Description

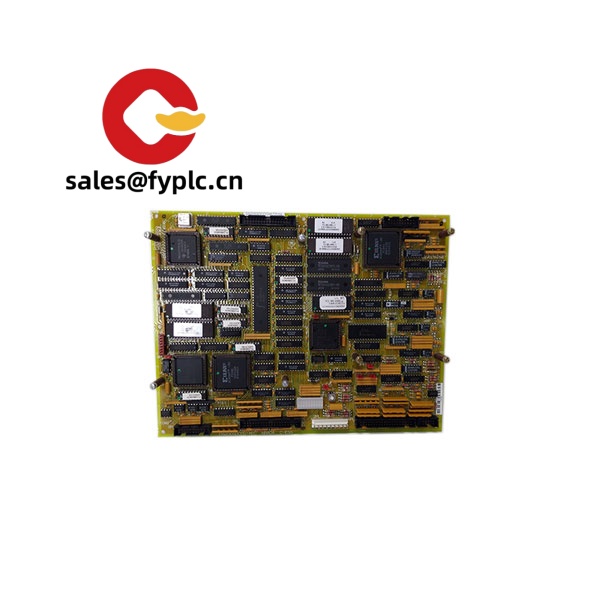

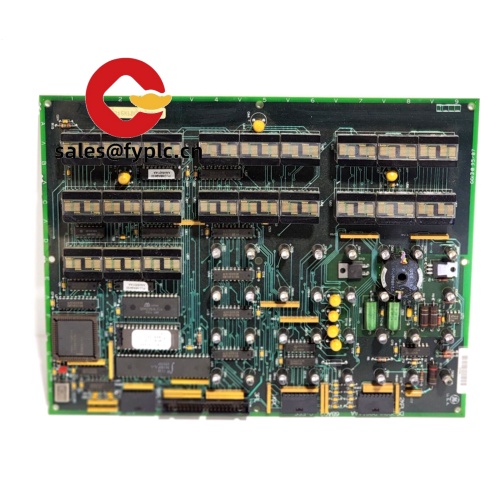

GE DS215SDCCG1AZZ01A – Drive Control Card for GE Industrial Drives

The GE DS215SDCCG1AZZ01A is a Drive Control Card (SDCC) used as the central control board in many GE drive systems—typically DC2000, AC2000, and EX2000. From my experience, it’s the board that closes your speed/torque loops, manages I/O with the rest of the cabinet, and keeps the application logic running reliably. You might notice that DS215 variants are often conformal-coated for better environmental resilience, which helps in cabinets that see dust or moisture.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Central drive control – Executes motor control algorithms for speed/torque regulation and coordinates feedback and protection.

- Mixed analog/digital I/O – Handles reference signals, feedback, and interlocks through the drive’s backplane and mating terminal boards.

- Conformal coating (DS215 series) – In many cases improves resistance to humidity and airborne contaminants in industrial cabinets.

- Drop-in replacement – Designed as a field-replaceable module; typically backward-compatible with DS200SDCCG1 family revisions (always verify firmware/options).

- Firmware-based logic – Application parameters stored on-board; supports standard GE commissioning tools for tuning and diagnostics.

- Stable operation – Seems to be preferred by maintenance teams because it boots fast and keeps legacy lines running without rewiring.

Technical Specifications

| Brand / Model | GE DS215SDCCG1AZZ01A (SDCC Drive Control Card) |

| HS Code | 853890 (Parts for electrical control panels/equipment) |

| Power Requirements | Supplied by host drive backplane; logic +5 VDC and ±15 VDC analog rails (typical) |

| Operating Temperature | 0 to 60°C inside a properly ventilated control cabinet (typical) |

| Signal I/O Types | Mixed analog references (e.g., ±10 V), digital I/O and feedback via backplane/terminal boards; supports encoder/tach feedback through related interface modules |

| Communication Interfaces | Backplane links to peripheral cards; service access via system HMI or optional RS‑232/RS‑485 interfaces depending on cabinet configuration |

| Installation Method | Plug-in PCB mounted on standoffs within GE drive rack; ribbon and edge connectors to mating boards |

Application Fields

You’ll typically find the DS215SDCCG1AZZ01A in retrofit and spare-part programs across continuous process plants. It fits well when production cannot tolerate long migrations:

- Steel and metals processing lines (rolling, pickling, annealing)

- Paper and converting machines needing tight speed matching

- Mining, cranes, and hoists where torque control is critical

- Oil & gas auxiliary drives and test stands

- General industrial drives in legacy GE DC2000/AC2000/EX2000 cabinets

Advantages & Value

- Reliability in the field – One thing I appreciate is how these boards stabilize older lines; downtime tends to drop because the parameters and wiring remain familiar.

- Compatibility – Usually a direct replacement in cabinets already using SDCC. Minimizes re-engineering and preserves existing I/O.

- Cost control – Extends the life of installed GE drives, avoiding a full system migration and the re-validation costs that come with it.

- Technical support – Parameter backups and firmware guidance help get you back online quickly if a board fails unexpectedly.

Customer note: A maintenance lead on a metals line told us their backup DS215SDCCG1AZZ01A swapped in under two hours, with only a quick loop-tune to hit spec—no wiring changes.

Installation & Maintenance

- Environment – Install in a closed control cabinet with clean, dry air and adequate ventilation. Keep ambient temperature within the drive’s specified range.

- Wiring – De-energize the cabinet, observe ESD precautions, and verify ribbon/edge connectors seat fully. Route low-level analog signals away from high-voltage cabling.

- Start-up – Load or verify parameters, check feedback polarity (tach/encoder), and run a controlled ramp to confirm loop stability.

- Routine care – Quarterly visual checks for contamination or loose connectors; light dust removal with dry air; review alarms and update firmware when recommended by your drive documentation.

- Spares strategy – Keep one programmed spare per critical line; label the PROM/EEPROM set with date and revision to avoid mix-ups.

Quality & Certifications

- Manufacturing quality system: ISO 9001 (GE production systems)

- Typically installed in CE/UL-compliant drive systems; cabinet-level compliance applies

- RoHS status may vary by production year for legacy boards; lot-specific confirmation available

- Warranty: 365 days replacement/repair

Related/Supporting Components

Commonly paired with GE terminal and interface boards in the same cabinet, such as encoder/tach interface modules and I/O terminal boards that carry field wiring. If you’re replacing a DS200SDCCG1 variant, this DS215 version is frequently the practical path when improved environmental resistance is desired—just verify option codes and firmware.

Reviews

There are no reviews yet.