Description

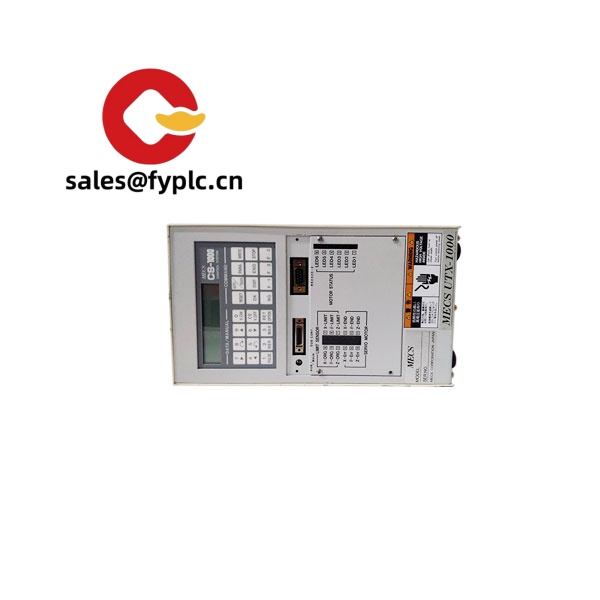

CS-1000 Capacitive Proximity Sensor for Level/Presence Detection

The CS-1000 is a compact, M30-style capacitive proximity sensor aimed at reliable level and presence detection on non-metallic bins, plastic bottles, glass jars, and even cardboard. From my experience, this type of sensor is what maintenance teams reach for when photoelectrics struggle with dusty windows or when ultrasonic is overkill. You might notice that the sensitivity dial makes it easy to tune through thin non-metallic walls, so you can detect media without direct contact—handy for food and beverage, chemicals, and packaging lines.

Our Order Placement Process & Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in-stock; no more than one month at the latest

- Payment: 50% advance payment, full payment before delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- Capacitive sensing with adjustable sensitivity – Detects liquids, powders, pellets, and plastics through non-metallic walls in many cases.

- M30 threaded barrel – Quick, rigid mounting with standard jam nuts; fits most existing brackets.

- 10–30 VDC supply – Easy to drop into standard 24 VDC machine panels.

- PNP or NPN switching output – Suits common PLC digital inputs; NO/NC logic typically configurable.

- IP67 protection – Resistant to splash and washdown; usually fine for industrial cabinets and machine frames.

- LED status indication – You can see at a glance if the sensor is triggered or powered, reducing troubleshooting time.

- Tune-through capability – One thing I appreciate is how you can detect media level without exposing the sensor to the process.

Technical Specifications

| Brand / Model | CS-1000 Capacitive Proximity Sensor |

| HS Code | 9031.80 (Other measuring/checking instruments – proximity sensing) |

| Power Requirements | 10–30 VDC, ripple < 10% (typical) |

| Signal Input/Output Types | 1x transistor switching output (PNP or NPN), NO/NC selectable (varies by version) |

| Operating Temperature | -25 to +70 °C (typical) |

| Housing / Protection | M30 barrel, nickel-plated brass or robust polymer; IP67 rating (typical) |

| Connection | M12 4-pin connector or potted cable (2 m), depending on variant |

| Installation Method | Threaded mount with locknuts; flush or non-flush mounting (as applicable) |

| Dimensions & Weight | Diameter M30; length typically 65–80 mm; ~120 g (connector version) |

| Communication Interfaces | Not applicable (discrete output sensor) |

Application Fields

This sensor fits both OEM builds and brownfield upgrades where space is tight and wiring must stay simple.

- Food & beverage: Tune through PET or glass to confirm liquid level in bottling lines.

- Chemical dosing skids: Dry-run protection on small tanks without direct product contact.

- Packaging: Carton presence and stack height detection where dust or film can confuse photoeyes.

- Plastics & rubber: Granulate level in hoppers; pellets are detected reliably in most cases.

- Textile & paper: Web/bobbin presence where reflective surfaces vary during shifts.

A maintenance manager told us their operators prefer this style because “it just keeps working even when the sight glass gets murky,” which seems to be the common experience on lines with fine powder.

Advantages & Value

- Reliable detection through non-metal walls – Typically reduces false trips compared to basic photoelectrics in dusty or foggy areas.

- Broad PLC compatibility – PNP/NPN options and 24 VDC power simplify wiring and spares strategy.

- Lower total cost – No need for sight ports or special fittings; installation is fast with M30 hardware.

- Service and stock support – Short lead times and a 365‑day warranty reduce downtime risk.

Installation & Maintenance

- Panel & cabinet – Use a clean 24 VDC supply; route sensor cabling away from VFD power cables to avoid noise.

- Mounting – Secure via M30 thread and locknuts; avoid metal mounting directly behind the sensing face to maintain sensitivity.

- Wiring – M12 4‑pin wiring: 24 VDC, 0 V, output, and teach/unused pin (varies by version). Verify PLC input type matches PNP/NPN selection.

- Calibration – Adjust the sensitivity dial with the process material in place; set a small margin above the switch point.

- Cleaning – Wipe the sensing face with a soft cloth; avoid solvents that may attack polymer windows.

- Routine checks – Quarterly function test; re-check setpoint after media changes (viscosity can slightly affect response).

Quality & Certifications

- CE conformity (EMC, LVD)

- RoHS compliant materials

- cULus listing typically available on standard variants

- Manufacturer’s warranty: 12 months (365 days)

Compatible Accessories (Optional)

- M12-4P-STRAIGHT – 4‑pin M12 cable, straight connector, PUR jacket for drag chains.

- MB30-L – Right-angle M30 mounting bracket with slotted holes for fine alignment.

- FN-SUPPRESS-24V – Inline noise filter for long cable runs near VFDs.

If you’re replacing an existing capacitive sensor, share your wiring (PNP/NPN), sensing distance, and thread size. We’ll confirm drop‑in compatibility and ship on the fastest available carrier.

Reviews

There are no reviews yet.