Description

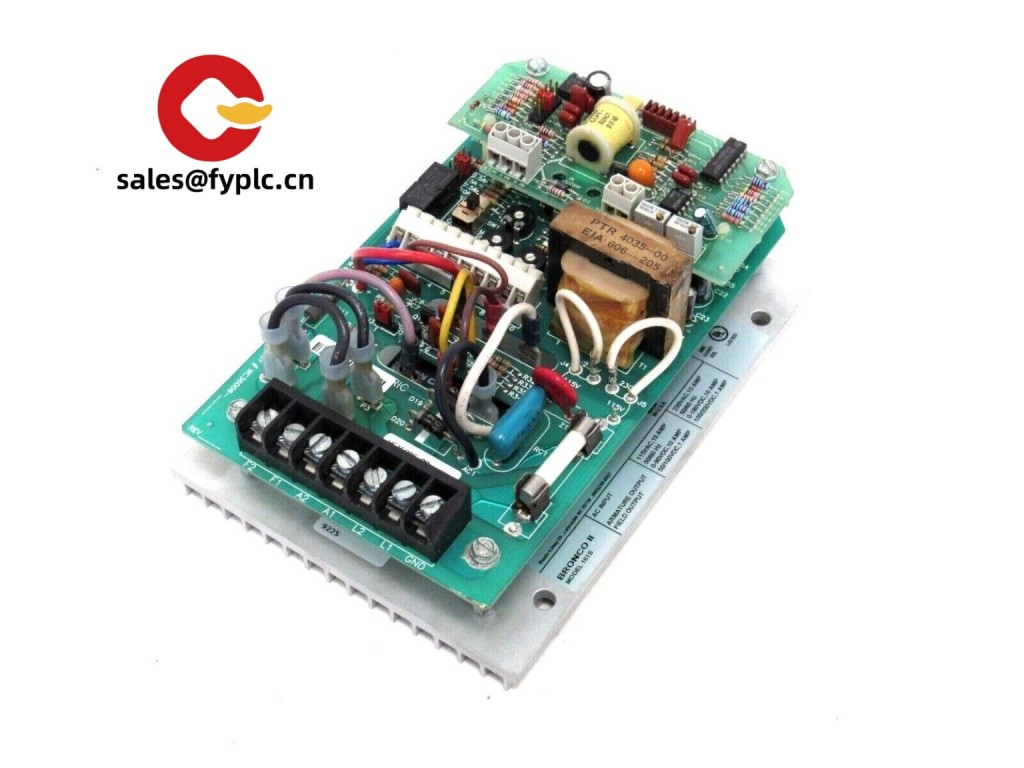

Aerotech BAI20-320 – High-voltage servo amplifier for demanding single‑axis motion

The Aerotech BAI20-320 is a robust, cabinet‑mount servo amplifier designed for 200–240 VAC systems where a 320 VDC bus is preferred. From my experience, it’s typically paired with an analog motion controller (±10 V command) to drive high‑performance industrial servomotors on stages, gantries, and precision tooling. One thing I appreciate is how predictable it feels under load—stable torque delivery and straightforward protection make it pragmatic for upgrades or field replacements.

Our Order Process & Guarantees

- Warranty: 365 days

- Lead time: 1 week when in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Courier options: FedEx, UPS, DHL

Key Features

- 320 VDC bus for high dynamic response – Built for 200–240 VAC mains, enabling fast torque rise and high speed ranges.

- 20 A class output – Suitable for medium‑to‑high power axes; typically supports 20 A peak with application‑dependent continuous ratings.

- Analog ±10 V command interface – Plays nicely with A3200/Ensemble‑style controllers and other analog motion controls.

- Incremental encoder and Hall commutation support – Differential A/B/Z feedback and Hall inputs for brushless motor commutation.

- Comprehensive protections – Over‑current, over‑voltage, and over‑temperature fault handling to protect drive and motor.

- External dynamic braking support – Works with a properly sized brake resistor for rapid deceleration energy management.

- Cabinet‑mount chassis – Straightforward panel installation with standard industrial wiring practices.

Technical Specifications

| Brand / Model | Aerotech BAI20-320 |

| HS Code | 8504.40 (Static converters / servo drives) |

| Power Requirements | 200–240 VAC, 50/60 Hz input; internal DC bus approx. 320 VDC (typical) |

| Output / Current Class | 20 A class (peak); continuous current depends on heat sinking and duty cycle |

| Operating Temperature | 0 to +40 °C (typical cabinet environments) |

| Signal I/O Types | ±10 V analog command; differential A/B/Z encoder; Hall inputs; enable/fault digital I/O |

| Communication Interfaces | Analog interface (no embedded fieldbus; integrates with external motion controllers) |

| Supported Motor Types | 3‑phase brushless servo motors (rotary or linear); brushed DC support may be available by configuration |

| Installation Method | Panel/cabinet mount; vertical orientation; forced‑air cooling recommended |

| Protections | Over‑current, over‑voltage, over‑temperature, short‑circuit; brake resistor support |

Application Fields

You might notice this model in equipment that needs crisp servo behavior at higher bus voltages. Typical uses include:

- Precision stages and gantries in electronics assembly and inspection

- Laser processing and micromachining axes where fast settling is valuable

- Packaging, labeling, and converting lines with high‑speed indexers

- Lab automation, test fixtures, and general mechatronics retrofits

A packaging OEM recently swapped a legacy axis for a BAI20-320 and kept the existing ±10 V controller. The commissioning felt routine—just encoder phasing, gain tuning, and a properly sized braking resistor—no surprises.

Advantages & Value

- Reliability in production – Protective features and a conservative power stage help reduce unplanned stops.

- Controller‑agnostic – Accepts standard ±10 V commands; easy to drop into mixed‑vendor systems.

- Lifecycle flexibility – In many cases, a practical replacement for older high‑bus analog drives without re‑architecting control.

- Lower integration effort – Familiar wiring patterns (encoder, Hall, enable) and standard cabinet practices save engineering hours.

- Total cost – Using a single‑axis amplifier can be more economical than migrating to a full multi‑axis rack when only one axis needs service.

Installation & Maintenance

- Cabinet & cooling – Mount on a flat metal backplate; maintain vertical airflow. Provide adequate clearance and forced‑air cooling for continuous load.

- Power wiring – Use appropriately rated copper conductors, upstream fusing, and an EMI/RFI line filter on the mains as needed.

- Motor/feedback cabling – Shielded, low‑capacitance motor cables; differential encoder wiring (RS‑422 levels) with proper grounding to minimize noise.

- Braking resistor – Size an external resistor for your inertia and decel rates; ensure safe mounting and thermal clearance.

- Grounding – Single‑point protective earth; bond panel door and cable shields per IEC 61800‑3 practices.

- Commissioning – Verify phasing, Hall alignment, and loop gains at low speed first; then ramp to application speeds while monitoring faults and temperatures.

- Routine checks – Inspect connectors, fan airflow, and dust buildup quarterly; re‑verify tuning after mechanical changes or motor swaps.

Quality & Certifications

- Manufacturer certifications typically include CE and RoHS; UL/CSA recognition is common for this class of amplifier.

- Warranty provided: 365 days from delivery.

Complementary Components We Can Supply

- Braking resistor assemblies – Proper wattage/ohmic selection for the BAI20-320 bus.

- Mains line filters and line reactors – To meet EMC and improve bus stability on weak grids.

- Shielded motor and encoder cable sets – Pre‑terminated harnesses for fast, clean wiring.

- 24 V control power supplies – For enable/logic circuits where external control power is preferred.

- Analog motion controllers – ±10 V command controllers compatible with Aerotech‑style servo loops.

- Matched servomotors – Rotary or linear brushless motors sized to the 20 A class.

If your application involves aggressive decel profiles or high reflected inertia, it seems to be worth sizing the brake resistor early; in many cases that’s what unlocks stable, repeatable throughput without nuisance over‑voltage trips.

Reviews

There are no reviews yet.