Description

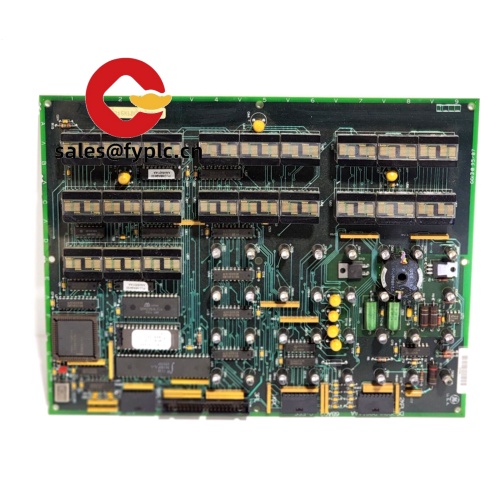

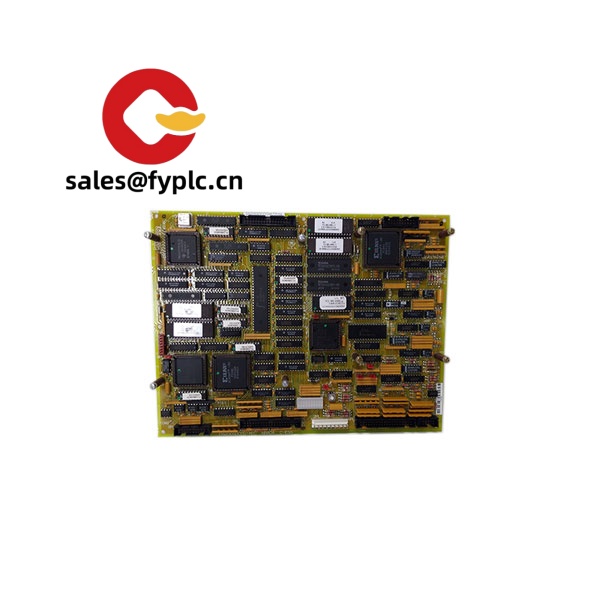

GE DS215KLDCG1AZZ03A – Local Digital Control board for Mark V / EX2000 platforms

The GE DS215KLDCG1AZZ03A is a Local Digital Control (LDC) controller board used across many GE industrial control platforms—most commonly Mark V Speedtronic turbine controls and EX2000/LS2100 excitation systems. From my experience, it’s the card that quietly carries the main control logic and coordination, handling the I/O network, sequencing, and diagnostics so the rest of the system stays in sync. If you’re maintaining legacy turbines, static starters, or excitation cabinets, this is typically the drop-in module maintenance teams keep on the shelf to cut downtime to a minimum.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery time: 1 week for in-stock units; no more than one month at the latest

- Payment terms: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Drop-in replacement – Designed to fit GE Mark V / EX2000 rack positions with existing backplane connectors.

- On-board application firmware – The DS215 variant typically ships with the required firmware set installed, reducing swap-over time.

- Dual IONet channels – Provides redundant I/O network paths for robust controller-to-I/O communications in most cabinets.

- Backplane powered – Receives regulated logic power from the system backplane; wiring stays neat and predictable.

- On-board diagnostics – Front LEDs and self-check routines help technicians confirm health at a glance after startup.

- Conformal coating – DS215 boards are commonly conformal-coated for better performance in industrial environments.

- Serviceable firmware devices – Field-replaceable memory devices (PROM/EPROM) make version alignment straightforward when required.

Technical Specifications

| Brand / Model | GE DS215KLDCG1AZZ03A |

| Product Type | Local Digital Control (LDC) controller board |

| HS Code (reference) | 853890 – Parts for electrical control apparatus |

| Power Requirements | Backplane-supplied 5 VDC logic power (typical) |

| Operating Temperature | 0 to 50 °C in a control cabinet (typical) |

| Signal I/O Types | Backplane digital buses; no direct field I/O termination on the board |

| Communication Interfaces | IONet A/B (redundant cabinet network); service/maintenance header where fitted |

| Installation Method | Plug-in rack card; mates to system backplane; secured with front hardware |

| Coating | Conformal-coated (DS215 series, typical) |

Application Fields

You’ll typically find the DS215KLDCG1AZZ03A in:

- GE Mark V Speedtronic gas and steam turbine control panels (core controller positions)

- EX2000 and LS2100 excitation/static starter systems where IONet redundancy matters

- GE industrial drive cabinets (as the supervisory/logic controller in certain builds)

- Power generation, petrochemical, and large process plants with legacy Mark V infrastructure

One thing I appreciate is how it slots into mixed fleets—many plants still run Mark V turbines alongside newer units, and this board keeps the older cabinets maintainable without forcing a controls migration.

Advantages & Value

- Reliability – Proven architecture; stable operation in temperature-controlled enclosures.

- Compatibility – Matches GE backplane pinout and IONet topology used in Mark V/EX2000 cabinets.

- Reduced downtime – Preloaded firmware in many cases means faster swap and re-commissioning.

- Lifecycle support – Practical for plants extending the service life of legacy GE systems.

- Procurement clarity – Clear HS Code classification for customs and smoother cross-border shipments.

A maintenance supervisor told us they keep at least one DS215 LDC on the shelf because “when an IONet path starts acting up, a quick board swap isolates the problem fast.” That seems to mirror what we hear at other combined-cycle sites.

Installation & Maintenance

- Environment – Install in a closed control cabinet with steady ventilation; avoid dust ingress and condensation.

- ESD safety – Use grounding straps and ESD-safe handling; avoid touching components and edge contacts.

- Seating & wiring – Power down fully; insert the board evenly into the backplane; secure the front hardware; confirm IONet cabling and terminations.

- Firmware alignment – Match firmware revisions and site configuration; back up parameters before swap when applicable.

- Post-install checks – Verify LED status, IONet redundancy, and controller health via cabinet HMI/diagnostics.

- Routine care – Quarterly light dust removal with dry, oil-free air; review event logs; apply firmware updates only when validated for the site.

Quality & Certifications

- Manufacturing quality systems: ISO 9001 at the OEM level (typical for GE production)

- CE/UL conformity: Typically applicable at the system level when installed in GE cabinets

- RoHS: Varies by build and year; many DS215 boards are not strictly RoHS due to legacy components

- Warranty: 365 days

Note: Certain sites require the exact AZZ03A firmware set to match existing controllers. If you’re replacing a like-for-like board, sharing your cabinet model and current firmware label helps ensure plug-and-run results.

Reviews

There are no reviews yet.