Description

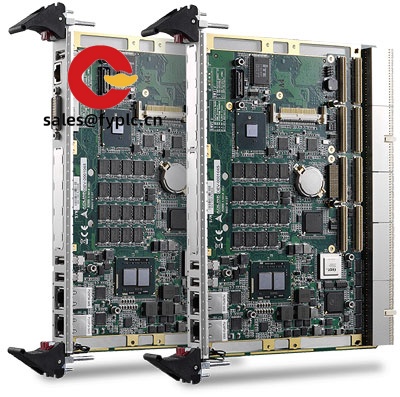

Advantech CPCI-680 CompactPCI System Controller – Reliable CPU Blade for Industrial Automation and Rugged Computing

The Advantech CPCI-680 is designed as a CompactPCI system controller for long-life industrial deployments. From my experience, it’s the kind of board you pick when you need stable x86 performance, dependable I/O on the front panel, and clean integration with a CompactPCI backplane in a 19-inch cabinet. You might notice that it balances traditional serial and video ports with Ethernet and USB, which makes retrofits and mixed-generation system builds much easier.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: typically 1 week ex-stock; no more than 1 month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

Key Features

- CompactPCI system-slot controller – Built for PICMG CompactPCI backplanes, ideal as the CPU blade in multi-slot systems.

- Industrial x86 architecture – Supports mainstream Windows and Linux distributions in most cases for easy application migration.

- Balanced I/O on the front panel – Typically includes Ethernet, serial, USB, and video, reducing add-on cards for common tasks.

- Backplane power and signaling – Draws regulated 3.3 V/5 V from the cPCI backplane, streamlining wiring and cabinet design.

- Long lifecycle availability – Advantech boards are known for extended supply and revision control, which simplifies spares management.

- Ruggedized for 24/7 service – Designed for stable operation in enclosed cabinets with proper airflow.

Technical Specifications

| Brand / Model | Advantech CPCI-680 |

| HS Code | 847150 (Processing units of ADP machines; commonly used for industrial CPU boards) |

| Power Requirements | From CompactPCI backplane (3.3 V / 5 V rails); typical system power 30–45 W depending on configuration |

| Form Factor | CompactPCI CPU blade; Eurocard format |

| Dimensions & Weight | Eurocard size; typical 6U board footprint 233.3 × 160 mm; approx. 0.7–0.9 kg depending on heatsink/front panel |

| Operating Temperature | 0 to 55 °C (standard); higher/extended ranges may be available by variant |

| Signal I/O (front panel) | Typically Ethernet, serial (RS-232/422/485), USB, and video (VGA/DVI) |

| Communication Interfaces | 10/100/1000 Ethernet, USB 2.0, serial ports; backplane signals per PICMG CompactPCI; some variants support PICMG 2.16 fabric |

| Installation Method | System-slot in CompactPCI chassis; front-access insertion with guide rails and ejector handle |

| OS Support | Windows and Linux distributions in most cases (version depends on CPU/chipset variant) |

Application Fields

This board fits well in industrial automation control, test and measurement rigs, power substation HMI/SCADA nodes, railway and transportation cabinets, and military/defense labs where CompactPCI remains the preferred standard. One thing I appreciate is how easily it slides into existing cPCI racks during phased upgrades—minimal re-cabling, quicker factory acceptance tests.

- PLC/SCADA gateways and redundant control CPUs

- AOI/test benches that need deterministic I/O alongside PC-class processing

- Legacy system modernization where cPCI backplanes must be retained

- Transportation onboard or wayside equipment with controlled thermal envelopes

Advantages & Value

- Reliability first – Designed for continuous operation; fewer field trips and service windows.

- Compatibility – Plays nicely with standard PICMG CompactPCI backplanes and common OS images.

- Lifecycle control – In many cases, Advantech maintains component consistency, easing validation and documentation.

- Cost containment – Reuse existing cPCI chassis and wiring; save on cabinet redesign and recertification.

- Support – We can assist with version matching, BIOS/firmware baselines, and image preloading to shorten commissioning.

Installation & Maintenance

- Cabinet & chassis – Use a 19-inch CompactPCI chassis with adequate airflow; maintain clear intake/exhaust paths.

- Power & wiring – Confirm backplane 3.3 V/5 V capacity; use shielded Ethernet and properly grounded serial cabling.

- ESD & safety – Insert/remove only with power off unless your system is explicitly hot-swap enabled; follow ESD procedures.

- Firmware & BIOS – Lock to a validated BIOS revision; schedule updates after lab tests, not in the field.

- Routine care – Quarterly dust removal in filtered cabinets; verify fan speeds and temperature alarms.

- Calibration/health checks – Run periodic memory and storage diagnostics; keep OS images and backups version-controlled.

“We swapped a legacy CPU blade for the CPCI-680 without touching the backplane wiring. The line was back up in under two hours.” — Feedback from an automotive test lab supervisor

Quality & Certifications

- Certifications: CE, FCC Class A, RoHS (typical for Advantech CompactPCI boards)

- Manufacturer policy: Advantech provides industrial-grade revision control and documentation; warranty terms vary by region and model

- Our coverage: 365-day warranty with technical support for configuration and replacement logistics

Recommended Supporting Components

- CompactPCI 19″ chassis with redundant hot-swappable PSUs and filtered front-to-back airflow

- Rear I/O transition module (RTM) matching the CPCI-680 pinout for clean cabling inside the cabinet

- PMC/XMC expansion modules for additional Ethernet, fieldbus, or storage if required by the application

- Industrial SSD or CFast storage pre-imaged with your OS and application stack

Note: Configurations of CPCI-680 may vary by CPU/chipset and I/O options. If you share your backplane model and target OS, we’ll match a CPCI-680 variant and validate power/thermal budgets before shipment.

Reviews

There are no reviews yet.