Description

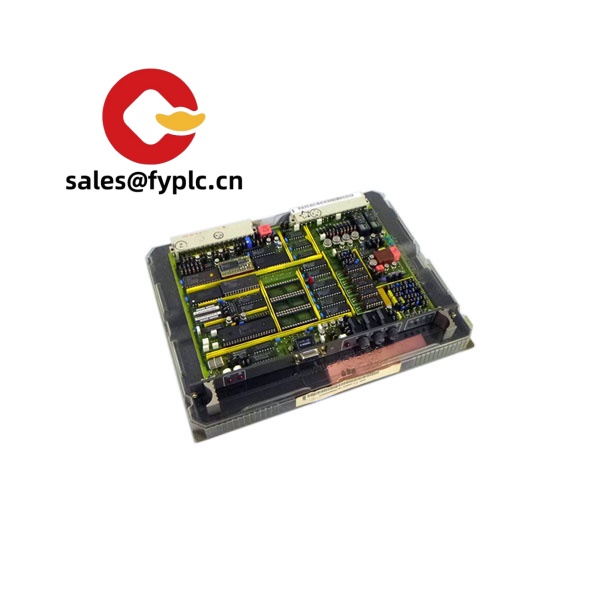

DDC4-10-40020 Direct Digital Controller – Compact control for 24 VDC industrial I/O and fieldbus integration

The DDC4-10-40020 is a compact Direct Digital Controller built for 24 VDC control cabinets, typically used to collect field signals, run simple logic, and exchange data with a PLC/SCADA host over common industrial protocols. From my experience, it slots nicely into OEM machinery, HVAC sub-panels, and skid systems where space is tight but reliability can’t be compromised.

Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than one month at the latest

- Payment terms: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

Key Features

- 24 VDC cabinet-ready – Designed for standard control panels; low power draw in most cases.

- Versatile I/O – Supports typical 24 VDC digital signals and common analog ranges (0–10 V / 4–20 mA), so it adapts to sensors and actuators you already use.

- Fieldbus connectivity – You might notice how quickly it joins Modbus RTU (RS‑485) or Modbus TCP networks, making SCADA handshakes straightforward.

- DIN-rail mounting – TS‑35 mounting saves time and keeps wiring neat in dense panels.

- Industrial temperature range – Built for typical plant conditions, reducing nuisance faults in warm cabinets.

- Service-friendly – Clear labeling and pluggable terminals (on most variants) make swaps fast during maintenance windows.

Technical Specifications

Application Fields

- OEM machinery and compact skids – Packaging, labeling, or dosing stations where quick I/O expansion is needed.

- HVAC and building systems – Fan coils, VAV boxes, pump groups; ties into existing BMS over Modbus easily.

- Water/Wastewater – Local pump control, lift stations, remote telemetry with simple setpoint logic.

- Process data acquisition – Collects analog trends (flow, temp, pressure) for SCADA historians.

- Retrofitting legacy panels – From my experience, it’s a clean way to add Ethernet/RS‑485 without overhauling the whole PLC.

Advantages & Value

- Reliable in real plants – Typically stable under electrical noise when grounded and wired correctly.

- Interoperable – Standard signal levels and Modbus mean fewer vendor lock‑ins and easier spares planning.

- Lower lifecycle cost – Simple configuration and DIN-rail form factor help reduce installation and service time.

- Practical support – Clear labeling and conservative I/O specs make troubleshooting straightforward for on‑site techs.

A packaging OEM told us they swapped in DDC4-10-40020 on a weekend shutdown—kept the 24 VDC wiring, pointed it to an existing Modbus TCP line, and had the machine running before Monday’s shift. That sort of drop‑in compatibility seems to be the main reason they standardize on it now.

Installation & Maintenance

- Panel environment – Install inside a ventilated control cabinet; keep ambient within the operating range and away from heat sources and VFDs when possible.

- Mounting – DIN‑rail TS‑35. Leave a small air gap on top/bottom for convection.

- Wiring – Use 24 VDC SELV power; segregate signal and power wiring. Shield and ground RS‑485 with a single‑point earth to minimize noise.

- Safety – De‑energize before working on terminals; verify polarity and I/O assignments to prevent miswiring.

- Routine maintenance – Periodic terminal re‑torque, dust removal with dry air, and backup of configuration. Firmware updates (if supported) during planned downtime.

- Calibration – For analog loops, verify 0–10 V and 4–20 mA scaling during commissioning and at scheduled intervals.

Quality & Certifications

- CE and RoHS compliance in most cases; UL/CSA listing may depend on the specific sub‑model and region.

- Manufactured under ISO 9001 quality systems (typical for this class of controller).

- Standard warranty: 12 months (365 days) from shipment.

Recommended Supporting Components

- 24 VDC DIN‑rail power supply (with ≥20% headroom for peak load)

- Shielded RS‑485 cable (twisted pair, 120 Ω characteristic impedance) and 120 Ω termination resistors

- DIN‑rail relay/isolator modules for inductive loads

- Industrial Ethernet switch (if using Modbus TCP) with metal housing and redundant power

- Surge/EMC protection on field lines where transients are expected

If you’d like, share your I/O count, network preference (RTU or TCP), and panel constraints. We can confirm compatibility and firm up delivery based on your project schedule.

Reviews

There are no reviews yet.