Description

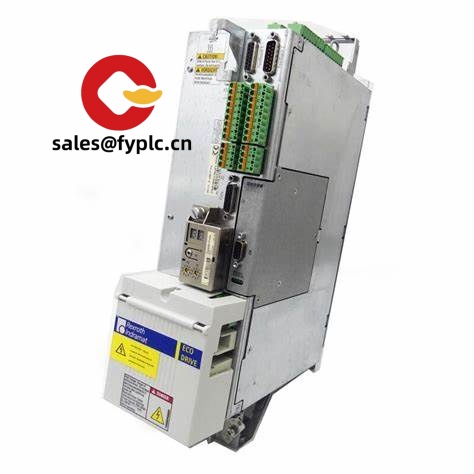

Bosch Rexroth DKC02.3-200-7-FW – ECODRIVE 03 Servo Drive for 400–480 V Motion Systems

The Bosch Rexroth DKC02.3-200-7-FW is part of the ECODRIVE 03 family, a workhorse servo drive you’ll typically find in packaging, printing, handling systems, and light machine tools. It’s designed for fast, repeatable positioning and speed control on 3-phase 400–480 V mains, and it pairs well with classic Indramat motors like MKD/MHD/MDD. One thing I appreciate is the modularity: the firmware module is replaceable and the command interface is plug-in, so you can match the drive to your control architecture without overhauling the whole cabinet.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment, full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- 400–480 V AC mains (3-phase) – The “-7-” voltage code indicates suitability for industrial 50/60 Hz grids, common in EU/US factories.

- Modular command interface – Supports various control options via plug-in cards (e.g., SERCOS, analog ±10 V, fieldbus variants), making retrofits simpler.

- Replaceable firmware module (-FW) – Firmware is carried on a removable card for easier updates or matching across multiple drives.

- DC bus sharing – Drives can share regenerative energy via L+/L- for improved system efficiency in multi-axis lines.

- Integrated diagnostics – Clear drive status and fault readout help maintenance teams shorten troubleshooting time.

- Compact booksize format – Cabinet-friendly footprint with forced-air cooling; typically installs side-by-side for multi-axis machines.

- Motor compatibility – Works with common Indramat servo motors (e.g., MKD/MHD/MDD series) with corresponding feedback options.

Technical Specifications

| Brand / Model | Bosch Rexroth DKC02.3-200-7-FW (ECODRIVE 03) |

| HS Code | 8504.40 (Static converters / servo drive) |

| Power Requirements | 3-phase 380–480 VAC, 50/60 Hz; internal fan cooling; DC bus link via L+/L- |

| Operating Temperature | 0 to +45 °C, non-condensing (typical for ECODRIVE 03) |

| Signal I/O Types | Digital I/O for enable/fault/reset; motor feedback via dedicated connector (incremental/absolute as equipped) |

| Communication Interfaces | Varies by command module; commonly SERCOS, analog ±10 V velocity/torque, and selected fieldbus options |

| Installation Method | Panel/cabinet mounting (vertical), forced-air ventilation; maintain top/bottom clearance |

| Protection Class | IP20 (cabinet use) |

| Firmware | Replaceable firmware module (-FW); version must match command interface |

Compatible Components & Accessories

- Indramat motors: MKD / MHD / MDD series (select feedback/cable set accordingly)

- Command modules: SERCOS or analog control cards (model varies by interface requirement)

- External braking resistor: for high-inertia deceleration duties

- Power and feedback cables: matched to motor/drive connectors and motor feedback type

Application Fields

From my experience, DKC02.3 units are a safe drop-in when you need predictable motion on legacy or mixed-generation lines. You might notice that OEMs keep them in packaging and converting equipment because of their reliability and the abundant spare parts base.

- Automated packaging (form-fill-seal, labeling, cartoners)

- Printing and converting (web handling, tension control with analog command)

- Material handling and robotics (pick-and-place, gantries)

- Light machine tools and assembly systems (indexing tables, feeders)

Advantages & Value

- Reliability – ECODRIVE 03 hardware is known to run for years with minimal drift; spare units are easy to commission thanks to the firmware card.

- Compatibility – Keeps older lines productive; supports typical field wiring and standard Indramat motor families.

- Cost control – Reuse your command interface and cables where possible; in many cases you avoid a full control upgrade.

- Supportability – Clear diagnostics and a large installed base reduce downtime and service learning curves.

Installation & Maintenance

- Cabinet and ventilation – Mount vertically on a conductive backplate in an IP54 (or better) enclosure; ensure clean airflow and space above/below for the fan exhaust.

- Wiring – Use shielded motor/feedback cables with proper grounding on both ends; keep power and signal routes separated to limit EMI.

- DC bus and braking – If sharing energy across axes, connect L+/L- per Rexroth guidelines; size external braking resistors for peak decel duty.

- Safety – Lock out/tag out mains before service; verify discharge of the DC bus (wait the specified time) and check with a meter.

- Routine care – Clean filters/fans periodically; inspect terminals for torque; back up parameters/firmware versions; update firmware only to validated revisions.

- Commissioning tip – Match the command module type and firmware to your PLC/NC. A quick parameter clone from a known-good unit typically shortens startup.

Quality & Certifications

- CE marked for EMC and Low Voltage compliance

- UL/cUL recognition for North American installations

- Manufactured to Bosch Rexroth quality standards; standard 12-month warranty

Field feedback: “We swapped a failed unit on a carton line with the same DKC02.3-200-7-FW, moved the firmware card and command module over, and were running in under an hour. Minimal tuning needed.” That seems to be the norm with these drives when the mechanics and motors haven’t changed.

Reviews

There are no reviews yet.