Description

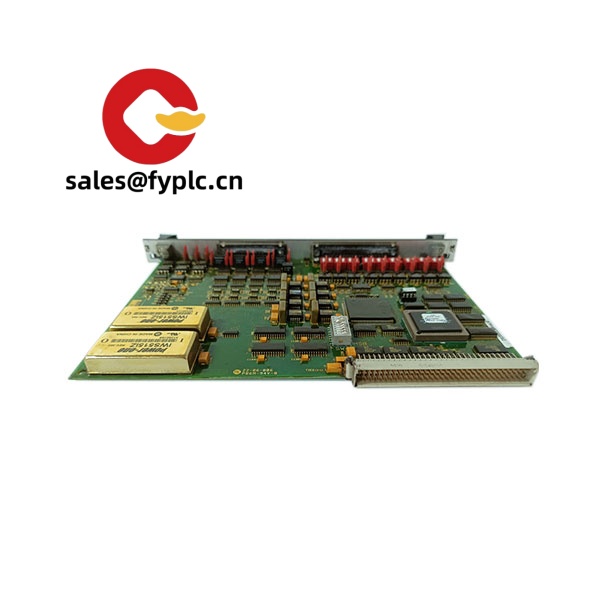

GE DS200TBCAG1AAB Terminal Board – Reliable field I/O termination for GE control cabinets

The GE DS200TBCAG1AAB is a TBC-series terminal board used to land and organize field wiring in GE control systems. From my experience, this model typically sits inside Mark V turbine control panels and GE industrial drive/excitation cabinets, providing clean, labeled screw terminals for discrete and low-voltage signal runs. You might notice that it’s a passive, robust board—no firmware to manage—built to keep signal wiring tidy, shielded, and serviceable.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: In-stock typically ships in 1 week; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

- Order flow: Confirm model/revision → Receive quotation → Place PO & prepay → Functional testing & packing → Balance payment → Express dispatch

Key Features

- Purpose-built terminal landing – Organized screw-type barrier strips for clean field wiring, reducing wiring errors and rework.

- Passive, no firmware – No configuration required; drop-in wiring interface that simplifies commissioning.

- Noise-conscious layout – Trace spacing and grounding provisions that, in many cases, help with industrial EMC and signal integrity.

- Service-friendly labeling – Clear channel markings; maintenance teams can trace circuits quickly during outages.

- Revision AAB – A later hardware revision that is typically backward-compatible within the TBC series envelope.

- Cabinet-ready form factor – Mounts to backpanels or subplates inside GE control cores; pairs with ribbon/plug harnesses to controller I/O cards.

Technical Specifications

| Brand / Model | GE DS200TBCAG1AAB (TBC series terminal board) |

| HS Code | 853890 (Parts for switchgear/control apparatus) |

| Power Requirements | Passive board; no separate power input (carries signal-level wiring) |

| Dimensions & Weight | Board-level assembly; typical TBC length mid-sized for GE control cores (lightweight, easily panel-mounted) |

| Operating Temperature | Cabinet environment; typically 0–60°C when installed per GE panel standards |

| Signal I/O Types | Field termination for discrete and low-voltage signals; shielded pairs and common returns supported |

| Communication Interfaces | Not applicable (termination interface to controller I/O via harness/ribbon) |

| Installation Method | Panel/backplate mounting; screw terminals for field wires; plug-in harnesses to mating controller cards |

Application Fields

This board is commonly found in:

- GE Speedtronic Mark V gas and steam turbine control cabinets

- GE industrial drives and excitation systems where DS200-series I/O termination is required

- Balance-of-plant panels handling status contacts, interlocks, permissives, and alarm fan-outs

- Retrofit/upgrade projects needing a like-for-like TBC board replacement to reduce downtime

A maintenance supervisor recently shared: “Swapping in DS200TBCAG1AAB took us less than an hour. Terminals lined up with our drawings and the harness mated straight away. No surprises during the restart window.”

Advantages & Value

- Reliability in harsh cabinets – The board layout and materials handle vibration and electrical noise typical of turbine halls and MCC rooms.

- Compatibility – Intended as a direct fit in DS200/TBC locations; in many cases, revision AAB is backward-friendly within the TBC family.

- Downtime reduction – Clear labeling and screw terminals speed field replacement during tight outage windows.

- Cost control – Practical alternative to redesigning wiring looms; keeps existing harnessing and documentation usable.

- Support – We assist with model and revision checks against your cabinet BOM, helping avoid mismatches.

Installation & Maintenance

- Cabinet environment – Install in a clean, ventilated enclosure. Maintain adequate spacing from high-heat sources and high-frequency drives.

- Wiring practices – Use ferrules or properly crimped lugs; segregate low-level signals from power cabling; route shield drains to designated ground points.

- Torque & labeling – Tighten terminals to the recommended torque; verify terminal numbering against cabinet drawings before energization.

- ESD handling – Treat as a PCB assembly; use grounding straps and antistatic packaging during handling.

- Routine checks – Periodically re-torque terminals, inspect for discoloration or loosened shields, and remove dust with dry, oil-free air.

- No firmware upkeep – As a passive termination board, there are no configuration files or firmware updates to maintain.

Quality & Certifications

- Typically used within CE/UL compliant control panels when integrated to applicable standards

- Manufacturing quality aligned with industrial control norms (ISO-based processes at OEM level)

- RoHS applicability may vary by production year; many legacy boards predate full RoHS adoption

- Warranty: 365 days (repair/replace)

Related/Supporting Components

Plants often pair the DS200TBCAG1AAB with DS200-series controller I/O cards and other termination boards. Common companions include DS200TCQA/TCQC controller interfaces and additional TBC/TBQ boards for expanded I/O. If you share your cabinet BOM or photos, we can verify inter-board compatibility before shipment.

Reviews

There are no reviews yet.