Description

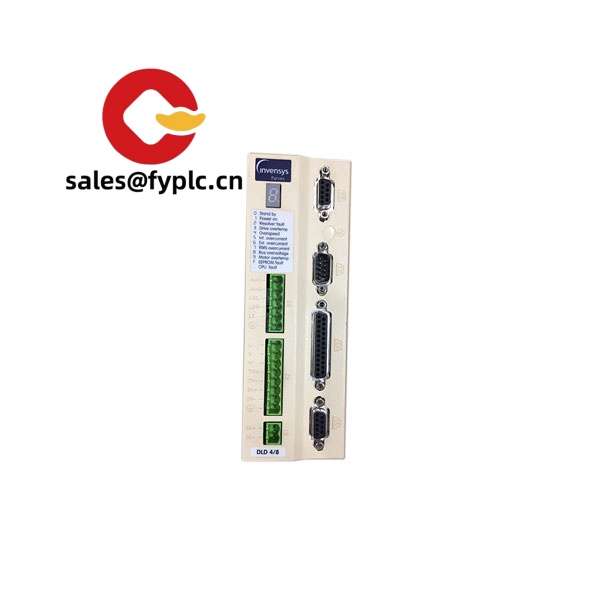

Parker DLD13004R – DC servo drive for brushed motors, 130 V class, 4 A continuous

The Parker DLD13004R is a compact, panel‑mount DC servo amplifier from the DLD series, typically used to run brushed DC servomotors in speed or torque mode. If you’re maintaining legacy equipment or upgrading a single axis without changing the entire control system, this model tends to be a practical, low‑risk choice. It accepts an analog command, supports standard feedback, and the “R” suffix generally indicates a regenerative/braking capability and RoHS‑compliant build.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in-stock; no more than one month at the latest

- Payment method: 50% advance payment, full payment for delivery

- Express delivery methods: FedEx, UPS, DHL

Key Features

- 130 V class, 4 A continuous output – Suits a wide range of brushed DC servomotors on small to medium axes.

- Analog command (±10 V) – Easy drop‑in with classic PLC/IPC motion cards; no re‑architecting your control strategy.

- Speed or torque mode – Select what your machine needs: stable velocity regulation or tight torque control.

- Regenerative capability (“R” suffix) – Handles deceleration energy more gracefully; helps reduce external braking hardware in many cases.

- Standard feedback support – Typically works with a DC tachometer and, in many builds, incremental encoder feedback for speed loop integrity.

- Panel‑mount, compact form factor – Fits straightforwardly into existing cabinets; wiring is familiar to maintenance teams.

- Industrial I/O – Enable/Inhibit inputs, status/fault indication, and a relay output for interlocks.

- Robust tuning options – On‑device adjustments for gain/balance make commissioning quick with a handheld meter and scope.

Technical Specifications

| Brand / Model | Parker DLD13004R (DLD series DC servo drive) |

| HS Code | 8504.40 (Static converters / servo amplifiers) |

| Power Requirements | Single‑phase 115/230 VAC, 50/60 Hz (typical for this series) |

| Output Rating | 4 A continuous armature current; 130 VDC class armature voltage |

| Control / Command | ±10 V analog (speed or torque mode), enable/inhibit input |

| Signal I/O & Feedback | Digital enable, fault relay, status LEDs; DC tachometer input and, in many cases, incremental encoder support for speed feedback |

| Communication Interfaces | None (analog interface; no fieldbus on standard builds) |

| Operating Temperature | 0 to 40 °C (typical cabinet conditions) |

| Installation Method | Panel‑mount inside control cabinet; vertical orientation with free airflow |

| Dimensions & Weight | Compact module; DLD series units are typically around 200 × 120 × 65 mm, ~1.2 kg (confirm against your unit’s nameplate) |

Application Fields

From my experience, the DLD13004R fits best in retrofit or expansion projects where a brushed DC servomotor is already specified. You might notice that it shows up often in:

- Packaging and labeling lines – speed control on feeders, sealers, and film drives

- Material handling – indexing tables, pick‑and‑place axes, small conveyors

- Winding/Unwinding – torque regulation for tension control on legacy stations

- Test stands and lab automation – simple torque mode control with analog command

- Machine tool auxiliaries – spindles or feed drives on older equipment where analog interface is preferred

Advantages & Value

- Drop‑in compatibility – Keeps your existing PLC/motion card architecture; typically no fieldbus rework.

- Predictable commissioning – Analog tuning and standard feedback make it straightforward for maintenance teams.

- Lifecycle savings – Extends machine life without a full servo platform migration; spare‑part friendly.

- Stable supply and support – We source verified units and back them with a 365‑day warranty.

Installation & Maintenance

- Cabinet & cooling – Mount vertically on a grounded metal backplate inside an IP54 (or better) cabinet. Leave clearance above/below (typically 100 mm) for convection airflow.

- Power & grounding – Use a dedicated circuit with proper fusing/MCB. Bond PE earth with a low‑impedance connection. Add an EMC mains filter near the drive input if emissions are a concern.

- Wiring – Keep motor/feedback cables shielded and routed away from mains. Verify tach polarity during speed loop setup. Use ferrules and torque terminals per the manual.

- Tuning – Start with conservative gain; confirm zero‑command drift (balance/offset) before enabling. Log final pot settings for future service.

- Routine checks – Quarterly dust cleaning, tighten terminals, inspect for heat discoloration. Encoder/tach connections should be checked if speed ripple appears.

- Protective devices – Where regen is heavy, ensure braking components are rated correctly. Fit a line reactor if your site has high mains distortion.

Quality & Certifications

- CE marked; UL/CSA recognition common on Parker DLD series builds

- RoHS compliance typically indicated by the “R” suffix

- Manufactured under Parker’s ISO 9001 quality system

- Backed by our 365‑day warranty on supplied units

Related and Supporting Components

- Brushed DC servomotor matched to 130 V class, 4 A continuous (Parker legacy DC motors with tachometer are commonly paired)

- DC tachometer or incremental encoder kit for feedback, depending on your control scheme

- EMC mains filter, line reactor, and appropriate fuses/MCB

- Shielded motor/feedback cables and a braking resistor if your duty cycle demands it (even though “R” models handle regen better)

One thing I appreciate is how forgiving the DLD13004R can be during retrofits—most teams get it running quickly with a meter, a small scope, and good wiring discipline. If your application has unusual feedback or rapid decel cycles, share the duty profile and we’ll sanity‑check the match before you place the order.

Reviews

There are no reviews yet.