10 V (input/output), suitable for transmitters, drives, valves, and positioners.

- Galvanic isolation: Channel-to-bus isolation helps reduce ground loops and noise in long cable runs.

- Backplane integration: Plugs into the ABB rack/backplane, so no extra gateway wiring or external power bricks in most cases.

- Diagnostics LEDs/status bits: Basic health, power, and channel diagnostics that speed up commissioning and fault tracing.

- Stable in industrial environments: Designed for control cabinets with appropriate shielding and grounding practices.

Technical Specifications

| Brand / Model | ABB AIO2881 |

| HS Code | 853890 — Parts suitable for electrical control apparatus |

| Power Requirements | Typically 24 VDC via backplane; module consumption in the low single-digit watts |

| Dimensions & Weight | Single-slot rack/din format; compact module footprint suitable for standard control cabinets |

| Operating Temperature | Typically 0 to +55 °C for cabinet environments (non-condensing) |

| Signal Input/Output Types | Analog inputs: 4–20 mA, 0–10 V; Analog outputs: 4–20 mA, 0–10 V (channel assignment by configuration, depends on system) |

| Communication Interfaces | Backplane bus integration to host controller (no external fieldbus on the module itself) |

| Installation Method | Rack/backplane plug-in; wiring via front terminal base or plug-in terminal block (system dependent) |

Application Fields

Plants with a mix of pressure, flow, level, and temperature loops usually go for modules like the AIO2881. It’s a solid fit in:

- Process industries: chemicals, oil & gas, water/wastewater (4–20 mA transmitters and control valves)

- Manufacturing: metals, pulp & paper, glass (0–10 V analog drive references and feedback)

- Utilities and building systems: boiler rooms, district energy, HVAC plants

- Material handling: analog position feedback and actuator control in conveyors and stackers

Advantages & Value

- Fewer modules to stock: Mixed AI/AO on one card reduces spares inventory and cabinet space.

- Straightforward replacement: In most cases, a hot-swap or quick swap with retained configuration via the controller saves downtime.

- Noise-resistant design: Proper isolation and grounding typically minimize signal drift and interference on long runs.

- Works within ABB ecosystems: Seamless backplane integration means less time wiring interfaces and more time commissioning.

- Total cost of ownership: Lower wiring density and simplified maintenance often translate to real OPEX savings.

Installation & Maintenance

- Cabinet standards: Mount in a clean, ventilated cabinet (typically IP54 or better). Keep ambient within the stated temperature range.

- Wiring: Use shielded twisted pairs for analog signals; ground shields at one point only to avoid loops. Separate analog from power cables.

- Power & grounding: Stable 24 VDC bus and a low-impedance cabinet ground usually yield the best noise performance.

- Commissioning tips: Verify input scaling (mA vs V), output ranges, and any filtering or damping in the controller.

- Routine maintenance: Periodic loop checks and zero/span verification annually; clean terminal area to remove dust; review firmware/controller revisions when planning shutdowns.

- Safety: De-energize the rack before inserting/removing modules unless the system supports hot-swap and site procedures allow it.

Quality & Certifications

- CE compliant; RoHS-conformant design

- UL/CSA recognition is typical for ABB control modules

- Manufactured under ISO 9001 quality systems

- Backed by a 365-day warranty (repair/replace terms)

Compatible Accessories & Supporting Components

- Backplane/rack unit for ABB I/O systems

- Plug-in terminal bases or front connectors with labeling strips

- Shielded cable glands and grounding kits for low-noise analog wiring

- Surge protection modules for field loops in harsh environments

A maintenance lead at a metals plant told us the mixed I/O approach “seems to be the sweet spot” for small skids: one module per skid, easy to replace, and no guesswork with signal conditioners. That matches what we typically see in brownfield upgrades.

Reviews

There are no reviews yet.