Description

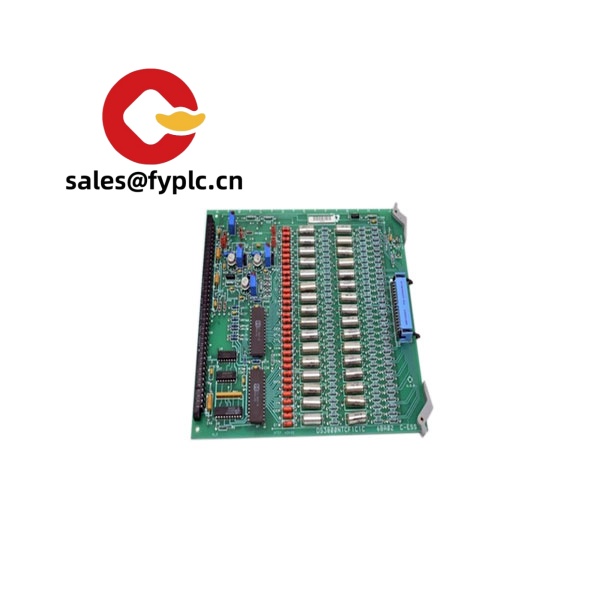

GE DS3800DMPK1E1D – Microprocessor Control Board for Speedtronic Mark IV Turbine Systems

The GE DS3800DMPK1E1D is a microprocessor control board used in Speedtronic Mark IV gas and steam turbine control racks. From my experience, this board typically handles core sequencing and coordination functions in the Mark IV logic set, working hand-in-hand with I/O and memory cards through the backplane. If you’re maintaining a legacy Mark IV panel and want a form‑fit‑function replacement, this model tends to be a direct drop-in when matched by revision.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery time: 1 week for in‑stock; no more than one month at the latest

- Payment: 50% advance payment, full payment for delivery

- Express options: FedEx, UPS, DHL

Key Features

- Mark IV backplane compatibility: Designed to operate on the GE Speedtronic Mark IV bus for seamless integration.

- Microprocessor-based control: Executes sequencing and coordination tasks that keep turbine logic deterministic.

- On-board diagnostics: You might notice status LEDs and test points that simplify fault localization during outages.

- Socketed firmware components: PROM/EEPROM locations (when fitted) allow revision alignment to your turbine’s configuration.

- Rack-powered via backplane: Typically uses regulated 5 V logic power with auxiliary rails supplied by the Mark IV rack.

- Form-fit-function replacement: The K1E1D revision sequence seems to be widely used across multiple Mark IV panels, which reduces retrofit risk.

- Service-friendly design: Card guides, keyed connectors, and extractor levers make changeouts fast during planned outages.

Technical Specifications

| Brand / Model | GE Speedtronic Mark IV / DS3800DMPK1E1D |

| HS Code | 8538.90 (Parts suitable for apparatus of 8535/8536/8537) |

| Power Requirements | Backplane supplied; typically 5 VDC logic (aux ±15 VDC rails present in the rack as needed) |

| Dimensions & Weight | Standard Mark IV rack card format; board-level module, typically under 0.5 kg |

| Operating Temperature | 0 to 60 °C typical (panel must meet Mark IV environmental specs) |

| Signal I/O Types | Digital/backplane bus interfacing; logic-level signaling via edge/backplane connectors |

| Communication Interfaces | Proprietary GE Mark IV backplane bus; on-board diagnostic header where fitted |

| Installation Method | Slides into Mark IV rack card guides; mates to keyed backplane connectors; secured with front hardware |

| Typical Position | Processor/control slot within the Mark IV core logic bay (verify slot per panel drawings) |

| Revision Notes | K1E1D indicates a specific hardware/firmware combination; match to site spares list before ordering |

Application Fields

Commonly used in GE Speedtronic Mark IV turbine panels across:

- Gas turbine control for power generation (Frame units and aero-derivative packages)

- Steam turbine logic coordination in industrial utilities

- Oil & gas compression and pipeline stations using legacy Mark IV controls

- Petrochemical plants retaining installed Mark IV fleets for reliability reasons

Advantages & Value

- Operational continuity: Form-fit replacement helps you avoid unplanned logic changes or revalidation.

- Compatibility: When matched by firmware and jumpers, it typically synchronizes cleanly with existing I/O and memory cards.

- Cost control: Extends the life of installed Mark IV assets without a costly controls retrofit.

- Lead-time flexibility: In-stock units can ship quickly to support planned outages or emergent repairs.

- Technical backing: We can assist with revision checks, slot position confirmation, and basic commissioning pointers.

Installation & Maintenance

- Environment: Install in a clean, ventilated control cabinet meeting Mark IV specs; avoid condensation and corrosive gases.

- ESD handling: Use a grounded wrist strap; keep the board in antistatic packaging until ready to insert.

- Backplane care: Inspect and gently clean card-edge connectors; reseat to ensure a uniform mate across the connector.

- Revision alignment: Verify PROM labels, jumper positions, and board revision E1D against your panel’s configuration sheet.

- Power-up checks: Run Mark IV self-tests; confirm status LEDs and alarm-free operation before returning the unit to service.

- Routine maintenance: Dust with dry air during outages; review firmware consistency during any logic change management.

Quality & Certifications

- Quality process: Functional testing on dedicated fixtures; burn-in reports available for many units.

- Certifications: CE/UL typically apply at the system (panel) level for Mark IV installations; components may use UL-recognized parts.

- RoHS: As a legacy industrial board, RoHS applicability varies; many installed-base spares are non-RoHS by design.

- Warranty: 365 days coverage from delivery.

To speed up verification, feel free to share your existing DS3800DMPK part label photos (including the K1E1D suffix and any PROM IDs). We’ll double-check compatibility with your specific Mark IV rack and confirm lead time.

Reviews

There are no reviews yet.