Description

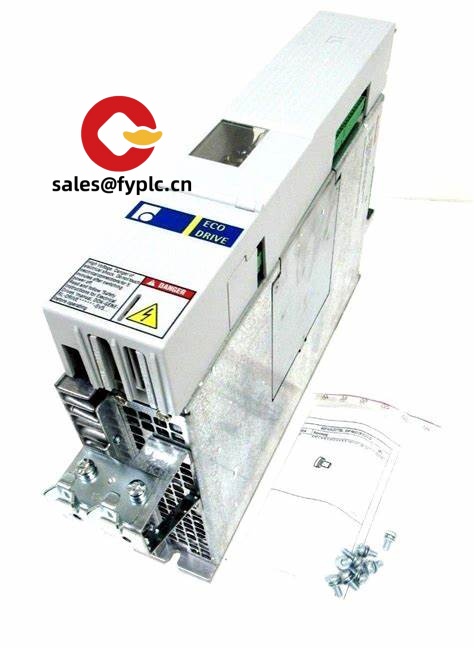

Kollmorgan DIGIFAS-7202 Digital Servo Drive – Precise motion control for compact servo axes

From my experience, the DIGIFAS-7202 is a solid choice when you need a reliable, cabinet-mounted servo amplifier for small to mid-power axes—indexing tables, feeders, compact gantries, that type of workload. You might notice that this part is sometimes mis-listed under Kollmorgen; it actually belongs to the Berger Lahr DIGIFAS 7200 family, which later aligned under Schneider Electric. One thing I appreciate is how easily it drops into legacy lines without forcing a PLC overhaul, especially where ±10 V analog control or step/direction commands are still the norm.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: typically 1 week if in stock; no more than one month at the latest

- Payment terms: 50% advance payment; full payment before delivery

- Express delivery options: FedEx, UPS, DHL

Key Features

- Digital servo amplifier for AC synchronous/BLDC motors – Typically used with Berger Lahr servo motors for precise positioning and speed control.

- Multiple command modes – Torque, velocity, and position modes are commonly available for flexible machine behavior.

- Friendly with legacy control signals – ±10 V analog, step/direction, and discrete I/O make retrofits straightforward.

- Encoder/resolver feedback support – Versions commonly support incremental encoder or resolver feedback, depending on the build.

- Service/parameter port – RS‑232 (in most cases) for commissioning and backup of parameters.

- Cabinet-mounted design – Compact footprint that fits well in tight control panels with standard mounting practices.

- Integrated brake control – Typically includes motor brake management to simplify wiring on vertical axes.

Technical Specifications

| Brand / Model | Kollmorgan DIGIFAS-7202(DIGIFAS 7200 series) |

| HS Code | 8504.40 (Static converters; includes servo drives) |

| Power Requirements | 230 V AC class, 50/60 Hz main supply; 24 V DC control supply (typical for the 7200 family; variant-dependent) |

| Operating Temperature | 0…40 °C in a ventilated control cabinet (typical usage) |

| Signal I/O Types | ±10 V analog, step/direction; digital enable/inhibit, home/limit inputs (common configurations) |

| Feedback Options | Incremental encoder or resolver (depending on version/options) |

| Communication Interfaces | RS‑232 service port; optional fieldbus variants (e.g., CANopen, Profibus, SERCOS) depending on model |

| Installation Method | Panel/cabinet mounting with proper grounding and EMC practices |

Application Fields

The DIGIFAS-7202 shows up a lot in packaging lines, labeling stations, light-duty robotics, electronics assembly, printing/marking, and conveyor indexing. In many cases it’s used for pick-and-place axes, web tension control, or precision feed mechanisms that need dependable positioning without overcomplicating the control architecture. It also suits retrofit projects where the original PLC sends ±10 V or step/direction signals and the goal is to stabilize uptime rather than redesign the entire drive system.

Advantages & Value

- Drop‑in compatibility – Typically integrates with existing Berger Lahr motor/feedback sets and cabinet wiring patterns.

- Lower integration risk – Keeps your PLC and field wiring intact; reduces commissioning time and unforeseen changes.

- Cost control – A practical alternative to migrating to a new platform when production windows are tight.

- Serviceability – Parameter backup via RS‑232 and well-understood wiring make maintenance predictable.

- Technical support – We can help with part identification (options/firmware) and swap strategies to minimize downtime.

“We replaced a failed 7202 on a carton feeder; kept the same motor and PLC analog output. Machine was back in production the same shift.” — Maintenance Supervisor, food packaging (typical feedback)

Installation & Maintenance

- Cabinet conditions – Mount in a ventilated, clean control cabinet; allow space for airflow. Keep ambient within 0…40 °C and below 95% non‑condensing humidity.

- Power and protection – Use correctly rated fusing/circuit breakers and a proper mains filter. Bond the PE ground with a short, low‑impedance connection.

- Wiring practices – Shield motor/feedback cables, separate power and signal wiring, and maintain correct phasing and brake control connections.

- Commissioning – Set motor parameters (feedback type, poles, current limits), tune loops conservatively, then refine with light loads.

- Routine care – Periodically vacuum dust from the cabinet, check connector torque, inspect encoder/resolver cables, and keep a parameter backup file. Firmware updates should only be performed with the approved tool and matching option set.

- Spare strategy – For critical stations, keeping one tested spare 7202 on the shelf typically pays for itself in the first avoided shutdown.

Quality & Certifications

- Manufacturer compliance: CE marking is common for the DIGIFAS 7200 family; UL recognition may apply depending on variant and market.

- RoHS: Legacy units may predate current RoHS revisions; confirm per serial/label when required by your compliance team.

- Warranty: 365 days hardware warranty from delivery.

- Traceability: We can document serial/firmware/options for QA records when you place the order.

If you’re matching a specific fieldbus, feedback option, or motor type, share a photo of the nameplate or the option code string on your existing unit. It seems to be the quickest way to avoid mix-ups within the 7200 variants.

Reviews

There are no reviews yet.