Description

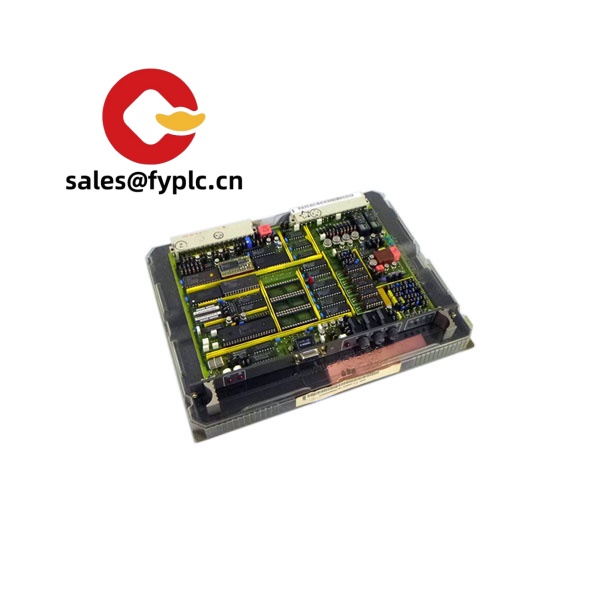

Honeywell DC-TDOB01 – Digital Output Termination Assembly for Experion/Series 8 I/O

The Honeywell DC-TDOB01 is a digital output termination assembly used with Honeywell Experion C300/Series 8 I/O. From my experience, it’s the piece that keeps wiring tidy and reliable—field devices on one side, the I/O module on the other—so you can add or replace hardware without touching dozens of conductors. You might notice that channel labeling and guided cable routing simplify commissioning, which typically cuts cabinet work hours and reduces rework during turnarounds.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment, full payment before delivery

- Express: FedEx, UPS, DHL

Key Features

- Digital output field termination – Purpose-built to interface DO channels from Honeywell Series 8 I/O to field devices like solenoid valves, relays, and indicator lamps.

- Clean wiring and labeling – Clearly marked terminals typically reduce wiring errors and make loop checks faster.

- I/O module friendliness – Works with the matched Series 8 DO I/O module so you can swap the module without disturbing field wiring.

- Per-channel status (where equipped) – Many installations use LED indication to help technicians spot a tripped channel or wiring fault in seconds.

- Compact footprint – High-density layout seems to be designed to save rail space and simplify cabinet layouts.

- Robust, industrial build – Suited for control rooms and MCC panels; typically handles the environmental conditions of standard DCS cabinets.

Technical Specifications

| Brand / Model | Honeywell DC-TDOB01 |

| Product Type | Digital Output Termination Assembly (Series 8 I/O family) |

| HS Code | 853890 (Parts for electrical control/switching apparatus) |

| Power Requirements | Uses cabinet/field 24 VDC distribution for DO circuits; termination assembly itself has minimal draw (LEDs if fitted). |

| Signal I/O Types | Digital Output channels, 24 VDC field-level wiring (commonly sourcing/PNP when paired with the corresponding I/O module). |

| Communication Interfaces | Backplane/connector interface to the matched Honeywell Series 8 DO I/O module; no external network port on the termination assembly. |

| Installation Method | Mounts inside a control cabinet on the designated Honeywell carrier/IOTA; field wiring via screw or spring-clamp terminals (per revision). |

| Operating Temperature | Typically 0 to +55°C in conditioned control cabinets |

| Dimensions & Weight | Standard Honeywell Series 8 termination assembly footprint; compact, cabinet-friendly design |

Application Fields

Typical deployments include oil & gas, chemicals, power generation, water/wastewater, and specialty manufacturing. It’s commonly used to drive:

- Solenoid valves for on/off valves and blowdown skids

- Interposing relays for motor starters and contactors

- Panel indicators, horns, beacons, and trip annunciators

- ESD/Shutdown logic outputs when integrated with the DCS (following plant SRS practices)

One thing I appreciate is how it keeps loops serviceable—techs can isolate a single output, check the LED, and get a clean point-to-point without guessing. In many cases that alone avoids an unnecessary shutdown call.

Advantages & Value

- Seamless compatibility – Built for Honeywell Experion/Series 8 I/O, so integration risks are minimal.

- Faster commissioning – Clear terminal layout and channel identification typically reduce loop-check time.

- Lower lifecycle costs – Stable part family with long-term Honeywell support; easier spares management.

- Reduced downtime – When paired correctly, module swaps don’t disturb field wiring, which speeds recovery.

“We swapped a failed DO module in under 10 minutes—no rewiring, no chasing terminals.” — Site maintenance engineer, upstream gas plant

Installation & Maintenance

- Cabinet environment – Install in a clean, ventilated control cabinet (IP54/NEMA 12 or better). Keep ambient within the stated operating range.

- Wiring practices – Use correctly rated 24 VDC supplies, segregate I/O from power cabling, and fuse field circuits as per plant standards. Verify polarity for sourcing DOs.

- Grounding – Maintain a low-impedance cabinet ground. Follow Honeywell grounding/bonding guidance to minimize noise and transient issues.

- Load interfacing – For inductive loads, include flyback suppression or use interposing relays as required by the application.

- Routine checks – Periodically inspect terminal tightness, clean dust, and verify channel operation during planned outages. Confirm controller firmware compatibility when adding/replacing I/O hardware.

Quality & Certifications

- Typically conforms to CE requirements for EMC and safety

- UL/cUL and RoHS compliance are commonly available for Honeywell Series 8 I/O families

- Manufacturer warranty per Honeywell policy (commonly 12 months)

- Our coverage: 365-day warranty with fast replacement support

If you’re standardizing on Honeywell Experion C300/Series 8, the DC-TDOB01 is a sensible choice for tidy, maintainable DO marshalling. If you can share your channel count, load types, and cabinet standards, I can confirm the exact revision and any accessories (fused carriers, interposing relay blocks) you might need.

Reviews

There are no reviews yet.