Description

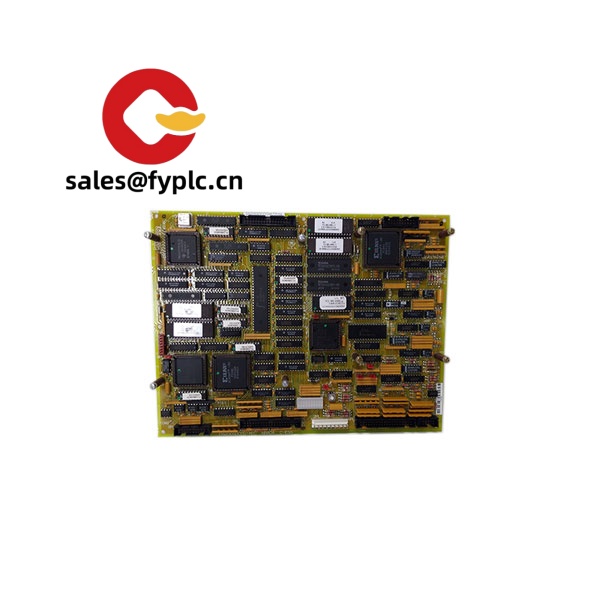

GE DS215TCQAG1BZZ01A – Mark V TCQA Analog I/O Board for Gas/Steam Turbine Control

The GE DS215TCQAG1BZZ01A is a TCQA-series analog I/O board used in Speedtronic Mark V turbine control systems. From my experience, this board is typically found in the R/S/T cores handling mixed analog signal conditioning and data acquisition, feeding critical process values to the control logic. Compared with DS200 versions, the DS215 variant usually integrates revised firmware and component enhancements that improve compatibility across more Mark V frames.

One thing I appreciate is how it drops into existing Mark V racks with minimal fuss—most sites swap it like-for-like, re-seat the personality/firmware devices, run a quick calibration check, and bring the unit back online. It seems to be a reliable path for plants keeping legacy turbines running efficiently without a full system migration.

Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week for in‑stock items; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express: FedEx, UPS, DHL

Key Features

- Mixed analog I/O handling – Typically manages conditioned 4–20 mA and low‑voltage analog signals used across Mark V turbine loops.

- On-board signal conditioning – Filtering, scaling, and A/D conversion for stable readings under electrical noise common in turbine halls.

- Backplane integration – Direct interface to the Mark V rack; no external protocol rework required.

- Firmware-ready DS215 variant – Usually ships with updated firmware support compared to DS200 equivalents, easing cross-revision replacement.

- Compatible terminal boards – Works with the associated terminal hardware (often TBQA/TBQC in many cabinets), simplifying field wiring continuity.

- Service-friendly design – Clear test points and keyed connectors speed up diagnostics and board swaps during outages.

Technical Specifications

| Brand / Model | GE (General Electric) / DS215TCQAG1BZZ01A |

| HS Code | 853890 (Parts for industrial control/switchgear assemblies) |

| Power Requirements | Supplied by Mark V rack backplane; typically +5 VDC logic and ±15 VDC analog rails (low power, < 15 W total in most cases) |

| Dimensions & Weight | Standard Mark V rack card; approx. 280–330 mm board length; ~1.0 kg (varies slightly by revision) |

| Operating Temperature | Typically 0 to +60 °C within a ventilated cabinet environment |

| Signal I/O Types | Mixed analog inputs/outputs (e.g., 4–20 mA, low-voltage analog); discrete I/O supported via terminal boards; exact channel count depends on cabinet configuration |

| Communication Interfaces | Mark V backplane bus interface; field wiring via associated terminal boards (no front-panel Ethernet) |

| Installation Method | Rack-mounted plug-in PCB for Mark V card cage; secured with captive hardware; ESD-safe handling required |

Application Fields

This board is commonly used in:

- Gas and steam turbine control – Analog measurement and conditioning for fuel, temperature, pressure, and speed-related loops.

- Balance-of-plant integration – Interfacing auxiliary analog signals (valves, pumps, lube oil systems) through the Mark V core.

- Life-extension projects – Reliable spare for legacy Mark V fleets where downtime costs are high.

A maintenance lead at a combined-cycle site told us a DS215TCQAG1BZZ01A swap shaved hours off their restart window because wiring stayed untouched at the terminal board and only backplane alignment and verification were needed.

Advantages & Value

- Reliability – Proven in harsh plant environments; stable readings under vibration and electrical noise.

- Compatibility – Drop-in fit for Mark V racks; typically works with existing terminal boards and firmware sets.

- Cost control – Extends system life without a full DCS migration; reduces engineering change effort.

- Support – We help with part matching (revisions, artwork, and firmware considerations) to avoid surprises during outages.

Installation & Maintenance

- Environment – Install in a clean, ventilated control cabinet meeting Mark V standards; avoid condensation and dust.

- Wiring – Keep field wiring on the associated terminal boards; verify tightness, shielding, and grounding continuity.

- ESD & Safety – Power down, discharge, and follow ESD precautions; handle by edges; confirm backplane alignment before tightening.

- Commissioning – Load/verify the correct firmware set; run loop checks and analog scaling verification.

- Routine care – Periodic connector reseat during planned outages, light dust cleaning, and signal calibration checks; firmware updates applied only after a configuration backup and test window.

Quality & Certifications

- Manufacturing standards – Typically produced under ISO 9001 quality systems for GE industrial controls.

- Compliance – System-level UL/CE compliance is usually cabinet-dependent; RoHS status may vary by vintage due to legacy components.

- Warranty – 12-month coverage (365 days); units are function-tested prior to dispatch.

If you need us to check interchangeability with DS200-series TCQA boards or to confirm terminal-board pairings (often TBQA/TBQC depending on your frame), share your cabinet photos or BOM and we’ll validate before you schedule downtime.

Reviews

There are no reviews yet.