Description

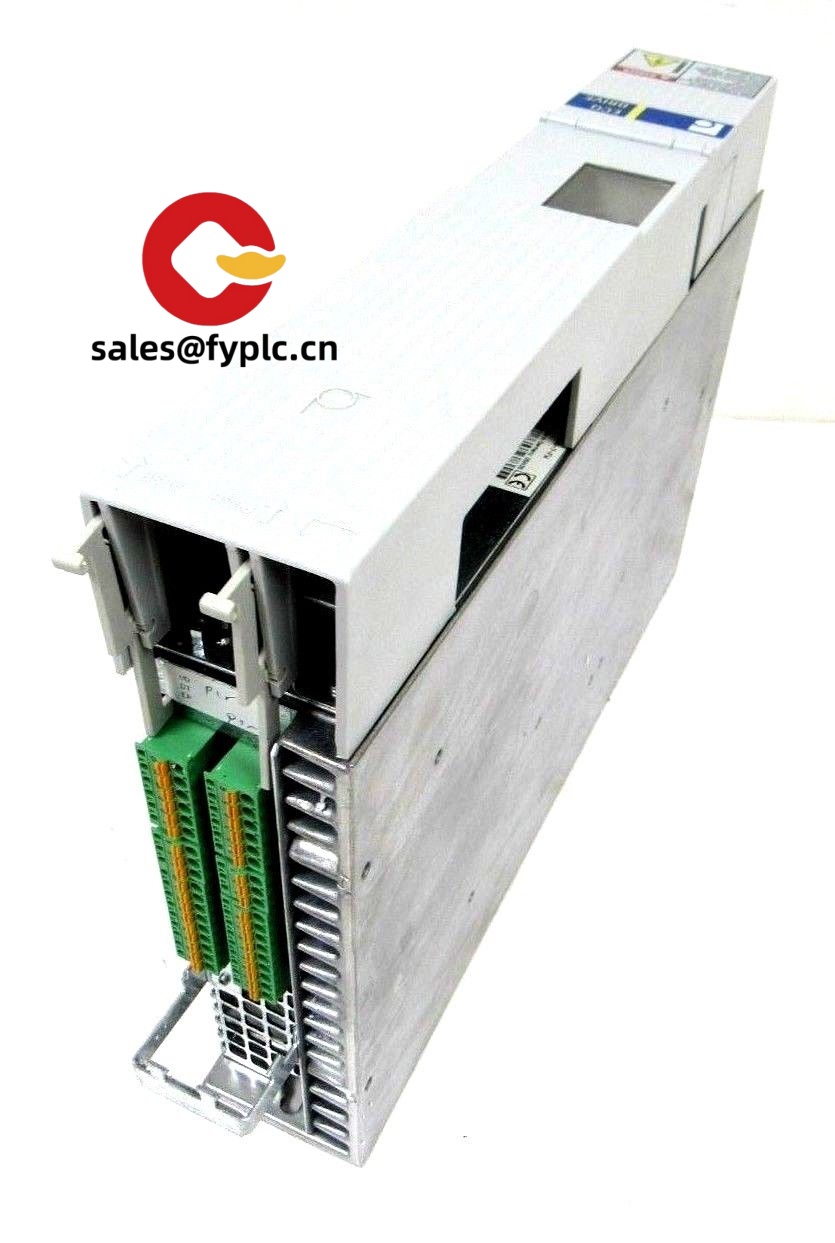

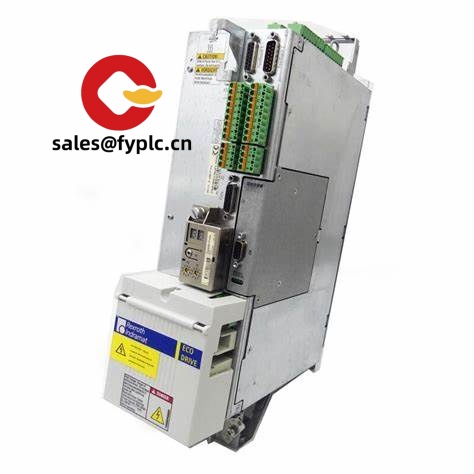

Bosch Rexroth DKCXX.3-040-7 – 40 A ECODRIVE 03 Servo Drive for 380–480 V Systems

The Bosch Rexroth DKCXX.3-040-7 is part of the ECODRIVE 03 family—well-regarded in retrofit and OEM projects for its steady performance, SERCOS-based control (on most .3 variants), and straightforward serviceability. From my experience, the “040-7” designation is the sweet spot for mid-to-high power axes: 3-phase 380–480 VAC mains with a 40 A class output stage. It typically pairs with Rexroth Indramat synchronous or asynchronous servomotors (e.g., MKD/MHD/2AD series), giving you a durable, field-proven motion platform without fuss.

Our Order Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week for in‑stock items; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Shipping: FedEx, UPS, DHL (express)

Key Features

- 40 A power stage on 380–480 VAC mains – Handles demanding axes in packaging, machining, and converting lines without running hot in most cases.

- SERCOS-based control (.3 generation) – Deterministic fiber‑optic motion bus widely used on multi‑axis machines; analog ±10 V command options exist on specific firmware variants.

- 24 VDC control supply – Keeps diagnostics and fieldbus alive during mains-off; useful for safe stops and staged power-downs.

- Integrated braking chopper – External resistor connection for dynamic deceleration and energy dissipation during aggressive moves.

- Rich I/O and feedback – 24 V digital I/O for enable/fault handling; resolver or digital encoder feedback depending on the motor/firmware combination.

- Service-friendly design – Plug-in terminaling and clear status LEDs make commissioning and swap-outs faster than many newer, more complex platforms.

Technical Specifications

| Brand / Model | Bosch Rexroth DKCXX.3-040-7 (ECODRIVE 03 family) |

| HS Code | 8504.40 (Static converters / servo drive) |

| Power Requirements | 3‑phase 380–480 VAC, 50/60 Hz; control supply 24 VDC (typical) |

| Rated Output Current | 40 A class (040 frame) |

| Operating Temperature | 0 to +45 °C without derating; up to +55 °C with derating (typical) |

| Signal Input / Output | 24 VDC digital I/O; analog ±10 V command on some variants; fault relay contact |

| Communication Interfaces | SERCOS fiber‑optic (common on .3); variant-dependent fieldbus options |

| Motor Feedback | Resolver or digital encoder (depending on motor and firmware) |

| Braking | Integrated chopper; external braking resistor connection |

| Installation Method | Control cabinet mounting (IP20), vertical orientation, forced‑air cooling |

| Dimensions & Weight | Approx. 390 × 110 × 300 mm; ~10 kg (varies slightly by sub‑variant) |

Application Fields

- Packaging and filling lines – Fast indexing axes and synchronized conveyors.

- Machine tools and retrofits – Spindle and feed axes where a sturdy 40 A stage is needed.

- Printing and converting – Register control, web handling, and winding applications.

- Material handling and robotics – Medium‑to‑high torque joints with stable velocity loops.

- Woodworking and plastics – Saws, routers, and extruder drives with frequent start/stop cycles.

Advantages & Value

- Proven reliability – ECODRIVE 03 hardware tends to run for years with minimal drift, which cuts unplanned downtime.

- Compatibility – Works with a wide range of Rexroth Indramat motors and common SERCOS masters used on legacy lines.

- Cost control – Ideal for maintaining existing assets without a full controls redesign; typically shortens validation cycles.

- Service ecosystem – Spare parts, fiber loops, and feedback cables are readily available, which simplifies maintenance planning.

Installation & Maintenance

- Cabinet and ventilation – Mount vertically in an IP54+ cabinet; keep 100–150 mm clearance for airflow; avoid dust and oil mist.

- Wiring practices – Use shielded motor and feedback cables; bond shields 360° at entry; provide a solid PE; fit line reactors if mains distortion is high.

- Braking resistor – Size per application inertia and duty; ensure sufficient cooling and resistor over‑temperature protection.

- Safety – Hard‑wire STO/enable as per your risk assessment; lockout/tagout before servicing; verify discharge time of DC bus.

- Routine care – Quarterly dust cleaning; check fan and filter condition; review error logs; firmware/parameter backups kept offline.

- Commissioning tips – Start with conservative current/velocity limits; perform feedback alignment; verify motion direction before full torque.

Recommended Accessories & Companion Parts

- SERCOS fiber‑optic patch cables (F-SMA), short and long runs for multi‑axis rings.

- External braking resistor matched to the 040 frame chopper rating for high‑inertia moves.

- Motor power and feedback cable sets for MKD/MHD/2AD motors (resolver or encoder types).

- Line reactor or mains choke where THDi or supply stiffness is a concern.

- 24 VDC control power supply with adequate hold‑up for controlled stops.

“We swapped a failed DKC drive on a packaging axis with a DKC..3‑040‑7 and were back in production the same shift. The SERCOS ring recognized it immediately after restoring parameters.”

Quality & Certifications

- Conforms to CE directives; many variants carry UL/cUL recognition

- Designed to IEC/EN 61800 drive standards

- RoHS compliance depends on production year and variant; documentation available on request

- Manufacturer warranty practices typically supported; our warranty: 365 days

If you’re migrating from an older DKC0x.3 unit or consolidating spares, you might notice that keeping the 040‑frame on hand covers a surprising number of mid‑power axes. Share your current motor type and control interface, and we’ll verify firmware and accessory matching before shipment.

Reviews

There are no reviews yet.