Description

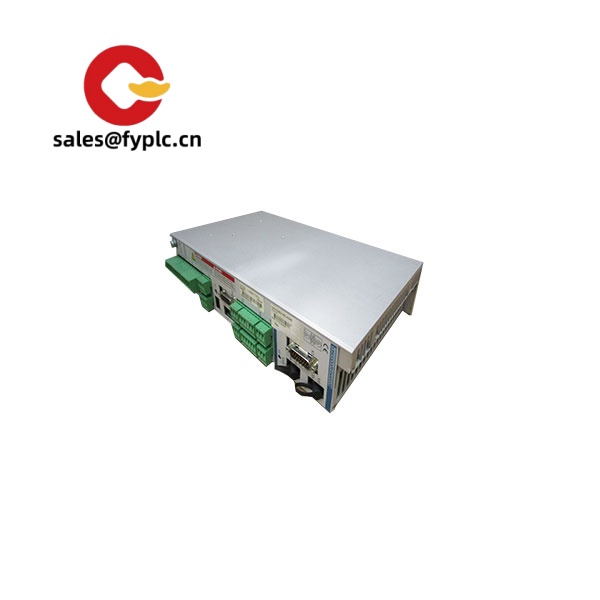

ABB AO650 (3BHT300051R1) – Analog Output Module for Precise Current Loop Control in DCS/PLC Systems

The ABB AO650, part number 3BHT300051R1, is an industrial analog output module designed for ABB distributed control and automation platforms. From my experience, it’s typically used where you need stable 4–20 mA control signals to drive control valves, VFD reference inputs, I/P converters, or panel indicators. It seems to be a favorite in brownfield upgrades because it slots into existing ABB I/O infrastructure with minimal wiring changes.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week for in‑stock items; no more than one month at the latest

- Payment terms: 50% advance payment; full payment before delivery

- Express delivery: FedEx, UPS, DHL

- Packaging & traceability: anti‑static packing with full test records available on request

Key Features

- Industrial analog current outputs – typically used for 4–20 mA control loops in process applications.

- Stable and low‑noise output design – helps maintain tight control on valves and drives, especially under load changes.

- Backplane powered – draws power from the ABB I/O rack/terminal unit; wiring stays tidy and serviceable.

- Channel isolation and diagnostics – in many cases, channel and system isolation reduce ground loops; built‑in status indications assist troubleshooting.

- Compatible with ABB DCS/PLC platforms – used across ABB process automation systems where AO modules are required.

- Hot maintenance workflow – many installations allow module replacement during planned maintenance with minimal loop disruption.

Technical Specifications

| Brand / Model | ABB AO650 – 3BHT300051R1 |

| HS Code | 8538.90 (Parts suitable for apparatus of heading 8537) |

| Power Requirements | Supplied via system backplane (24 VDC nominal from rack power supply, typical) |

| Signal Output Types | Analog current outputs for process control (commonly 4–20 mA ranges) |

| Communication Interfaces | Proprietary ABB I/O backplane interface to the controller or I/O bus coupler |

| Installation Method | Plug‑in module on ABB I/O rack/terminal base; DIN‑rail or cabinet rack according to system design |

| Operating Temperature | 0 to +55 °C (typical for ABB I/O modules; verify per site standard) |

| Dimensions & Weight | Compact ABB rack module format; designed for high‑density control cabinets |

Note: Exact channel count and detailed electrical data can vary by system revision and firmware. We can match to your installed base if you share the controller type and I/O rack/terminal unit.

Application Fields

- Process industries: refining, chemical, petrochemical – valve positioners, flow controllers, pressure control I/Ps.

- Power & utilities – feedwater and combustion control loops, turbine auxiliary systems.

- Water & wastewater – dosing pumps, blower/VFD speed reference signals.

- Pulp & paper, mining, and metals – actuator references and analog panel instrumentation.

One thing I appreciate is how predictable the loop behavior is when you pair AO modules like this with shielded twisted pair wiring and proper grounding. You might notice fewer nuisance trips in noisy environments when the cabinet layout is done right.

Advantages & Value

- Reliability: ABB’s process I/O modules are known for long service life and strong temperature stability.

- Compatibility: Fits ABB control architectures that specify AO650, cutting project risk during migrations.

- Cost savings: Reusing existing racks/terminal bases, in many cases, avoids new wiring and reduces downtime.

- Technical support: We can help verify firmware, revision matching, and loop characteristics before shipment.

A maintenance lead at a chemical plant told us their primary win was “repeatable valve tuning.” After swapping to matched AO modules across a unit, their PID loop tuning stabilized and callouts dropped by half. That’s the kind of incremental gain buyers usually look for.

Installation & Maintenance

- Cabinet standards: Mount on ABB‑specified rack/terminal unit inside a ventilated control cabinet; allow airflow around power supplies and I/O.

- Wiring practices: Use shielded twisted pair for 4–20 mA loops; ground shields at one end to avoid ground loops; separate signal and power wiring.

- Power & backplane: Ensure stable 24 VDC to the rack; check keying/slotting to match AO650 to the correct terminal base.

- Safety: Isolate loops before inserting/removing modules; verify loop current is not driving field devices unexpectedly.

- Routine maintenance: Periodic loop checks and output calibration (as per site QA); clean dust with dry air; review firmware/diagnostics during turnarounds.

- Spare strategy: Keep at least one tested spare per cabinet or unit operation; align revisions for seamless swap‑out.

Supporting Components & Integration Tips

The AO650 works on its designated ABB I/O rack/terminal base and communicates through the system backplane to the controller or I/O bus coupler. If you’re planning a refresh, consider the following accessories to streamline commissioning:

- Appropriate ABB terminal unit/base for the AO650 series, with keying pins to prevent slot mismatch.

- Shielded terminal blocks and ferrules for clean analog terminations.

- Redundant 24 VDC power supplies and health monitoring to stabilize the backplane.

- Loop isolators or surge protection on field side where transients are common.

Share your controller model and I/O rack details and we’ll confirm the exact terminal base, firmware compatibility, and any keying requirements for AO650 (3BHT300051R1).

Quality & Certifications

- CE compliant (EMC and LVD, typical for ABB industrial I/O)

- UL/CSA recognition for control equipment (region dependent)

- RoHS conformity

- Manufactured under ISO 9001 quality systems

If you want us to match an installed base exactly, send the controller type, rack/terminal unit reference, and desired output range per loop. We’ll align the AO650 (3BHT300051R1) configuration to your site standard and confirm ship‑ready stock with the lead time mentioned above.

Reviews

There are no reviews yet.