Description

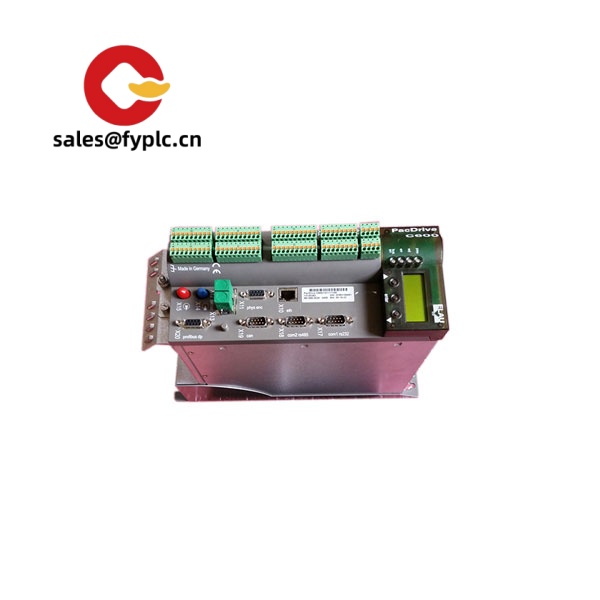

ELAU C600101100 PacDrive Controller – Central Motion/Logic Control for High‑Speed Packaging Lines

The ELAU C600101100 is part of the PacDrive C600 controller family, designed to coordinate high‑speed motion and machine logic in packaging equipment, pick‑and‑place systems, and format‑change machines. From my experience, it’s the “brain” that synchronizes multi-axis motion over a SERCOS fiber-optic ring while running IEC 61131‑3 PLC code for machine sequencing. If you’re maintaining an installed PacDrive line, this model is typically a drop‑in controller that keeps existing drives, I/O, and recipes working with minimal change.

Our Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: In stock typically ships in 1 week; no more than one month at the latest

- Payment: 50% advance payment; full balance due before delivery

- Express options: FedEx, UPS, DHL

- Pre‑shipment testing: Functional checks and visual inspection before dispatch

Key Features

- Centralized motion + logic control – Coordinates multi‑axis motion on fast packaging lines while executing PLC logic in one unit.

- SERCOS fiber ring – Typically SERCOS (commonly SERCOS II) for deterministic motion control with PacDrive servo drives and I/O stations.

- IEC 61131‑3 programming – Programmed with ELAU’s EPAS‑4 engineering suite, supporting Ladder, ST, FBD, and more.

- Ethernet service port – Standard 10/100 Ethernet for engineering, diagnostics, and file transfer.

- Fieldbus flexibility – Many installations use optional Profibus‑DP for third‑party I/O; serial service ports are often available for maintenance tools.

- Packaging‑optimized motion libraries – Camming, gearing, and registration functions suited to form‑fill‑seal, cartoners, and flow‑wrappers.

- Cabinet‑mount industrial design – Built for control cabinets with 24 VDC supply and straightforward wiring practices.

Technical Specifications

| Brand / Model | ELAU C600101100 (PacDrive C600 series controller) |

| HS Code | 853710 (Programmable control panels, ≤1000 V) |

| Power Requirements | 24 VDC control supply (typical) |

| Operating Temperature | 0…+50 °C (typical control cabinet conditions) |

| Communication Interfaces | SERCOS fiber‑optic motion bus; 10/100 Ethernet (engineering/service); optional Profibus‑DP; serial service (varies by option) |

| Signal I/O Types | Distributed I/O via SERCOS/fieldbus; local I/O via expansion options in many cases |

| Programming Environment | EPAS‑4 (IEC 61131‑3 languages; PacDrive libraries) |

| Installation Method | Control cabinet backplate mounting; follow EN 60204‑1 practices |

| Use Case | Central motion/logic controller for PacDrive systems in packaging and material handling |

Application Fields

You might notice that the C600 family shows up most often in packaging lines where fast, synchronized motion matters. Typical deployments include:

- Horizontal/vertical flow‑wrappers with registration control

- Cartoners, case packers, and tray formers

- Delta robot pick‑and‑place cells and top‑load systems

- Labeling, feeding, and infeed systems with conveyor tracking

- Format‑change applications with camming/gearing profiles

Advantages & Value

- Drop‑in compatibility – Keeps existing PacDrive drives, I/O, and EPAS‑4 projects, cutting retrofit time.

- Predictable performance – Deterministic SERCOS motion typically means smoother product handling and fewer quality rejects.

- Lower downtime risk – A like‑for‑like controller swap can recover production faster than a full platform migration.

- Lifecycle support – Access to engineering backups, firmware handling, and replacement parts that match your installed base.

- Total cost – In many cases, refurbishment plus verified testing is more cost‑effective than re‑engineering machines to a new platform.

Installation & Maintenance

- Cabinet environment – Mount on a clean, dry control cabinet backplate; allow space for ventilation and fiber‑optic bend radius. Maintain ambient 0…+50 °C.

- Power & grounding – Use a stable 24 VDC supply with proper PE grounding and separate the controller’s supply from noisy loads where practical.

- Network layout – Close the SERCOS fiber ring and label nodes; avoid tight fiber bends and route away from VFD power cables.

- Firmware & backups – Keep a verified EPAS‑4 project, parameter sets, and firmware package on hand. Back up the controller’s memory card if fitted.

- Routine checks – Inspect connectors, fiber ends, and cabinet filters. Replace the real‑time clock/retain battery if present (typically every 3–5 years).

- Safety – Lock out/tag out before service; verify emergency stop and guard circuits after any change.

Quality & Certifications

The PacDrive C600 series is generally supplied with CE conformity and, in many cases, UL/cUL recognition depending on the build. RoHS compliance can vary by production date for legacy hardware. Documentation and test reports are available on request. Manufacturer’s warranty on this unit: 365 days.

Supporting Components (Commonly Paired)

- SERCOS fiber‑optic cables and repeaters for PacDrive rings

- PacDrive‑compatible servo drives and distributed SERCOS I/O stations

- 24 VDC industrial power supplies with holdup/UPS where required

- Programming tools: EPAS‑4 software, Ethernet cable, and memory card (if the controller uses removable media)

One thing I appreciate is how quickly teams recover production with a like‑for‑like C600 swap. A maintenance manager from a confectionery plant told us their flow‑wrapper line was back making good product within the same shift—most of the time was just fiber cleaning and a quick EPAS‑4 download.

Reviews

There are no reviews yet.